Synchronous recycling and purifying method for oil in oily sludge

A technology of oil and sludge, which is applied in the field of synchronous recovery and purification of oil in oily sludge, can solve the problems of poor treatment effect, high energy consumption, and high treatment cost of high-viscosity oily sludge, and achieve good oil-water separation and contact area The effect of increasing, increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

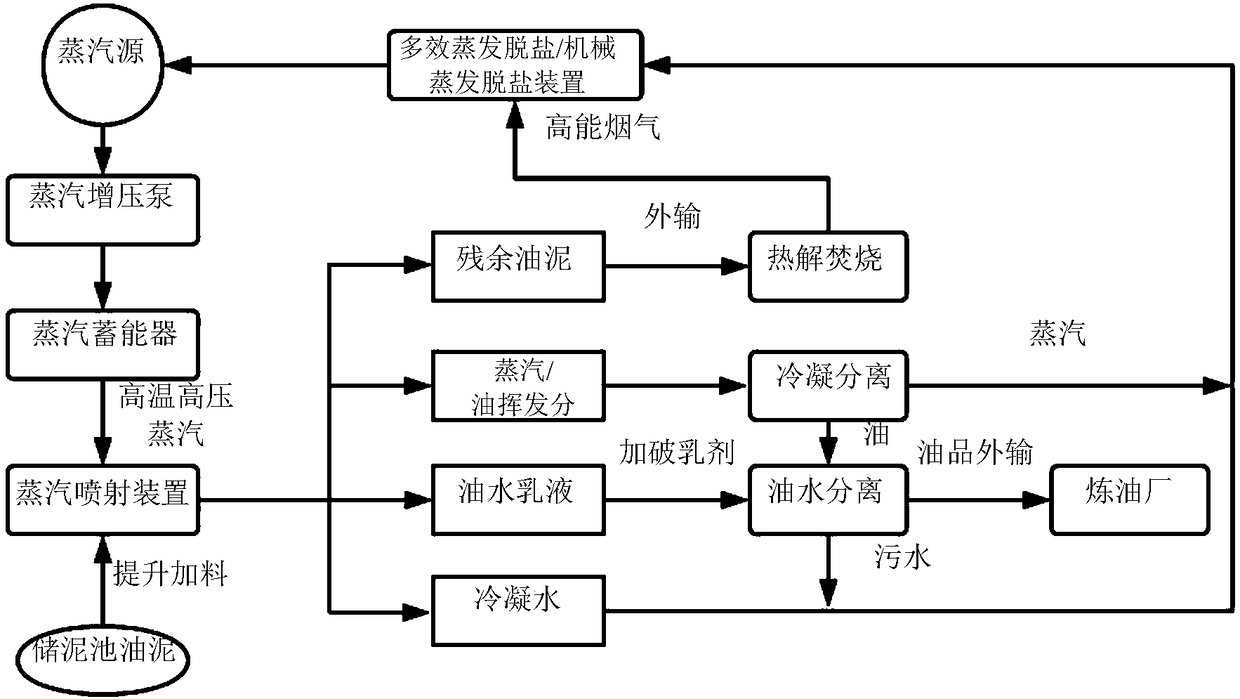

[0023] according to figure 1 The process uses high-viscosity oily sludge as raw material, uses a grab crane to dig up the sludge and transports it to the screw feeder, and the screw feeder transports it to the steam injection box with a feeding rate of 0.5 tons / hour. After the steam is heated and pressure adjusted, the temperature reaches 300°C, the pressure reaches 8MPa, and the steam injection rate is 3 tons / hour. The temperature inside the steam injection box reached 97°C within 20 seconds. Control the residence time of the floating oil layer to be 5 minutes. The oil scraper scrapes off the floating oil layer, and then performs demulsification and cyclone dehydration. The application amount of the thick oil demulsifier is 2g / L. In this embodiment, the oil recovery rate is 0.22 tons / hour, and the sludge residue discharge rate is 0.25 tons / hour. The total metal impurity content of recovered oil was reduced by 82%, among which Fe and Zn were reduced by 41% and 17% respectiv...

Embodiment 2

[0025] according to figure 1 The process uses high-viscosity oily sludge as raw material, uses a grab crane to dig up the sludge and transports it to the screw feeder, and the screw feeder transports it to the steam injection box, and the feeding rate is 1 ton / hour. After the steam is heated and pressure adjusted, the temperature reaches 350°C, the pressure reaches 16MPa, and the steam injection rate is 6 tons / hour. The temperature inside the steam injection box reaches 98°C within 15 seconds. Control the residence time of the floating oil layer to be 3 minutes. The oil scraper scrapes off the floating oil layer, and then performs demulsification and cyclone dehydration. The application amount of the thick oil demulsifier is 2g / L. In this embodiment, the oil recovery rate is 0.46 tons / hour, and the sludge residue discharge rate is 0.5 tons / hour. The total metal impurity content of recovered oil is reduced by 78%, among which Fe and Zn are reduced by 26% and 17% respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com