Honeycomb cardboard for packaging

A technology for honeycomb cardboard and packaging, applied to paper/cardboard layered products, layered products, synthetic resin layered products, etc., can solve the problems of non-waterproof and moisture-proof, poor three-dimensional modeling ability, poor puncture resistance, etc., to achieve Save cost, improve service life, save process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further illustrated below in conjunction with specific examples, which are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention.

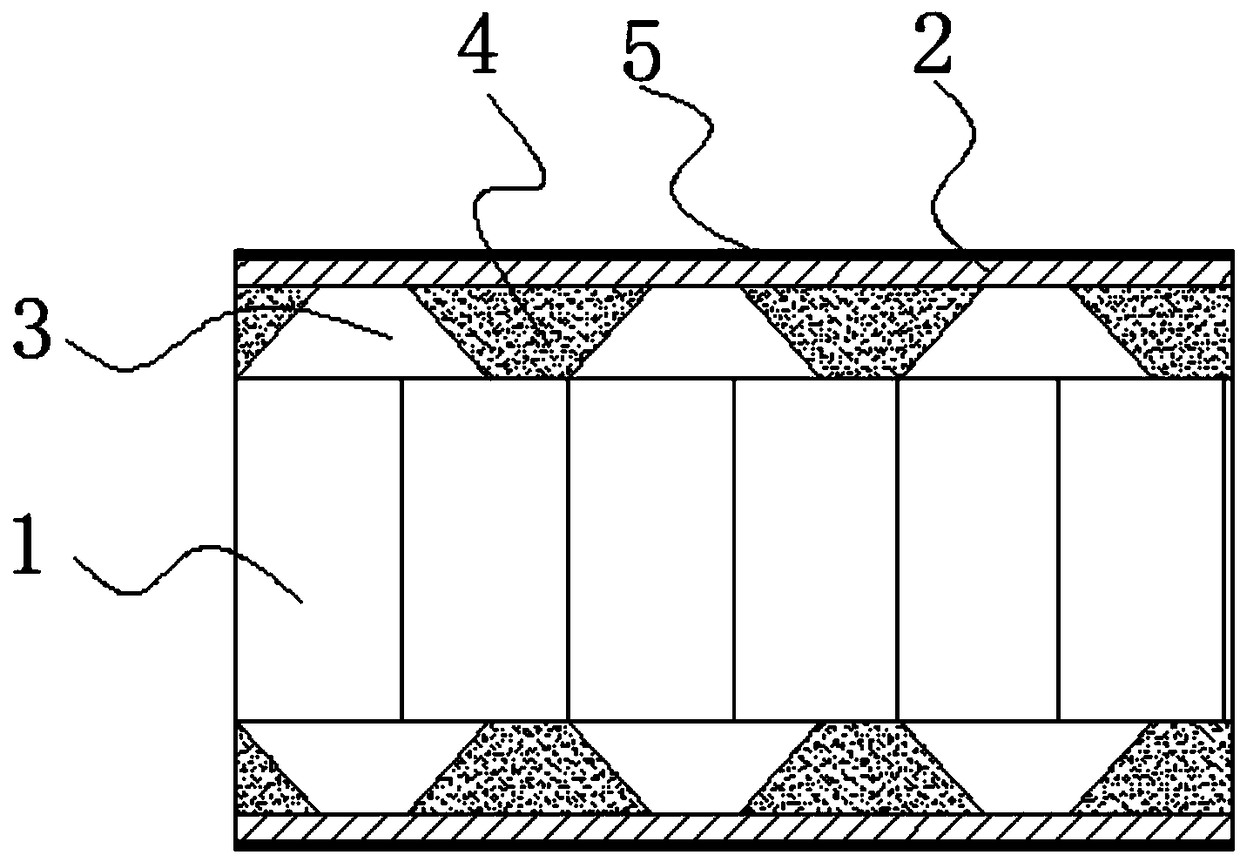

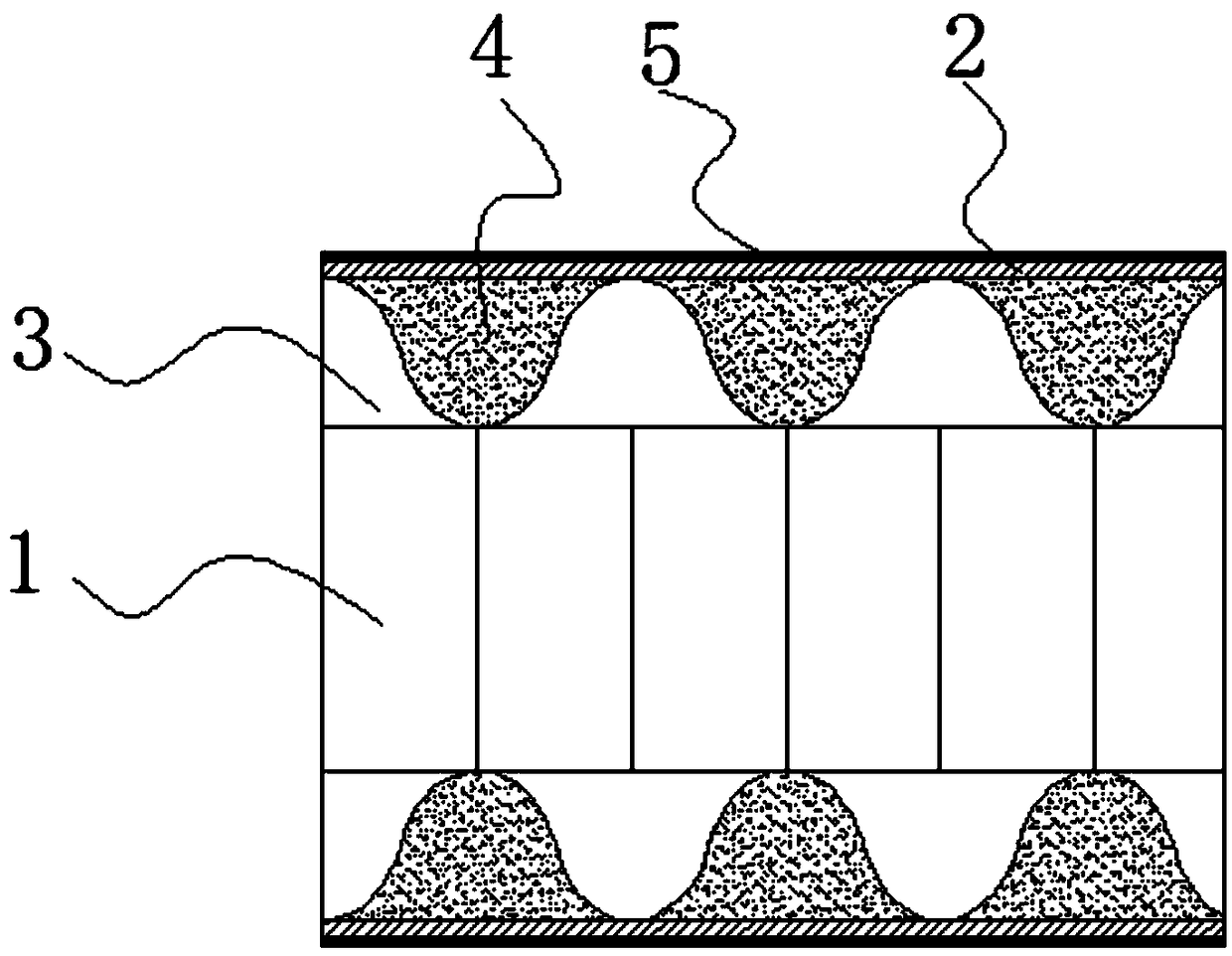

[0017] like Figure 1-3 As shown, a honeycomb paperboard for packaging includes a honeycomb column layer 1, and the cross-sectional shape of the honeycomb column layer is a regular hexagon or a rhombus.

[0018] The honeycomb column layer is provided with a face paper layer 2 up and down, and the face paper layer 2 is selected from corrugated cardboard, kraft cardboard, yellow cardboard, white cardboard or impregnated liner cardboard commonly used in the market.

[0019] A sandwich layer 3 is arranged between the honeycomb column layer 1 and the panel layer 2; the longitudinal section of the sandwich layer 3 is triangular (such as figure 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com