Automatic earthworm biological-composting sludge disposal system and application method thereof

A sludge disposal and earthworm technology, applied in the field of automatic earthworm biological composting sludge disposal system, can solve the problems of secondary pollution, reduced production efficiency, uncontrollable secondary treatment, etc., and achieves the goal of ensuring safety and saving land use area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

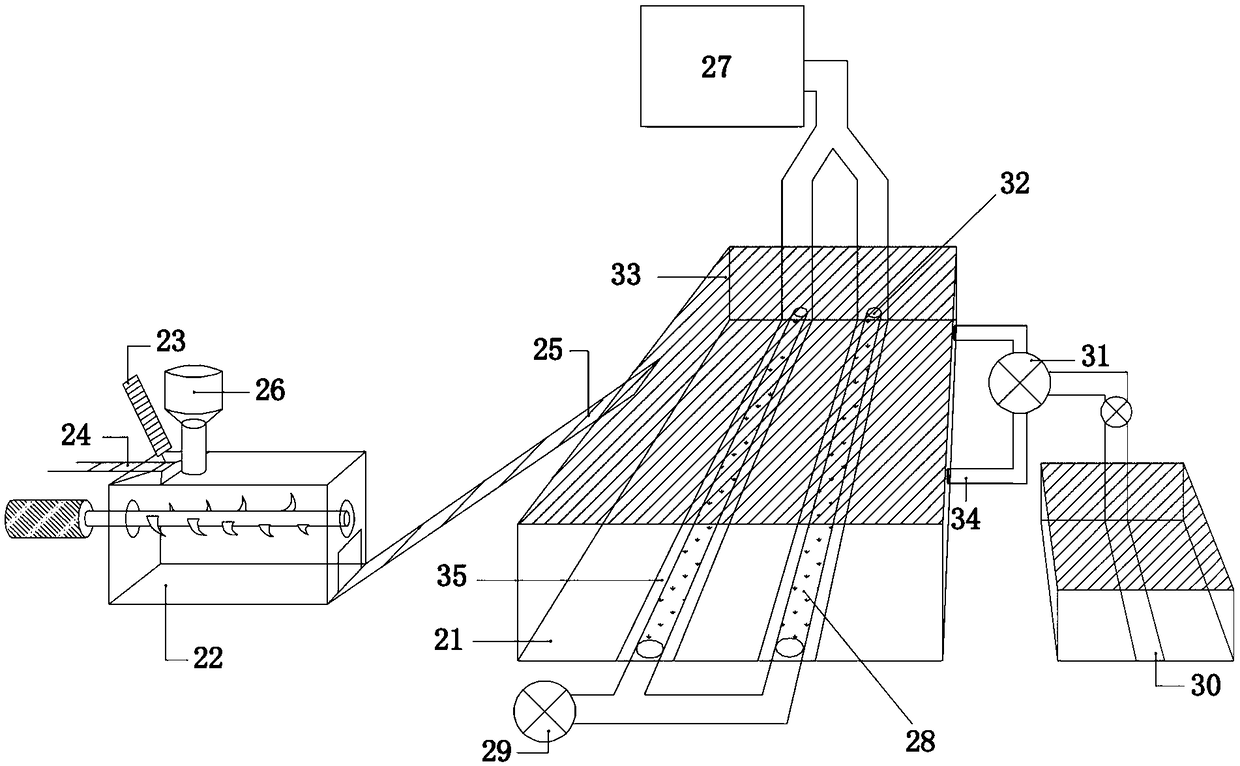

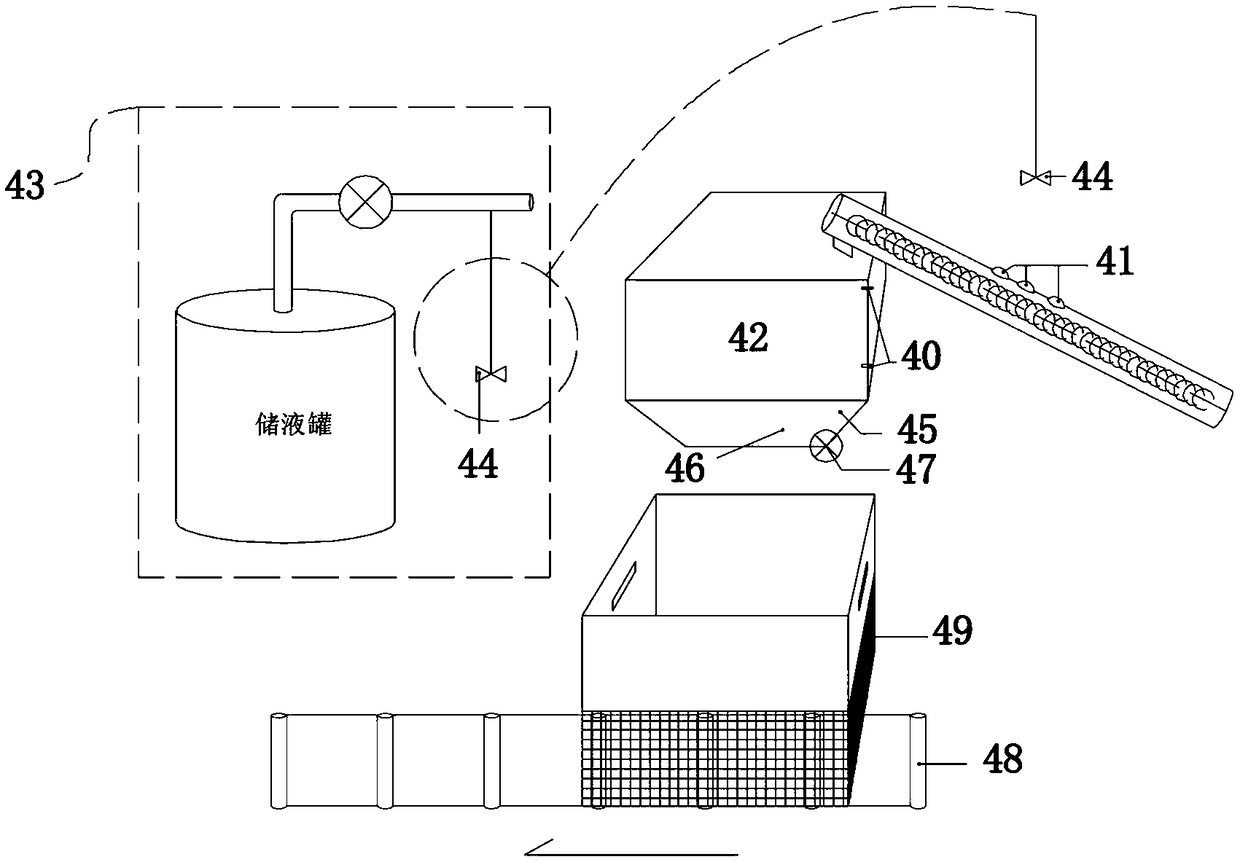

[0063] An automatic earthworm biocomposting sludge disposal system, including a bioleaching pretreatment system, a static decomposing pretreatment system, an automatic feeding system, a modular composting system, and an automatic sieve collection system for earthworms / worm cocoons;

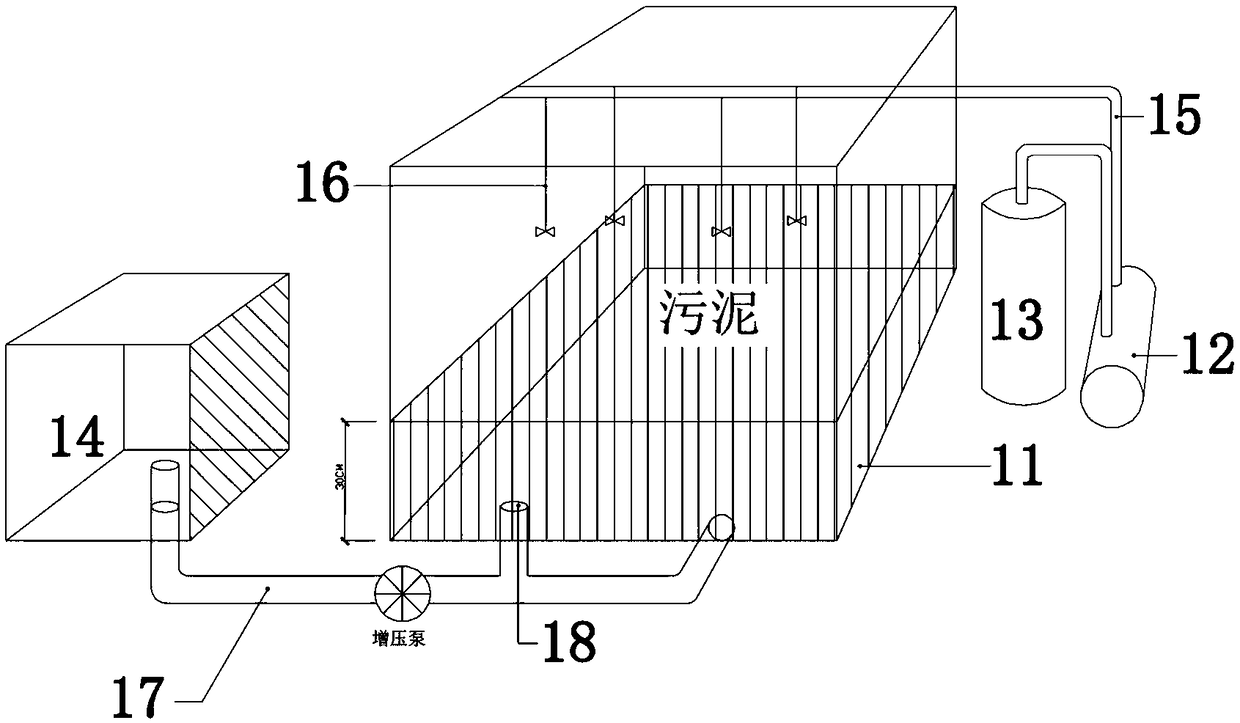

[0064] Such as figure 1 As shown, the bioleaching pretreatment system includes: a pretreatment tank 11, a centrifugal pump 12, a liquid storage tank 13, a sewage treatment device A14, a small tube 15, a nozzle A16 and a sewage pipeline 17, and a time-controlled switch;

[0065] The pretreatment pool 11 adopts a brick-concrete structure, and anti-seepage treatment is carried out on the inner wall surface, and is used for placing sludge; above the pretreatment pool 11, a sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com