A large-scale large-scale continuous production of graphene method, device and graphene prepared therefrom

A graphene and few-layer graphene technology, applied in the field of graphene, can solve the problem of batch preparation of high-quality graphene that is difficult to achieve environmental protection, fast, efficient, and low-cost, has no practical application value, and has poor peeling effect by ball milling. problem, to achieve the effect of excellent physical and chemical properties, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

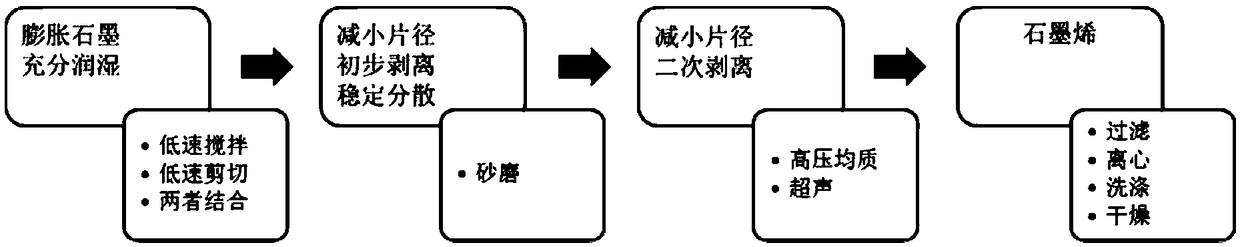

Method used

Image

Examples

Embodiment 1

[0083] Step 1: Fully wet the expanded graphite in the solvent and reduce the sheet diameter by stirring at a low speed. The expanded graphite is prepared by high temperature expansion method, the expansion ratio is 150, the solvent is NMP, and the expanded graphite is in the mixture of expanded graphite and solvent. The concentration in the mixture is 0.1wt%, and the stirring time is 0.2h to obtain the expanded graphite dispersion.

[0084] Step 2: The fully wetted expanded graphite dispersion in step 1 is further reduced in diameter by sand milling to obtain a uniform and stable initially exfoliated coarse graphene dispersion. Sanding time is 0.5h.

[0085] Step 3: The stable preliminary exfoliated coarse graphene dispersion in step 2 is subjected to high-pressure homogenization to obtain a single-layer or few-layer graphene dispersion. The pressure of high pressure homogenization is 30MPa, and the time is 1h.

[0086] Step 4: The single-layer or few-layer graphene dispersi...

Embodiment 2

[0088] Step 1: Fully wet the expanded graphite in the solvent and reduce the sheet diameter by means of low-speed shearing. The expanded graphite is prepared by a high-temperature expansion method with an expansion ratio of 250. The solvent is acetone. The expanded graphite is mixed with the expanded graphite and the solvent. The concentration in the mixture is 2.5 wt%, and the stirring time is 1 h to obtain the expanded graphite dispersion.

[0089] Step 2: The fully wetted expanded graphite dispersion in step 1 is further reduced in diameter by sand milling to obtain a uniform and stable initially exfoliated coarse graphene dispersion. Sanding time is 1h.

[0090] Step 3: The stable preliminary exfoliated coarse graphene dispersion in step 2 is subjected to high-pressure homogenization to obtain a single-layer or few-layer graphene dispersion. The pressure of high pressure homogenization is 65MPa, and the time is 2h.

[0091] Step 4: The single-layer or few-layer graphene ...

Embodiment 3

[0093] Step 1: Through low-speed stirring combined with low-speed shearing, the expanded graphite is fully wetted in the solvent and the sheet diameter is reduced. The expanded graphite is prepared by microwave expansion method, the expansion ratio is 300, the solvent is ethanol, and the expanded graphite is prepared in the expanded graphite The concentration in the mixture with the solvent is 5wt%, and the stirring time is 2h to obtain the expanded graphite dispersion.

[0094] Step 2: The fully wetted expanded graphite dispersion in step 1 is further reduced in diameter by sand milling to obtain a uniform and stable initially exfoliated coarse graphene dispersion. Sanding time is 3h.

[0095] Step 3: ultrasonically treating the stable and initially exfoliated coarse graphene dispersion in step 2 to obtain a single-layer or few-layer graphene dispersion. Time 3h.

[0096] Step 4: The single-layer or few-layer graphene dispersion in step 3 is filtered, centrifuged, washed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com