Double-body activated carbon vacuum sulfurizing device and using method thereof

An activated carbon and double-body technology, which is applied in the field of double-body activated carbon vacuum sulfurizing devices, can solve the problems of unsatisfactory sulfurized samples, expensive glove boxes, and low sample output, and achieve the effects of avoiding condensation, avoiding waste, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

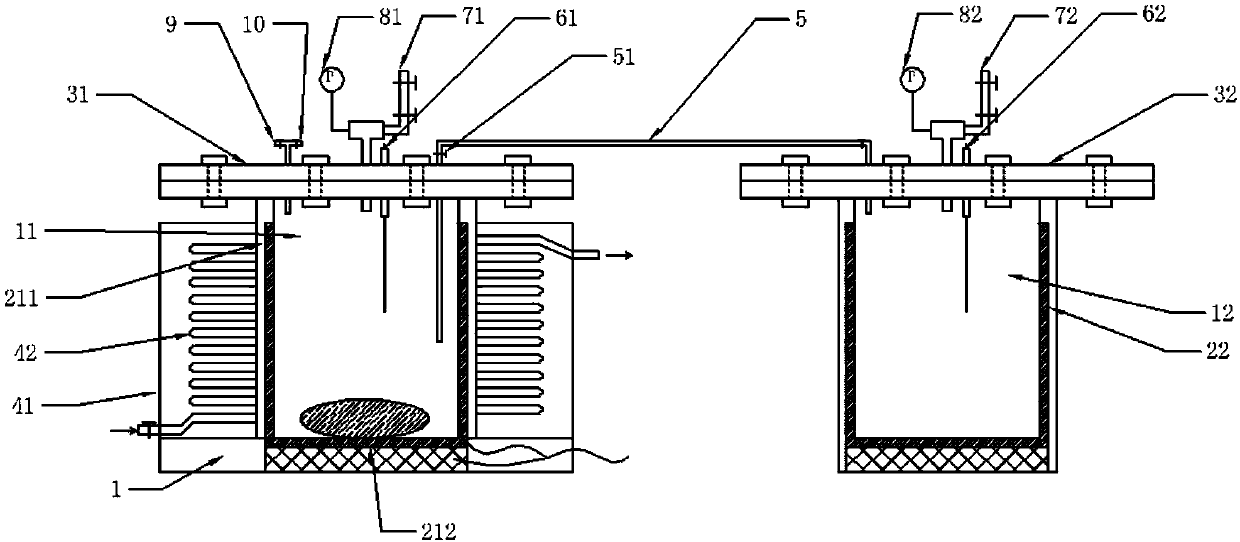

[0022] A double-body activated carbon vacuum sulfurizing device, comprising a carbon-setting kettle body 11 and a sulfur-setting kettle body 12, a carbon kettle sealing cover 31 is arranged on the top of the carbon-setting kettle body 11, a sulfur kettle sealing cover 32 is arranged on the top of the sulfur-setting kettle body 12, and a sulfur kettle body 12 is provided with a sulfur kettle sealing cover 32. A sulfurizing tube 5 is arranged between the sealing cover 32 and the carbon kettle sealing cover 31, and the two ends of the sulfurizing tube 5 respectively pass through the sulfur kettle sealing cover 32 and the carbon kettle sealing cover 31 communicate with the still cavity of the sulfur kettle body 12 and the charcoal kettle body 11 , the outside of the sulfur kettle body 12 is provided with a sulfur kettle heating device 22, and the outside of the charcoal kettle body 11 is provided with a charcoal kettle heating device, and a nitrogen gas inlet pipe 10 and a vacuum ex...

Embodiment 2

[0029] A method of using the above two-body activated carbon vacuum sulfurizing device:

[0030] Step 1, put activated carbon in the carbon kettle body 11, put sublimated sulfur in the sulfur kettle body 12, seal the carbon kettle sealing cover 32 and the sulfur kettle sealing cover 31;

[0031] Step 2. Close the nitrogen inlet valve, open the sulfurizing valve 51, start the heating devices 211 and 212, set the temperature at 105°C, open the vacuum pumping valve and start pumping until the pressure gauge 81 of the carbon kettle and the pressure gauge 82 of the sulfur kettle The readings are all less than 20mTorr;

[0032] Step 3: Close the sulfur seepage valve 51, open the heating device 22, set the temperature at 95.35°C, until the value index of the sulfur kettle pressure gauge 82 is stable, close the exhaust valve, close the charcoal kettle heating devices 211 and 212, and open the charcoal kettle cooling device 41, Drop to room temperature until the temperature of the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com