A mass production method for water-based ion battery pole pieces with porous ceramic structure

An ion battery, porous ceramic technology, applied in battery electrodes, structural parts, electrode manufacturing and other directions, can solve the problems of difficult to meet environmental protection requirements, difficult to control the casting method, easy cracking of ceramic substrates, etc., to achieve safe and reliable equipment operation. The effect of low cost and significant practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

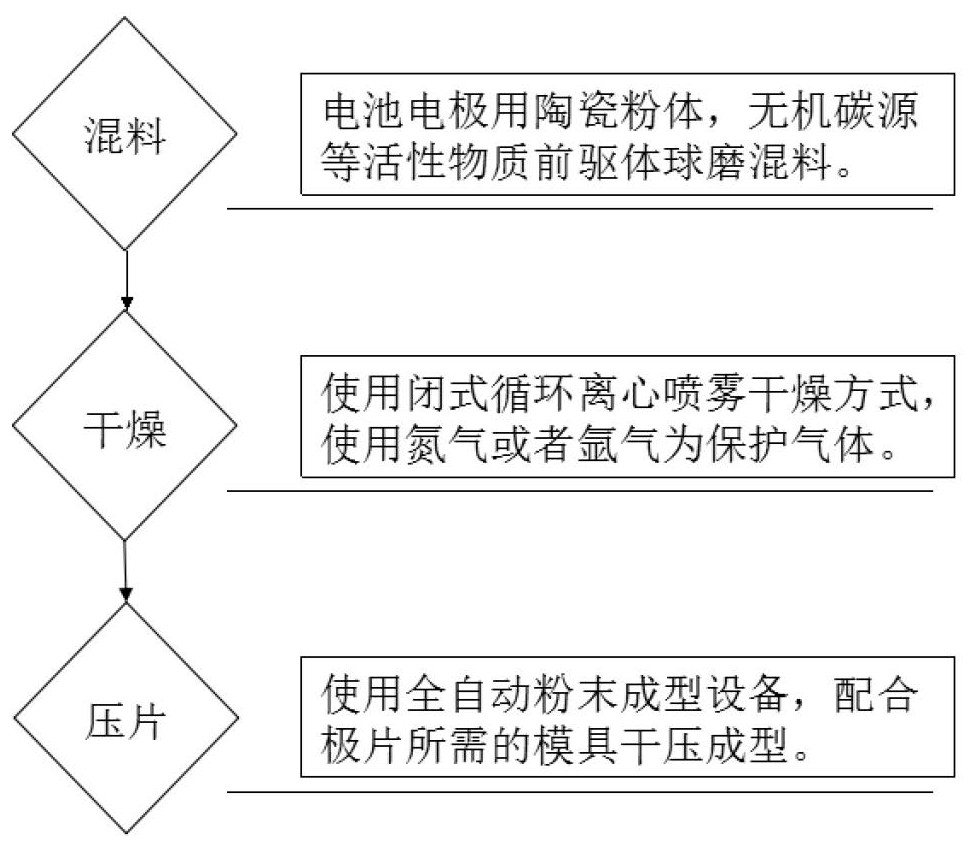

Method used

Image

Examples

Embodiment 1

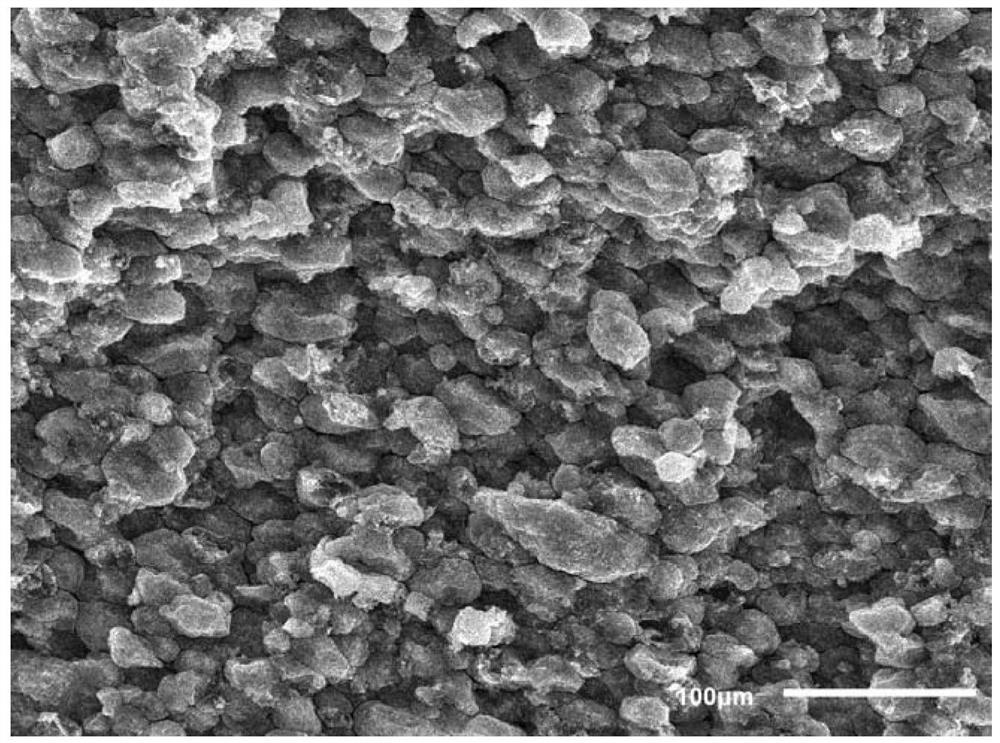

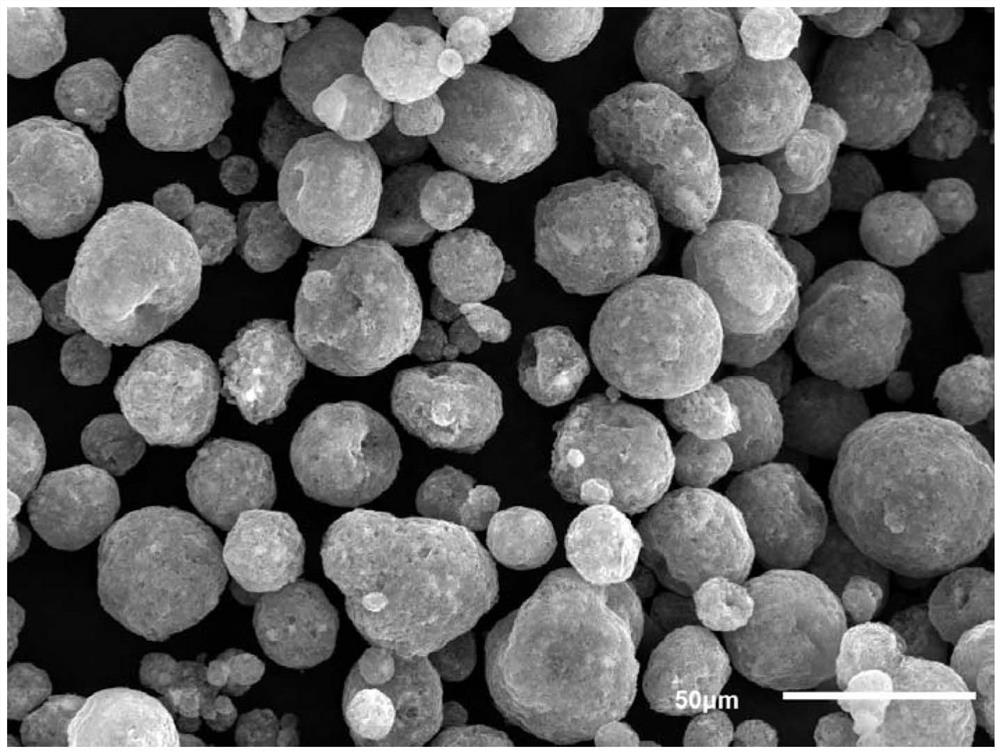

[0049] 50g of positive electrode ceramic powder LiMn 2 o 4 , Inorganic carbon source 10g carbon black, 20g activated carbon, 5g natural graphite powder are raw materials, use absolute ethanol as a solvent, control the solid content of the powder to be 40wt.%, use zirconia as ball milling beads, and the ratio of material to ball is 1:3 , the rough mill was ball milled for 1 h at a speed of 300 rpm to obtain a uniform slurry. Continue to add 15wt.% PVB binder, further ball mill at 200 rpm for 3 hours, and pour out the slurry. The obtained slurry was granulated using a closed-cycle spray granulation process, nitrogen gas was introduced as a protective gas, and the air inlet temperature of the spray drying equipment was set at 120°C. Set the outlet air temperature to 70°C. Set the centrifuge speed to 5000 rpm. Obtain granular powder with uniform particle size, collect ethanol vapor, and facilitate the next recycling. The obtained powder is further automatically batch-prepared...

Embodiment 2

[0056] 70g of positive electrode ceramic powder λ-MnO 2 , Inorganic carbon source 5g carbon black, 10g activated carbon, 5g natural graphite powder are raw materials, use absolute ethanol as a solvent, control the solid content of the powder to be 60wt.%, use zirconia as ball milling beads, and the ratio of material to ball is 1:5 , the rough mill was ball milled at 200 rpm for 2 hours to obtain a uniform slurry. Continue to add 10wt.% PVB binder, further ball mill at 250 rpm for 3 hours, and pour out the slurry. The obtained slurry was granulated using a closed-cycle spray granulation process, nitrogen gas was introduced as a protective gas, and the air inlet temperature of the spray drying equipment was set at 150°C. Set the outlet air temperature to 80°C. Set the centrifuge speed to 10000 rpm. Obtain granular powder with uniform particle size, collect ethanol vapor, and facilitate the next recycling. The obtained powder is further automatically batch-prepared with a pow...

Embodiment 3

[0062] 60g negative electrode ceramic powder NaTi 2 (PO4) 3 , Inorganic carbon source 10g carbon black, 10g activated carbon, 10g natural graphite powder are raw materials, use absolute ethanol as a solvent, control the solid content of the powder to be 30wt.%, use zirconia as ball milling beads, and the ratio of material to ball is 1:5 , a coarse mill at a high speed of 100 rpm / min for 5 hours to obtain a uniform slurry. Continue to add 10wt.% PVB binder, further ball mill at 150 rpm for 4 hours, and pour out the slurry. The obtained slurry was granulated using a closed-cycle spray granulation process, and argon was introduced as a protective gas, and the spray drying equipment was set at an inlet air temperature of 250°C. Set the outlet air temperature to 120°C. Set the centrifuge speed to 10000 rpm. Obtain granular powder with uniform particle size, collect ethanol vapor, and facilitate the next recycling. The obtained powder is further automatically batch-prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com