Foamed-nickel-base loaded ZnCo2O4/ZnWO4 composite material synthesized according to hydrothermal method and application thereof

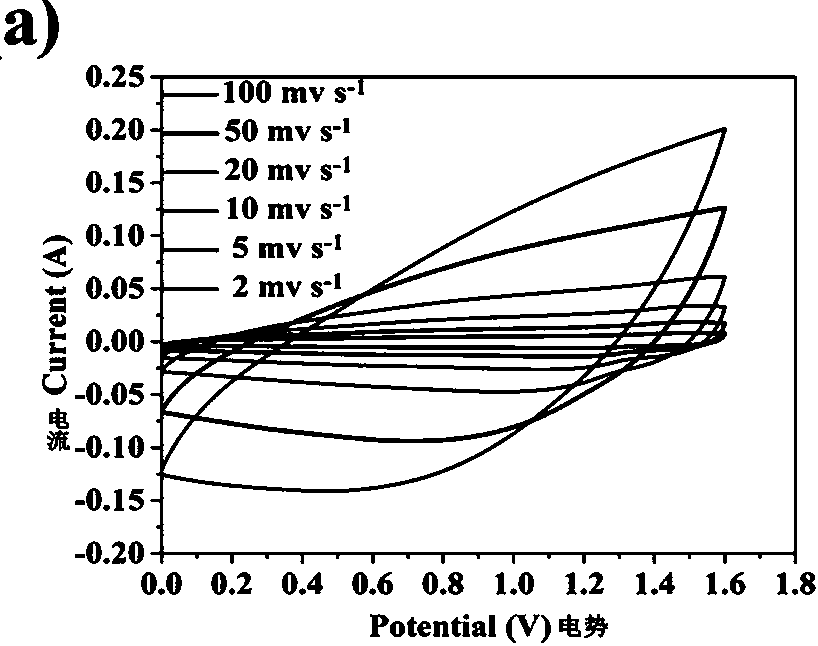

A composite material and a hydrothermal method are applied in the field of synthesizing foamed nickel-based ZnCo2O4/ZnWO4 composite materials by a hydrothermal method to achieve the effects of low cost and low toxicity of raw materials, reduction of energy consumption and cost, and improvement of electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

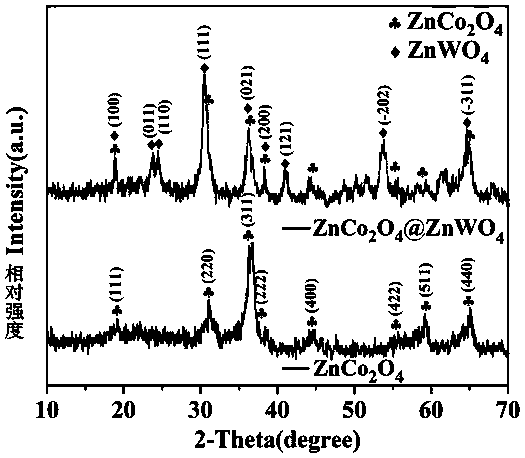

[0039] Hydrothermal Synthesis of Foamed Nickel-Based Supported ZnCo 2 o 4 / ZnWO 4 Composite materials, including the following steps:

[0040] (1) Cut the nickel foam into an appropriate size (1×2cm), wash the nickel foam in the order of hydrochloric acid, ethanol, and deionized water to remove impurities on the surface of the nickel foam, and dry it for later use.

[0041] (2) 1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co (NO 3 ) 2 ·6H 2 O), 2mmol ammonium fluoride (NH 4 F), 5mmol urea (CO(NH 2 ) 2 ) was dissolved in 40ml deionized water, stirred evenly and ultrasonicated for 30min. Then transfer this solution together with the cleaned nickel foam to a 50ml polytetrafluoroethylene-lined reactor, conduct a hydrothermal reaction at 120°C for 5 hours, cool naturally, take out the nickel foam, wash and dry. The nickel foam after the hydrothermal reaction was then calcined at 400°C for 2 hours to obtain ZnCo supported on the...

Embodiment 2

[0044] Hydrothermal Synthesis of Foamed Nickel-Based Supported ZnCo 2 o 4 / ZnWO 4 Composite materials, including the following steps:

[0045] (1) Cut the nickel foam into an appropriate size (1×2cm), wash the nickel foam in the order of hydrochloric acid, ethanol, and deionized water to remove impurities on the surface of the nickel foam, and dry it for later use.

[0046] (2) 1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co (NO 3 ) 2 ·6H 2 O), 2mmol ammonium fluoride (NH 4 F), 5mmol urea (CO(NH 2 ) 2 ) was dissolved in 60ml deionized water, stirred evenly and ultrasonicated for 30min. Then transfer this solution together with the cleaned nickel foam to a 50ml polytetrafluoroethylene-lined reactor, conduct a hydrothermal reaction at 130°C for 6 hours, cool naturally, take out the nickel foam, wash and dry. The nickel foam after the hydrothermal reaction was then calcined at 500°C for 3 hours to obtain ZnCo supported on the...

Embodiment 3

[0049] Hydrothermal Synthesis of Foamed Nickel-Based Supported ZnCo 2 o 4 / ZnWO 4 Composite materials, including the following steps:

[0050] (1) Cut the nickel foam into an appropriate size (1×2cm), wash the nickel foam in the order of hydrochloric acid, ethanol, and deionized water to remove impurities on the surface of the nickel foam, and dry it for later use.

[0051] (2) 1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), 2mmol cobalt nitrate hexahydrate (Co (NO 3 ) 2 ·6H 2 O), 2mmol ammonium fluoride (NH 4 F), 5mmol urea (CO(NH 2 ) 2 ) was dissolved in 50ml deionized water, stirred evenly and ultrasonicated for 30min. Then transfer this solution together with the cleaned nickel foam to a 50ml polytetrafluoroethylene-lined reactor, conduct a hydrothermal reaction at 110°C for 4 hours, cool naturally, take out the nickel foam, wash and dry. The nickel foam after the hydrothermal reaction was then calcined at 300°C for 1 h to obtain ZnCo supported on the nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com