Production process for corrosion-resistant glass fiber composite fabric

A glass fiber compounding and production process technology, applied in the textile industry, can solve the problems of less mass production processes, reduce labor intensity, ensure printing and dyeing quality, and improve production efficiency and production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

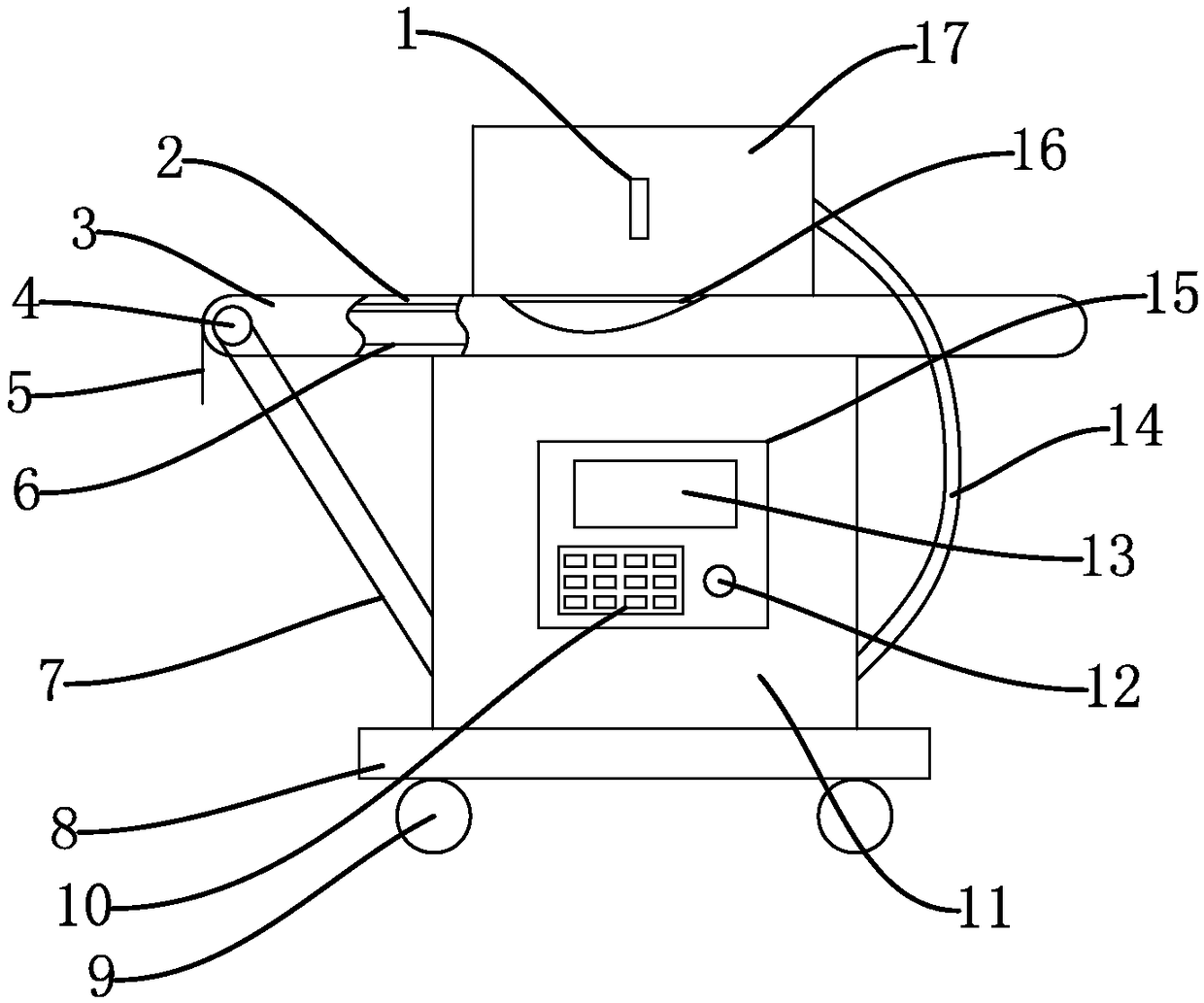

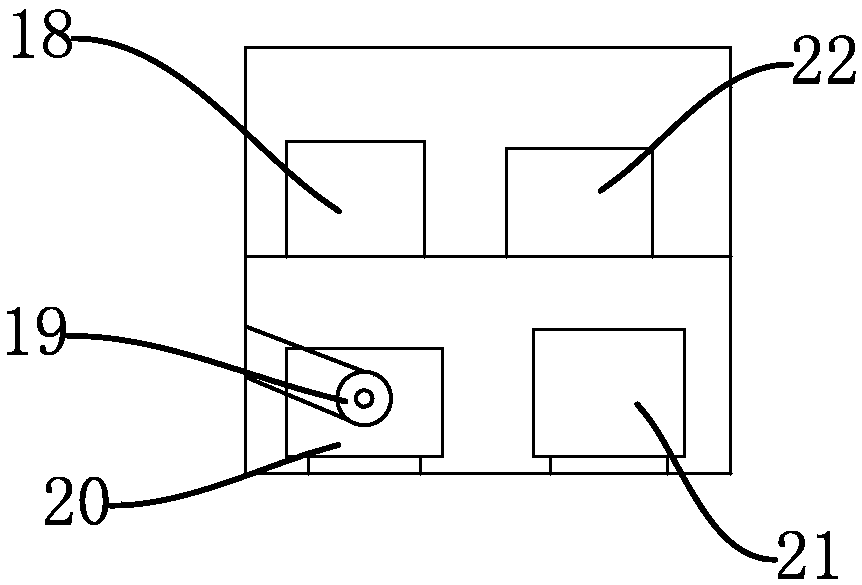

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

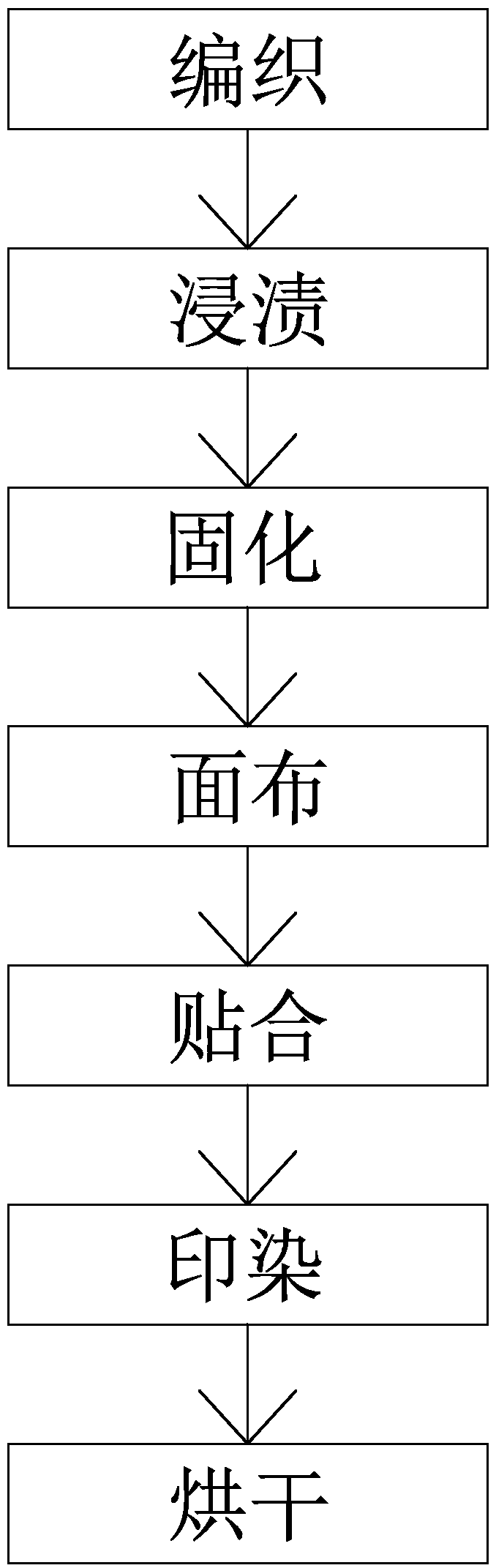

[0031] Such as Figure 1-Figure 4 Shown, a kind of production process of corrosion-resistant glass fiber composite cloth, this process comprises the following steps:

[0032] a. Weaving: flat weave the glass fiber monofilament to obtain the basic glass fiber cloth;

[0033] b. Impregnation: immerse the basic fiberglass cloth in the slurry for 5-6 hours in step a;

[0034] c. Curing: Then carry out ultraviolet curing to the basic glass fiber cloth impregnated in step b;

[0035] d. Face cloth: use non-woven fabrics on the market for processing, apply corrosion-resistant paint on the non-woven cloth, and dry to obtain corrosion-resistant face cloth;

[0036] e. Bonding: Laminate the UV-cured glass fiber cloth and the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com