A treatment process for high-concentration refractory sewage

A kind of treatment process, refractory technology, applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment and other directions, can solve the problems of high cost and unsuitable for large-scale sewage treatment, to reduce the dosage, promote The formation of hydroxyl radicals and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

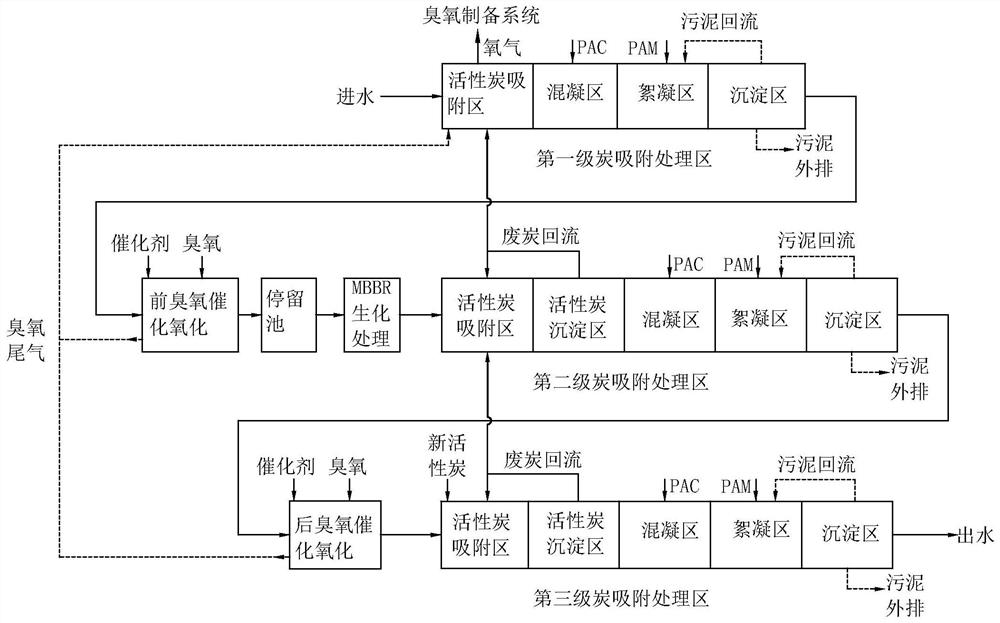

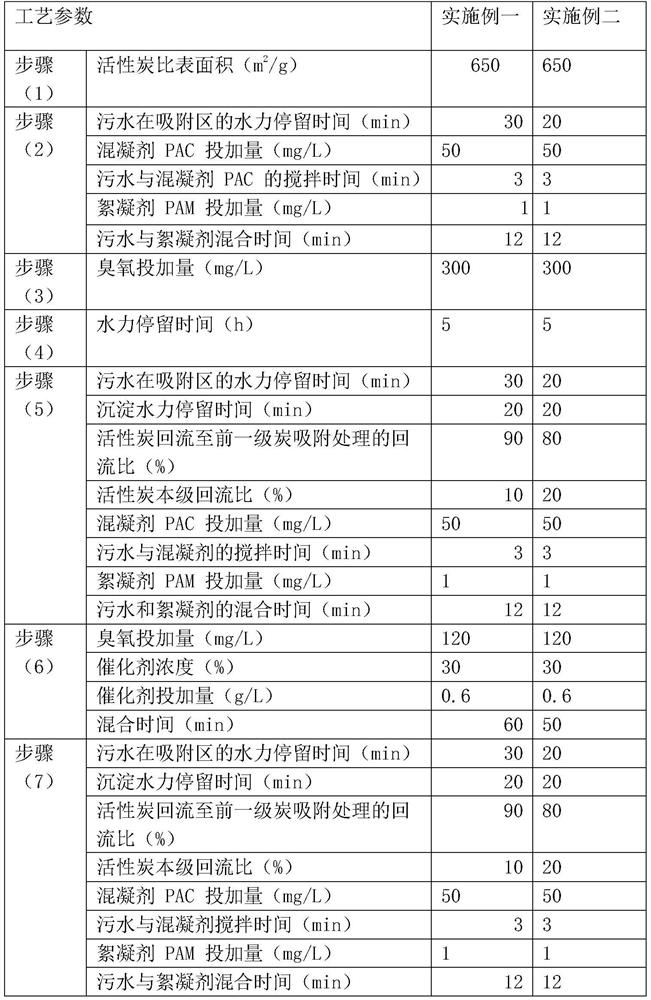

[0033] Embodiment 1: a kind of treatment process of high-concentration refractory sewage, combined with figure 1 , including sequentially connected first-stage carbon adsorption area, pre-ozone catalytic oxidation, MBBR biochemical treatment, second-stage carbon adsorption treatment area, post-ozone catalytic oxidation and third-stage carbon adsorption treatment area.

[0034] The first-stage carbon adsorption treatment area includes successively connected activated carbon adsorption area, coagulation area, flocculation area and precipitation area; the second-level carbon adsorption treatment area and the third-level carbon adsorption treatment area both include activated carbon adsorption area, activated carbon precipitation area, Coagulation zone, flocculation zone and sedimentation zone.

[0035] The above process was used to treat the anammox effluent of a sewage treatment plant. The water quality of the sewage is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com