Fabricated thermal insulation wallboard material containing straw-based wood ceramic lightweight aggregate and preparation method thereof

A technology for wood ceramics and thermal insulation wall panels, applied in the field of building materials, can solve the problems of long demoulding time, waste of resources, low production efficiency, etc., achieve high social and environmental benefits, improve water resistance and durability, shorten the The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

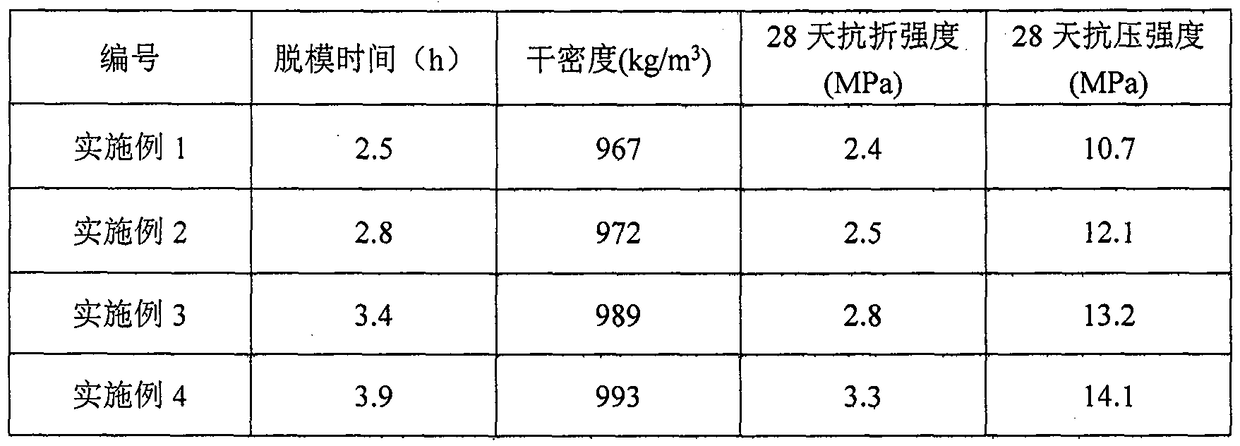

Embodiment 1-4

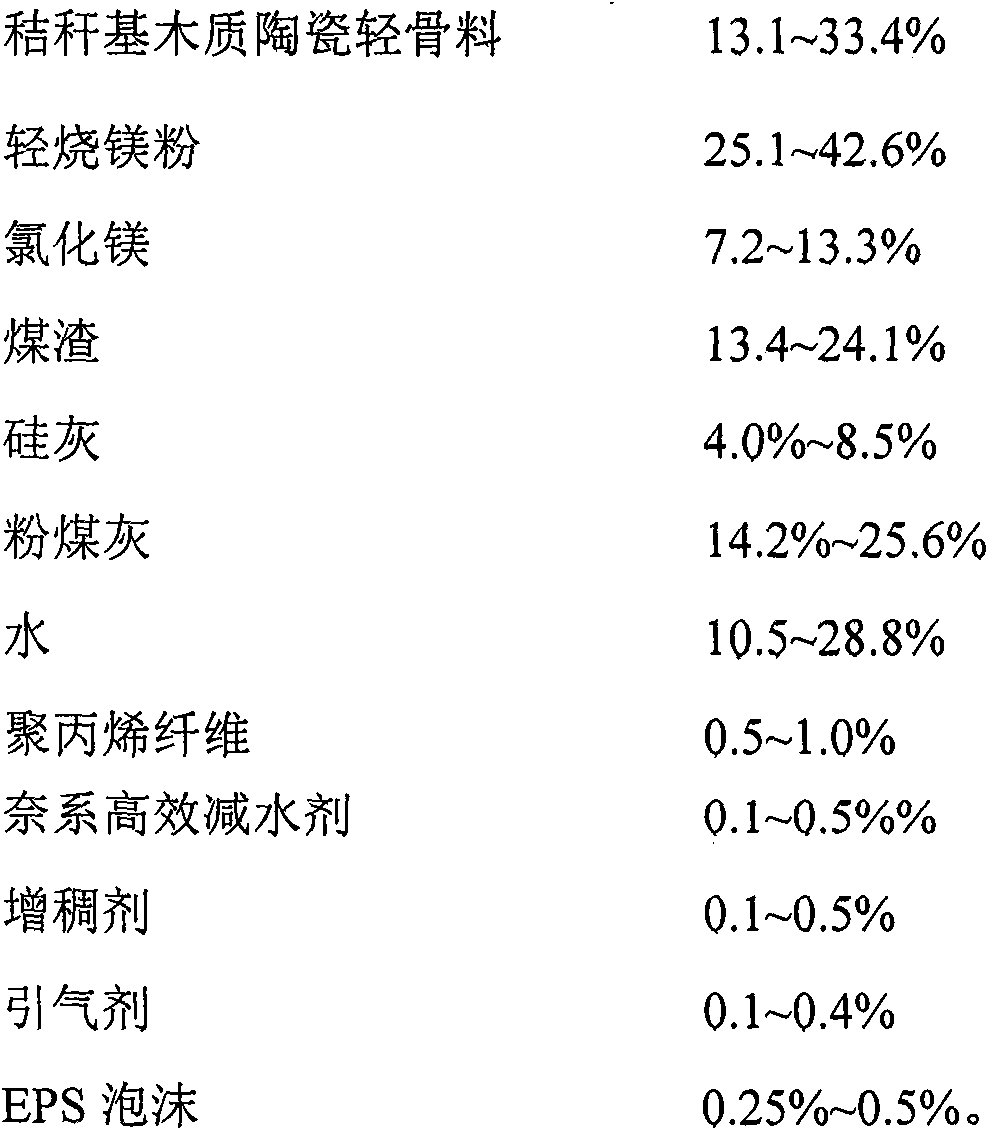

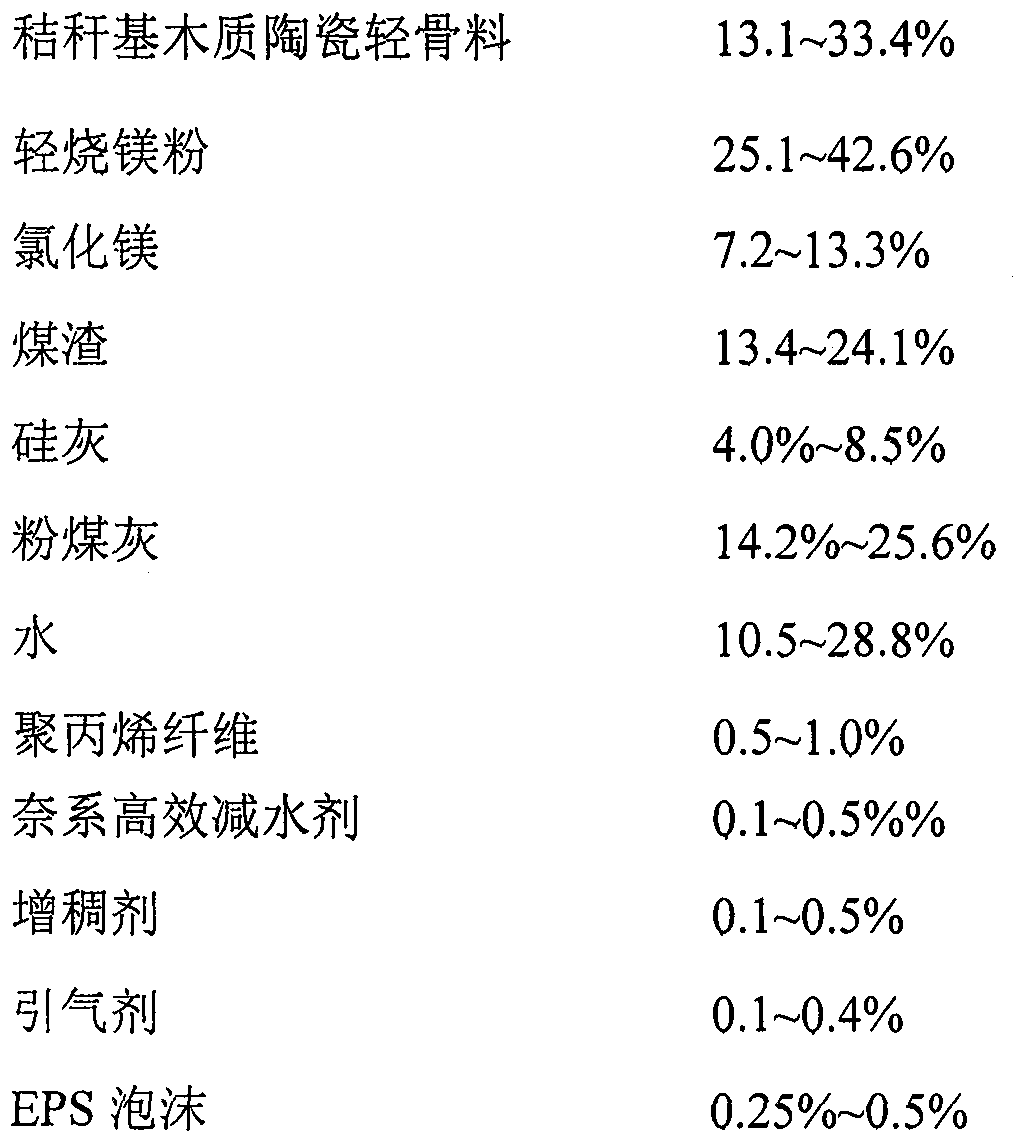

[0037]A prefabricated thermal insulation wallboard material containing straw-based wood-ceramic lightweight aggregate prepares the following raw materials according to the mass percentage:

[0038] The above-mentioned weighed materials are prepared according to the following steps:

[0039] (1) Pour the weighed dead-burned magnesia, potassium dihydrogen phosphate, borax, and silica fume into the stirring container, and stir for 30 seconds until the materials are evenly mixed;

[0040] (2) Take a suitable container, pour the weighed air-entraining agent, thickener, and wood calcium into the weighed water, and stir for 30 seconds until all the liquids are evenly mixed;

[0041] (3) Pour the stirred liquid into the blender, first stir at a low speed for 15s, then stir at a high speed for 30s to make a fluid slurry;

[0042] (4) Pour the weighed cinder and straw-based wood ceramic light aggregate into the mixer, first stir at low speed for 30s, then stir at high speed for 30s; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com