Nickel cobaltate hollow sphere/carbon nitride quantum dot composite material, preparation method and application thereof

A composite material and hollow sphere technology, applied in the field of electrochemistry, can solve problems such as poor electrocatalytic performance, and achieve the effects of excellent electrochemical catalytic performance, simple preparation method and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

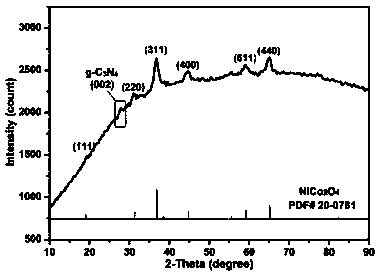

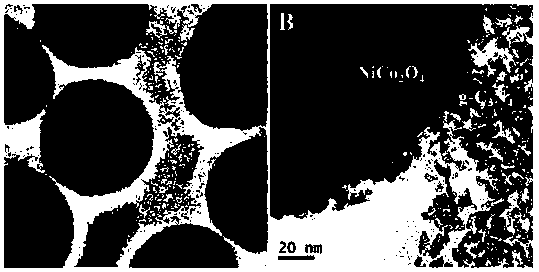

[0038] This embodiment provides a NiCo 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot composite material, the composite electrode material contains NiCo 2 O 4 Hollow ball and g-C 3 N 4 The molar mass ratio of quantum dots is: 1mmol:0.8g, which is prepared by the following preparation method:

[0039] Place 50g of urea in a ceramic crucible, cover it with a lid, and place it in a muffle furnace for heat treatment at 550°C for 2h to obtain a product of g-C 3 N 4 Quantum dot precursor.

[0040] Combine 0.25 mmol nickel nitrate, 0.50 mmol cobalt nitrate and 0.2g g-C 3 N 4 The quantum dot precursor was dissolved and dispersed with 50ml of glycerol and 10ml of ethylene glycol, then added to the hydrothermal reactor, and reacted at a constant temperature at 180°C for 6h, and finally washed, filtered and dried to obtain the product as NiCo 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot hybrid precursors.

[0041] 0.2g NiCo 2 O 4 Hollow ball / g-C 3 N 4 The quantum dot mixed precursor is placed in a ceramic c...

Embodiment 2

[0045] This embodiment provides a NiCo 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot composite material, the composite electrode material contains NiCo 2 O 4 Hollow ball and g-C 3 N 4 The molar mass ratio of quantum dots is: 1mmol:0.8g, which is prepared by the following preparation method:

[0046] Place 50g of urea in a ceramic crucible, cover it with a lid, and place it in a muffle furnace for heat treatment at 550°C for 2h to obtain a product of g-C 3 N 4 Quantum dot precursor.

[0047] Combine 0.25 mmol nickel nitrate, 0.50 mmol cobalt nitrate and 0.2g g-C 3 N 4 The quantum dot precursor was dissolved and dispersed with 50ml of glycerol and 10ml of ethylene glycol, then added to the hydrothermal reactor, and reacted at a constant temperature at 180°C for 6h. Finally, the product was washed, filtered and dried to obtain NiCo. 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot hybrid precursors.

[0048] 0.2g NiCo 2 O 4 Hollow ball / g-C 3 N 4 The quantum dot mixed precursor is placed in a ceramic cr...

Embodiment 3

[0051] This embodiment provides a NiCo 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot composite material, the composite electrode material contains NiCo 2 O 4 Hollow ball and g-C 3 N 4 The molar mass ratio of quantum dots is: 1mmol:0.8g, which is prepared by the following preparation method:

[0052] Place 50g of urea in a ceramic crucible, cover it with a lid, and place it in a muffle furnace for heat treatment at 550°C for 2h to obtain a product of g-C 3 N 4 Quantum dot precursor.

[0053] Combine 0.25 mmol nickel nitrate, 0.50 mmol cobalt nitrate and 0.2g g-C 3 N 4 The quantum dot precursor was dissolved and dispersed with 50ml of glycerol and 10ml of ethylene glycol, then added to the hydrothermal reactor, and reacted at a constant temperature at 180°C for 6h. Finally, the product was washed, filtered and dried to obtain NiCo. 2 O 4 Hollow ball / g-C 3 N 4 Quantum dot hybrid precursors.

[0054] 0.2g NiCo 2 O 4 Hollow ball / g-C 3 N 4 The quantum dot mixed precursor is placed in a ceramic cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com