Self-charging lithium-ion batteries based on triboelectric nanogenerators

A lithium-ion battery and nanogenerator technology, applied in battery circuit devices, current collectors, electric vehicles, etc., to achieve long life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

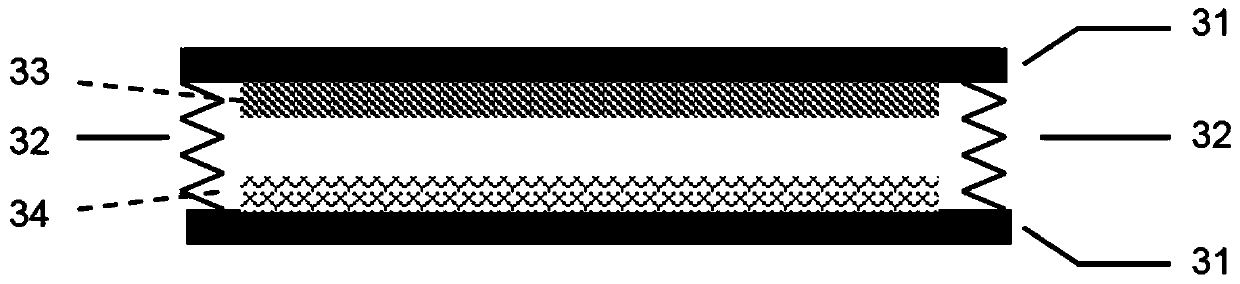

[0057] Cut a long strip of acrylic plate support with a size of 130×18×3mm and a spacer with a size of 18×10×1.2mm, and paste the spacer tightly on both ends of the support, and then make a 100×18 The lithium-ion battery ×0.4mm is centered and tightly pasted on the surface of the support (the positive electrode of the battery faces the pasting surface), and a polyperfluoroethylene film with a size of 130mm×18mm×0.04mm is placed between the upper and lower batteries, and finally the battery is fixed with plastic screws. Fixed at both ends (dual battery type).

[0058] When the friction generator is placed in an environment with a wind speed of 10m / s, the output voltage of the generator is 200V and the current is 25μA.

Embodiment 2

[0060] Cut a long strip of acrylic plate support with a size of 130×18×3mm and a spacer with a size of 18×10×2mm, and paste the spacer tightly on both ends of the support, and then make a size of 100×18× The 0.4mm lithium-ion battery is centered and tightly pasted on the surface of the support (the positive electrode of the battery faces the paste surface), and a polyperfluoroethylene film with a size of 130×18×0.04mm is placed between the upper and lower batteries, and finally the two are connected with plastic screws. Terminal fixed (dual battery type).

[0061] When the friction generator is placed in an environment with a wind speed of 10m / s, the output voltage of the friction generator is 130V and the current is 17μA.

Embodiment 3

[0063] Cut a long strip of acrylic plate support with a size of 130×18×3mm and a spacer with a size of 18×10×1.2mm, and paste the spacer tightly on both ends of the support, and then make a 100×18 A lithium-ion battery of ×0.4mm is centered and tightly pasted on the surface of the support (the positive electrode of the battery faces the pasting surface), and a polyimide film with a size of 130×18×0.04mm is placed between the upper and lower batteries, and finally the plastic screw is used to secure the Fixed at both ends (dual battery type).

[0064] When the friction generator is placed in an environment with a wind speed of 10m / s, the output voltage of the friction generator is 100V and the current is 13μA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com