Method for synthesizing glycine by performing alkaline hydrolysis on aminoacetonitrile continuously and rapidly

A technology of aminoacetonitrile and glycine, applied in chemical instruments and methods, preparation of organic compounds, chemical/physical/physicochemical processes, etc., can solve the problems of slow reaction rate, easy production of by-products, easy decomposition of raw materials, etc., to reduce The effect of production cost, reduction of pyrolysis polymerization and by-product formation, and shortening of alkaline hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

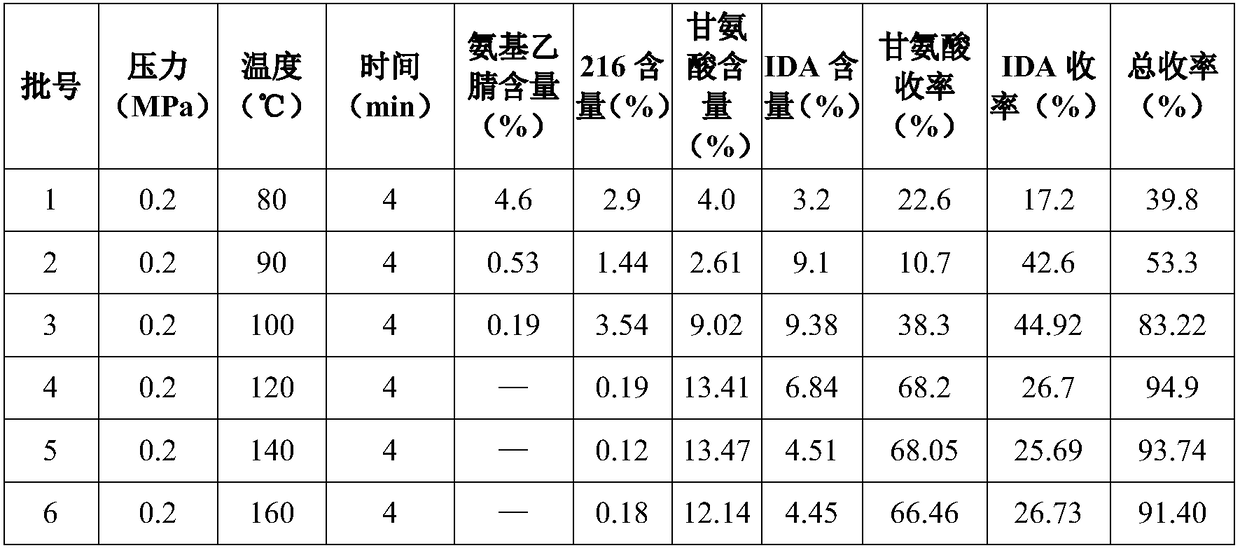

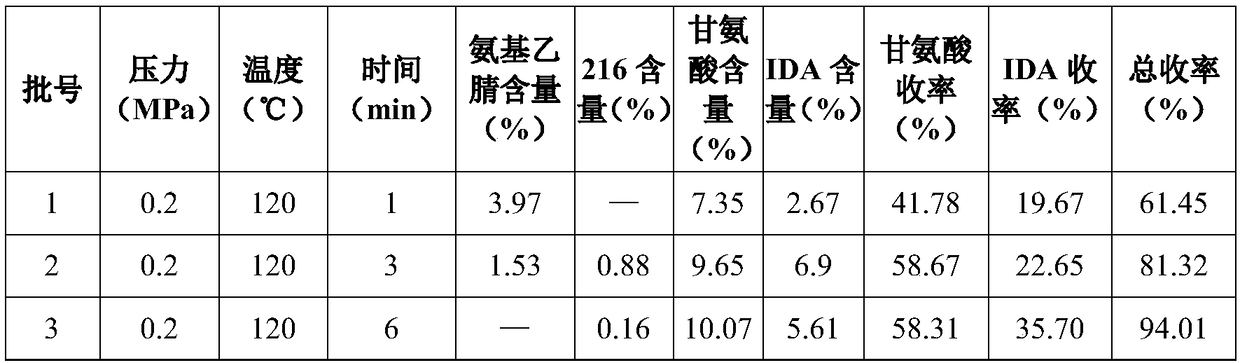

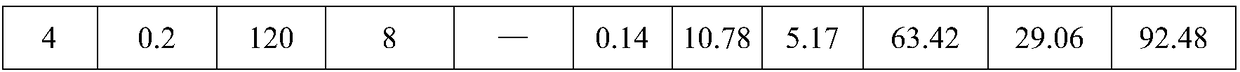

Embodiment 1

[0025] Mix hydroxyacetonitrile with excess ammonia solution (by molar amount, hydroxyacetonitrile:ammonia=1:2) to obtain an ammonia solution containing aminoacetonitrile, and simultaneously pump the sodium hydroxide aqueous solution and the ammonia solution containing aminoacetonitrile into the micro In the channel reactor, the flow rate of sodium hydroxide aqueous solution in the microchannel is 1.56ml / min, and the flow rate of the ammonia solution containing aminoacetonitrile in the microchannel is 5.44ml / min, that is, the mol ratio of hydroxyacetonitrile and sodium hydroxide is 1:1.1, control the reaction temperature to 120°C, the pressure to 0.2MPa, and the residence time to be 4min (that is, the alkaline hydrolysis time, which is also the time for the reaction solution to flow through the microchannel), and neutralize the obtained alkaline solution with sulfuric acid after deamination When pH=2, the obtained neutralizing solution is decolorized by adding activated carbon, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com