Preparation for supported type noble metal-based catalyst using core-shell structure MOF as reaction vessel and application of catalyst

A core-shell structure and reaction vessel technology, applied in the preparation of carbon-based compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems of few research reports and achieve simple preparation methods, not easy to lose, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

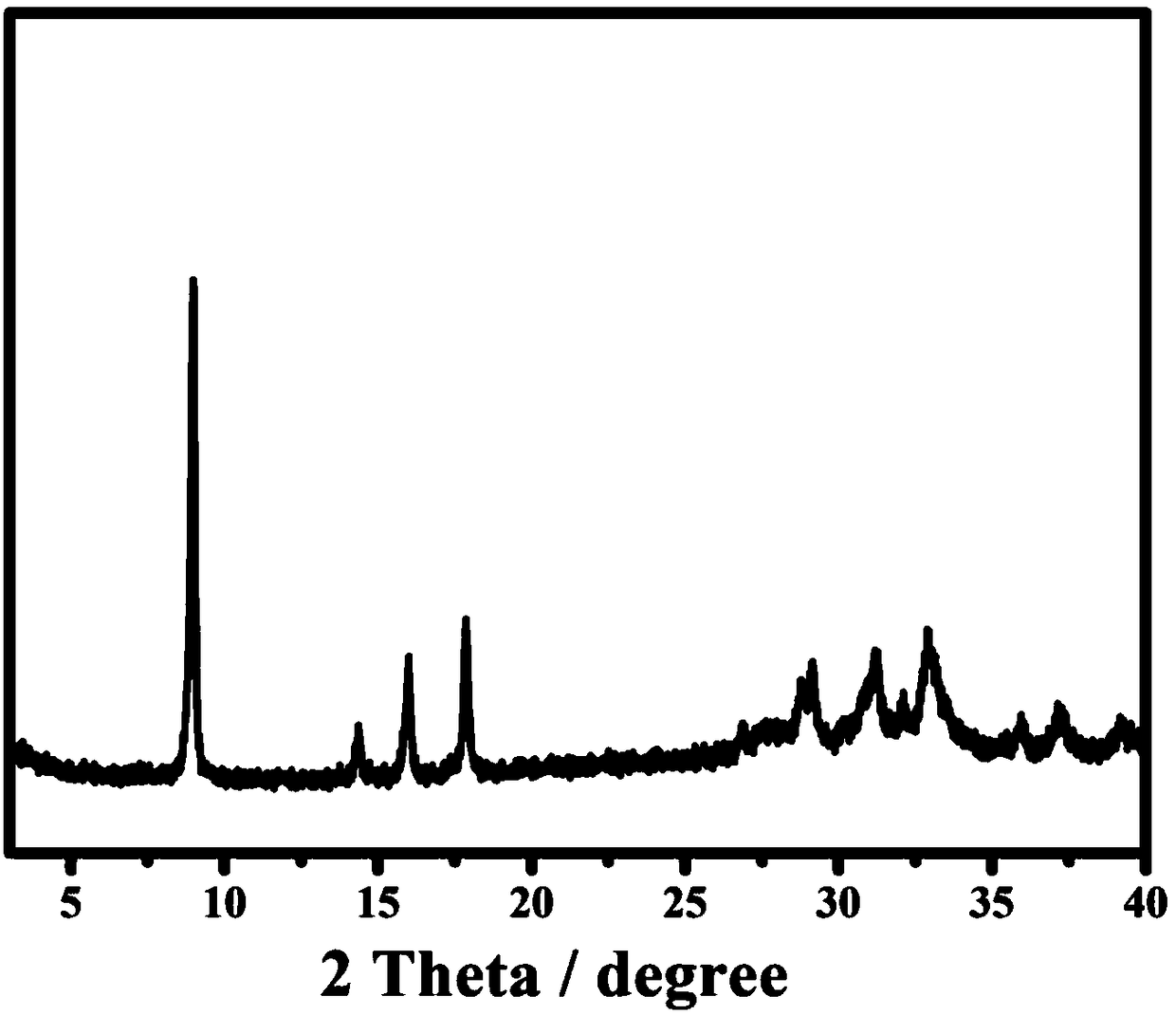

[0022] Step 1: Dissolve 15 mg of palladium chloride and 77 mg of polyvinylpyrrolidone in a mixture of 85 mL of methanol and 15 mL of deionized water, and reflux at 70°C for 4 hours to obtain a Pd nanoparticle solution.

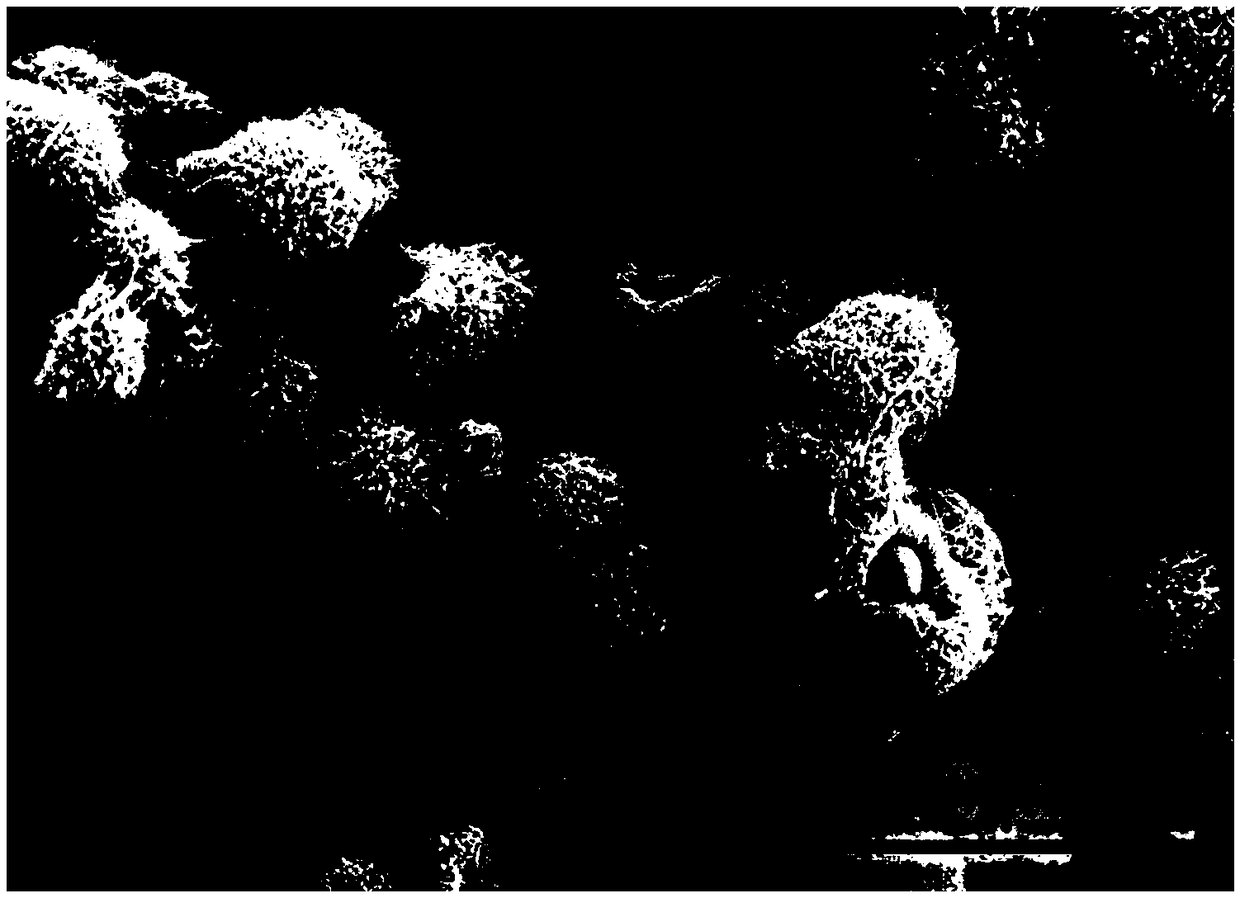

[0023] The second step: Weigh 30mg of terephthalic acid, 60mg of nickel nitrate and 40mg of zinc nitrate and dissolve them in a mixed solution of N,N-dimethylformamide (8mL) and ethylene glycol (5mL), after stirring for 1 hour, Transfer to a polytetrafluoroethylene reactor at a reaction temperature of 150°C. After reacting for 1.5 hours, add the Pd nanoparticle solution (3.5 mL) synthesized above, and react for 4 hours. Then cool, centrifuge, wash, activate, and dry to prepare Pd@Ni / Zn-MOF, noble metal Pd nanoparticles were successfully loaded in the cavity (mainly in the cavity) between the core-shell structure of the core-shell Ni / Zn-MOF.

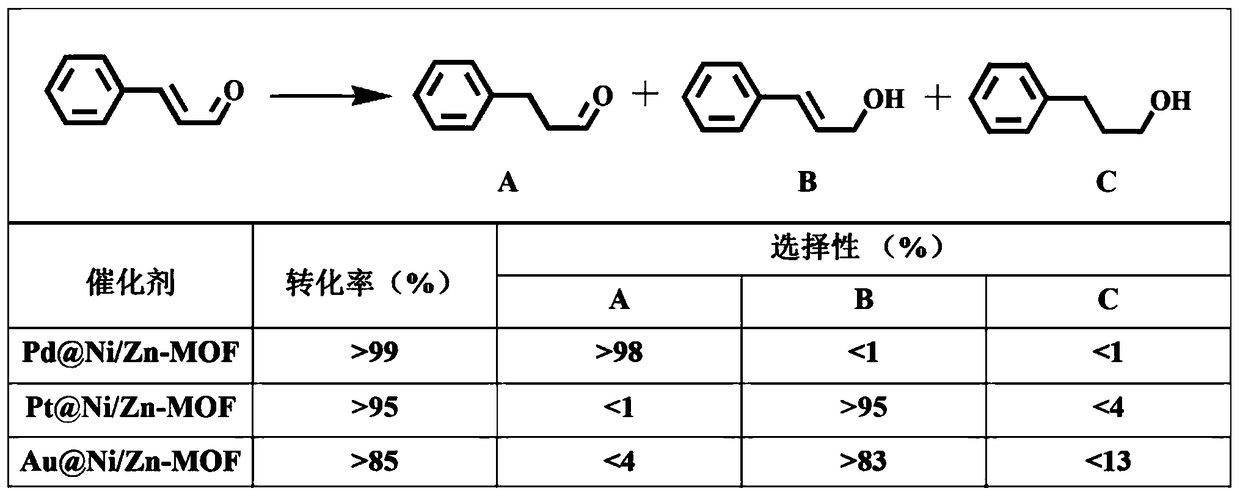

[0024] Step 3: Weigh 20mg of catalyst Pd@Ni / Zn-MOF, 5mL of isopropanol, 0.5mmol of cinnamaldehyde, transfer to a high-p...

Embodiment 2

[0026] The first step: Weigh 16.6mg of polyvinylpyrrolidone and dissolve it in 45mL of ethanol, add 5.0mL of H 2 PtCl 6 (6.0mM) aqueous solution, condensed and refluxed for 3h to obtain a Pt nanoparticle solution.

[0027] The second step: Weigh 30mg of terephthalic acid, 50mg of nickel nitrate and 50mg of zinc nitrate and dissolve them in a mixed solution of N,N-dimethylformamide (10mL) and ethylene glycol (5mL), after stirring for 1 hour, Transfer to a polytetrafluoroethylene reactor, add the Pt nanoparticle solution (5mL) synthesized above, the reaction temperature is 140°C, the reaction time is 6 hours, then cooled, centrifuged, washed, activated, and dried to prepare Pt@Ni / Zn- MOF, noble metal Pd nanoparticles were successfully supported in the core (mainly in the core) of the core-shell structure Ni / Zn-MOF.

[0028] Step 3: Weigh 50mg of catalyst Pt@Ni / Zn-MOF, 5mL of isopropanol, 0.4mmol of cinnamaldehyde, transfer to a high-pressure reactor, feed hydrogen at 1.0MPa, s...

Embodiment 3

[0030] Step 1: Weigh 100mL of HAuCl 4 (0.01%) aqueous solution, condensation reflux, add the aqueous solution of sodium citrate (1%) of 4.5mL, after condensation reflux 20 minutes, drop to room temperature, add 20mL polyvinylpyrrolidone (0.5g) aqueous solution, stir 24 hours at room temperature, Au nanoparticle solution was obtained.

[0031] The second step: Weigh 30mg of terephthalic acid, 60mg of nickel nitrate and 40mg of zinc nitrate and dissolve them in a mixed solution of N,N-dimethylformamide (8mL) and ethylene glycol (5mL), after stirring for 1 hour, Transfer to a polytetrafluoroethylene reactor at a reaction temperature of 150°C. After 6 hours of reaction, add the Au nanoparticle solution (3.5 mL) synthesized above, stir at room temperature, and then centrifugally wash, activate, and dry to prepare Au@ Ni / Zn-MOF, noble metal Pd nanoparticles were successfully loaded outside the shell (mainly outside the shell) of the core-shell structure Ni / Zn-MOF.

[0032] Step 3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com