Environment-friendly type painting door

An environment-friendly, paint-baked door technology, which is applied in the door leaf, pretreatment of molding materials, household components, etc., can solve the problems of no obvious enhancement of the internal structural strength of wooden doors, unsatisfactory fireproof and sound insulation effects, poor wear resistance and pressure resistance, etc. , achieve the effect of shortening the curing time, promoting the chemical reaction speed and good initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

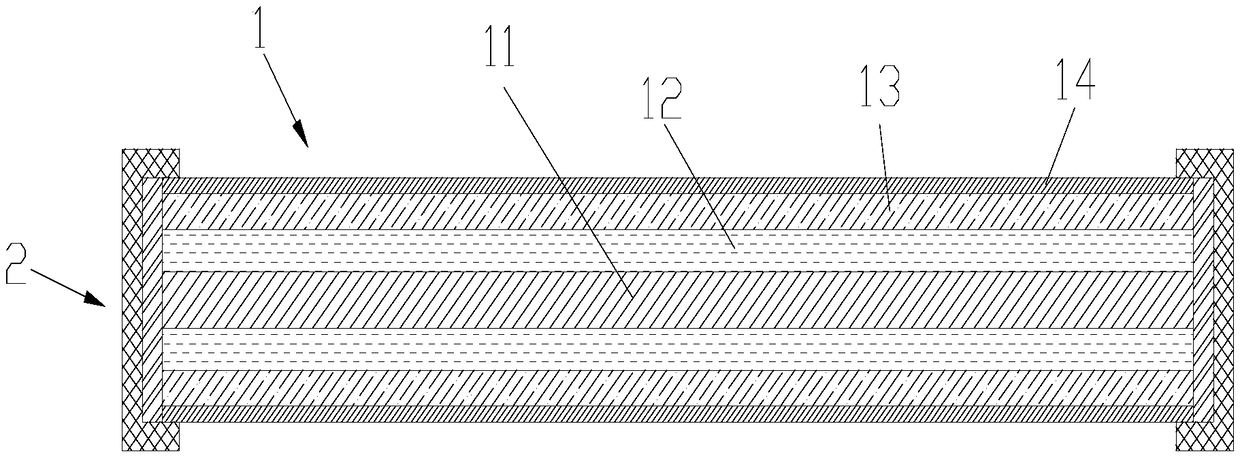

[0036] An environmentally friendly paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a frame 2 arranged on the side of the paint-baking door body 1 for protecting the paint-baking door body 1; The rubber pad 12 that is fixed with the central layer 11 and is used to buffer the impact force of the paint door body 1, and the particle board 13 that is arranged on the surface of the rubber pad 12 and fixed with the rubber pad 12, and the particle board 13 that is arranged on the surface of the particle board 13 , and fixed with the particle board 13, is used for protecting and decorating the tempered glass 14 of the main body 1 of the baking varnish door.

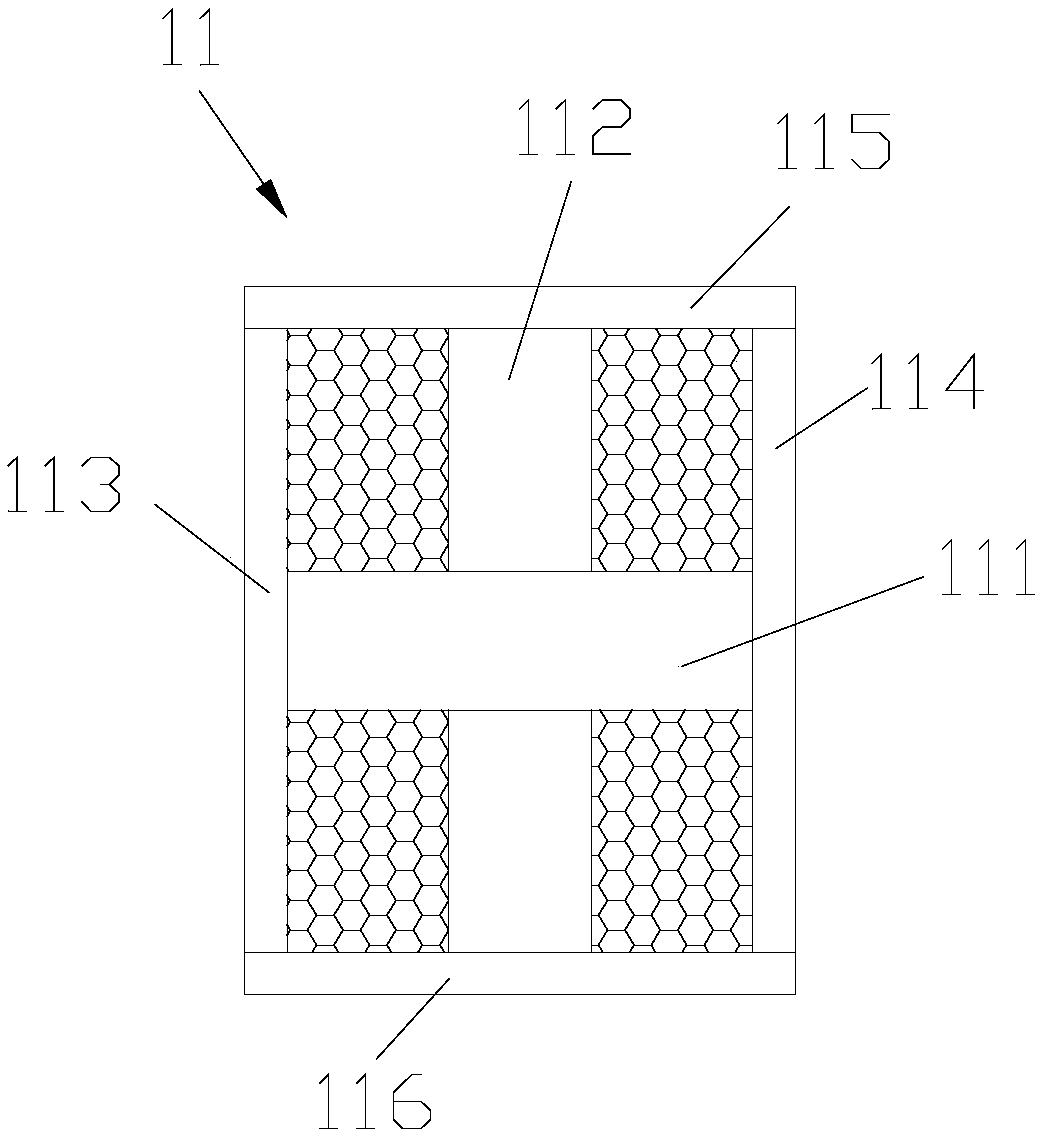

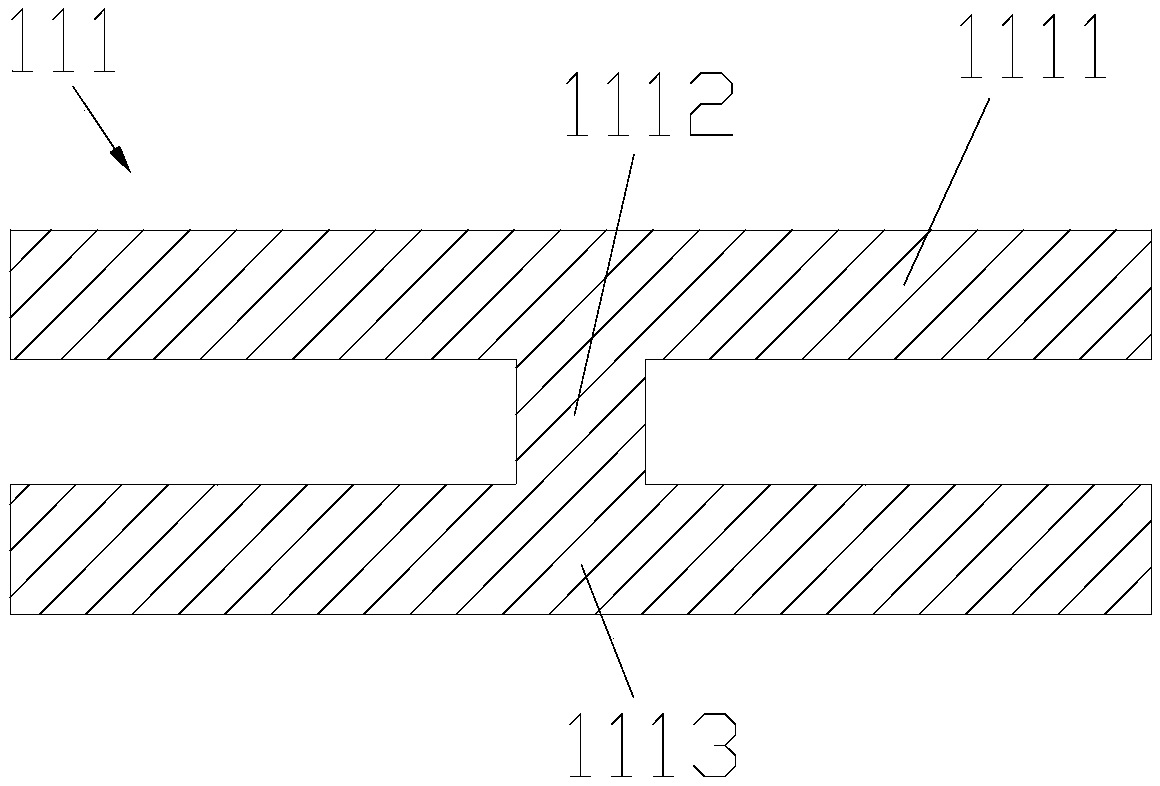

[0037] Such as figure 2As shown, the central layer 11 includes a first center frame bar 111 arranged horizontally, a second center frame bar 112 vertically arranged through the middle of the first center frame bar 111 and perpendicular to it, and arranged on the first center frame bar 112. The...

Embodiment 2

[0053] An environmentally friendly paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a frame 2 arranged on the side of the paint-baking door body 1 for protecting the paint-baking door body 1; The rubber pad 12 that is fixed with the central layer 11 and is used to buffer the impact force of the paint door body 1, and the particle board 13 that is arranged on the surface of the rubber pad 12 and fixed with the rubber pad 12, and the particle board 13 that is arranged on the surface of the particle board 13 , and fixed with the particle board 13, is used for protecting and decorating the tempered glass 14 of the main body 1 of the baking varnish door.

[0054] Such as figure 2 As shown, the central layer 11 includes a first center frame bar 111 arranged horizontally, a second center frame bar 112 vertically arranged through the middle of the first center frame bar 111 and perpendicular to it, and arranged on the first center frame bar 112. Th...

Embodiment 3

[0070] An environmentally friendly paint door, such as figure 1 As shown, it includes a paint-baking door body 1, and a frame 2 arranged on the side of the paint-baking door body 1 for protecting the paint-baking door body 1; The rubber pad 12 that is fixed with the central layer 11 and is used to buffer the impact force of the paint door body 1, and the particle board 13 that is arranged on the surface of the rubber pad 12 and fixed with the rubber pad 12, and the particle board 13 that is arranged on the surface of the particle board 13 , and fixed with the particle board 13, is used for protecting and decorating the tempered glass 14 of the main body 1 of the baking varnish door.

[0071] Such as figure 2 As shown, the central layer 11 includes a first center frame bar 111 arranged horizontally, a second center frame bar 112 vertically arranged through the middle of the first center frame bar 111 and perpendicular to it, and arranged on the first center frame bar 112. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com