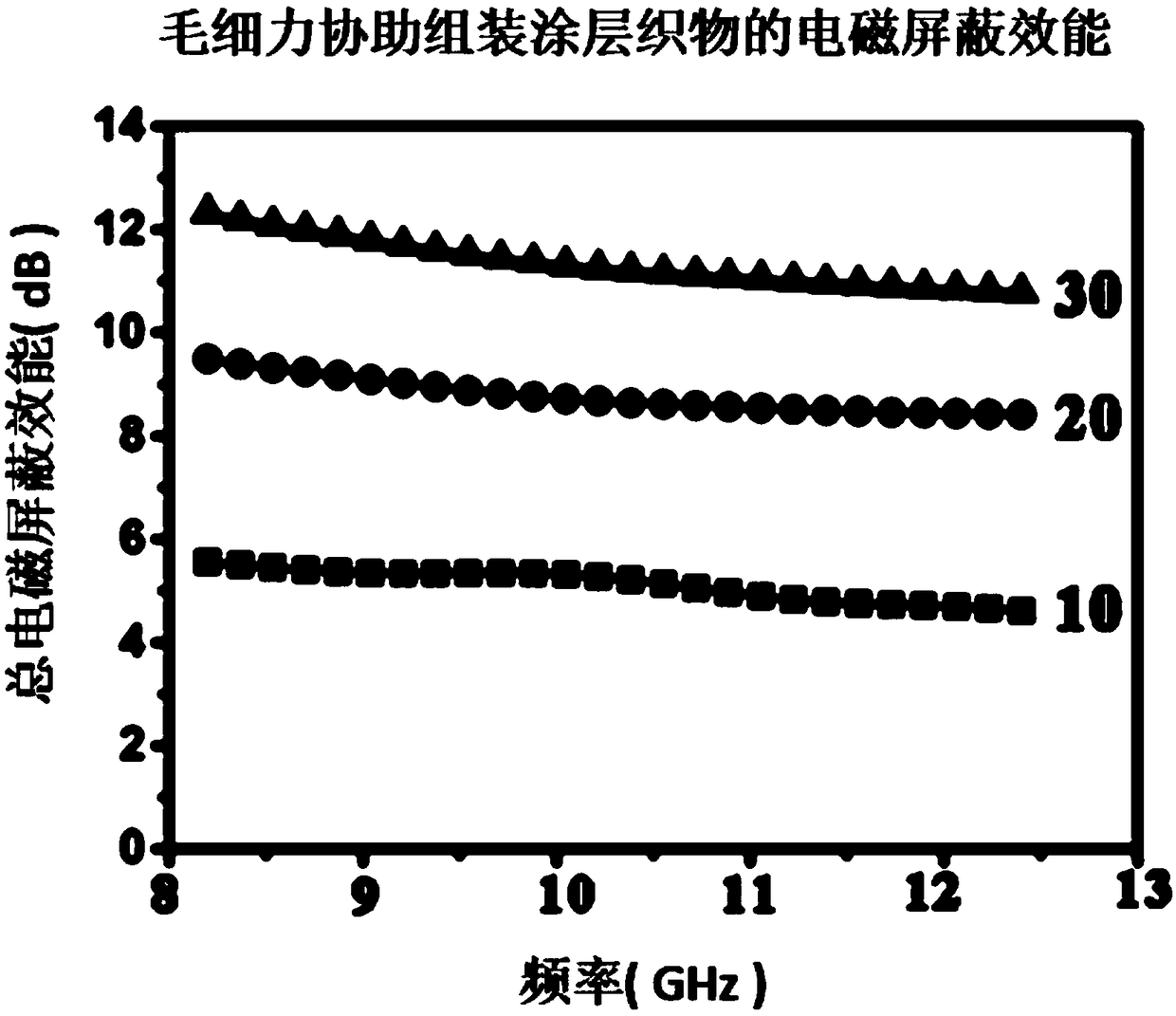

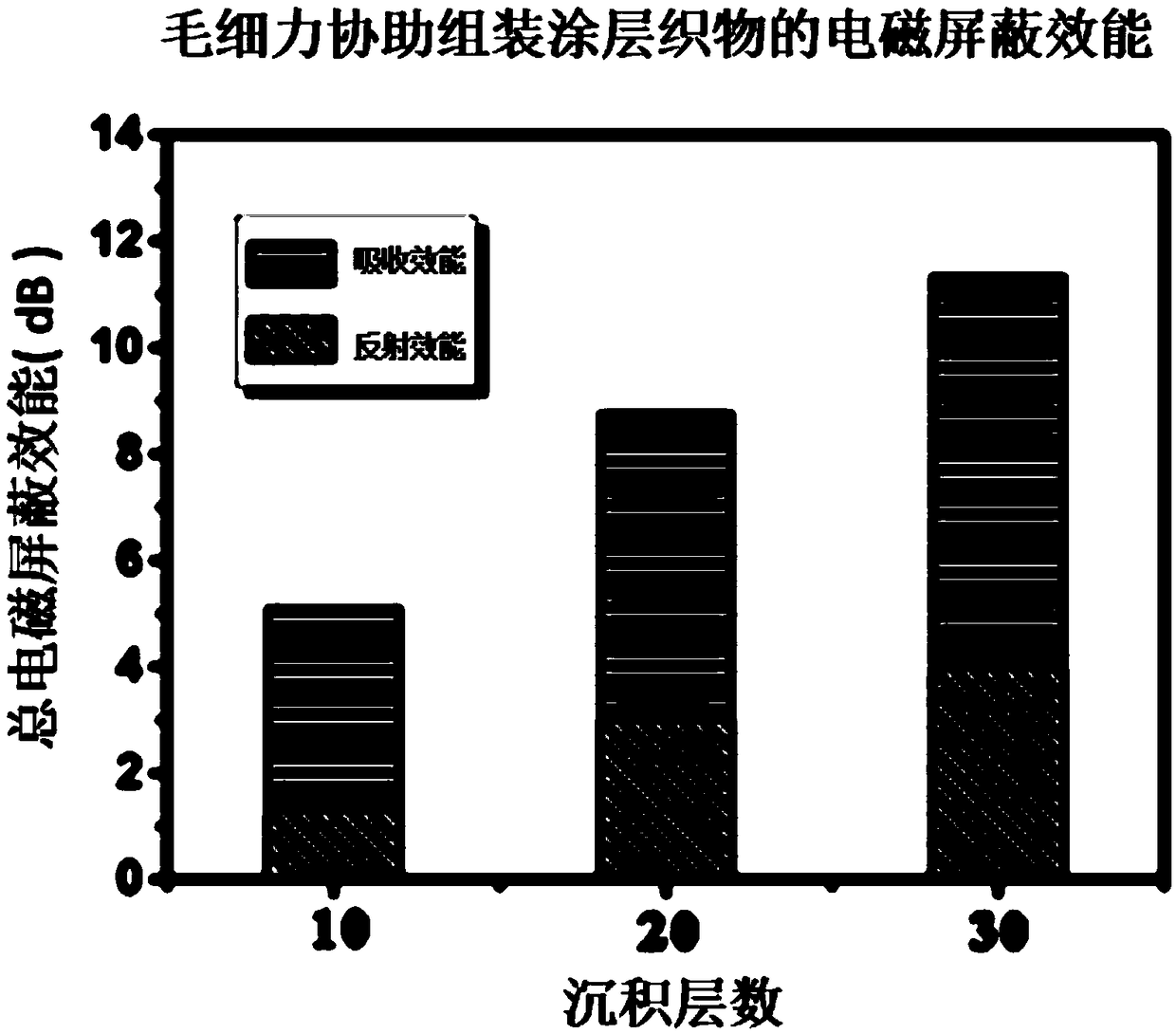

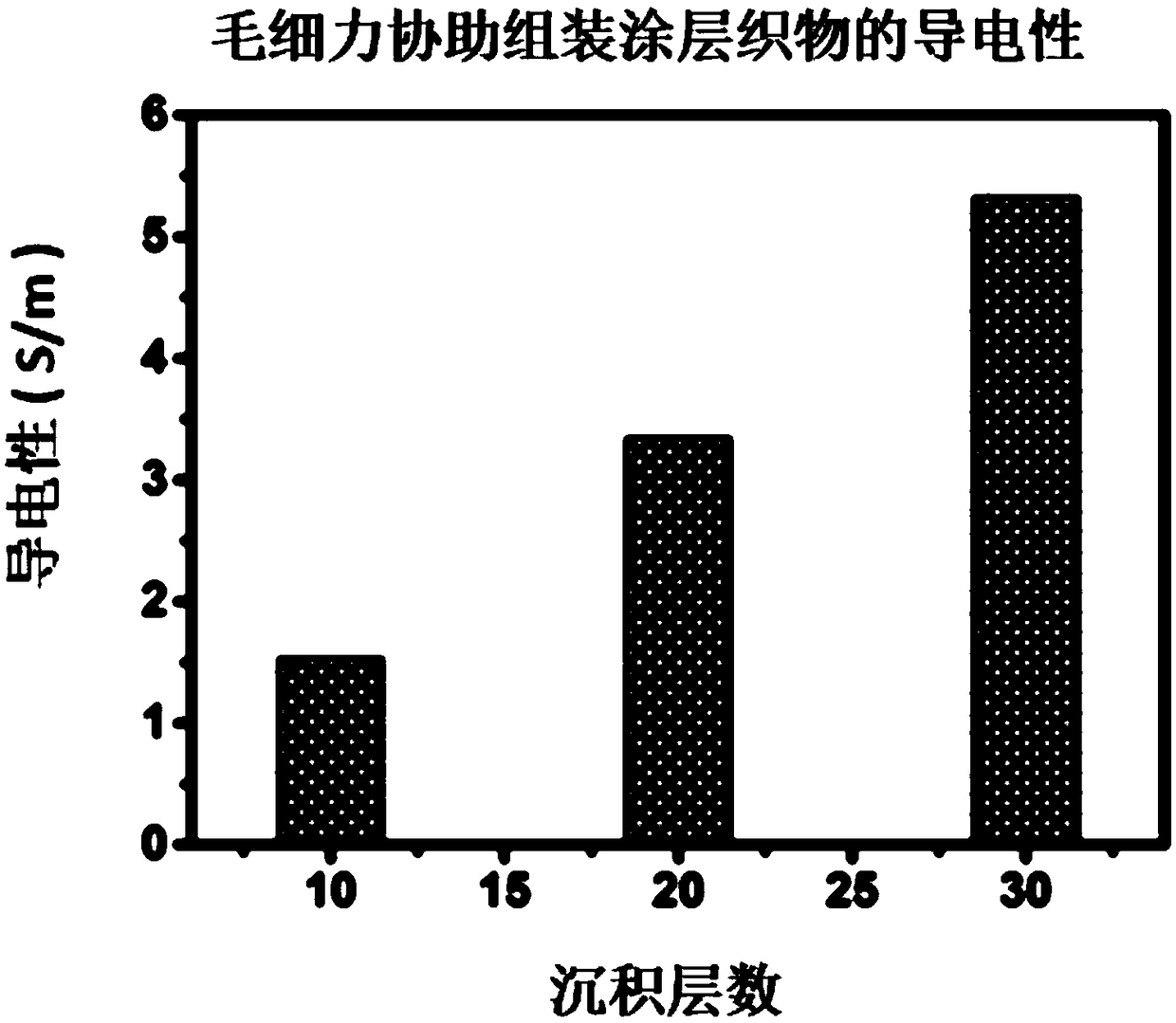

Capillary effect assisted non-covalent assembled coating layer and preparation method thereof

A capillary effect, non-covalent technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor assembly coating functions, etc., and achieve the effects of low production cost, simple preparation method, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Pretreat the non-woven cotton fabric to make it positively charged. The specific pretreatment steps are as follows:

[0036] Soak the non-woven cotton fabric in ethanol solution, and wash it with ultrasonic vibration for 10 minutes, then soak the non-woven cotton fabric with deionized water, and wash it with ultrasonic vibration for 10 minutes. After drying, the fabric was immersed in a mixed solution of 50g / L 3-chloro-2-hydroxypropyltrimethylammonium chloride and 18g / L sodium hydroxide at room temperature for 24 hours, passed through 3-chloro The ring-opening polymerization of -2-hydroxypropyltrimethylammonium chloride generates 2,3-epoxypropyltrimethylammonium chloride (C.Yilmaz, A.Sirman, A.Halder, A. Busnaina, ACS nano 2017, 11, 7679., it reacts with the hydroxyl group of the cotton fabric to provide rich positive charges on the surface of the fabric. After the treatment, soak the cotton fabric with deionized water, and finally put the fabric in a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com