Fiber-bragg-grating-based resonant train bearing damage detection sensor

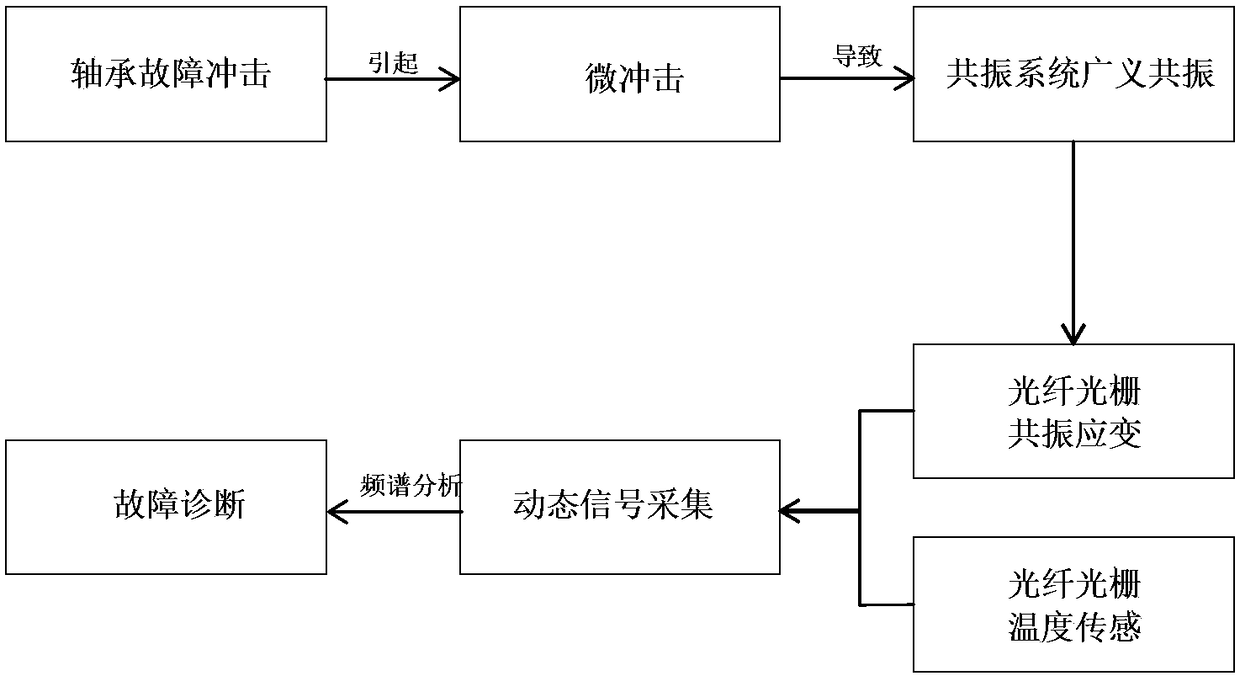

A fiber grating and bearing damage technology is applied in the field of generalized resonance demodulation technology and optical fiber sensing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

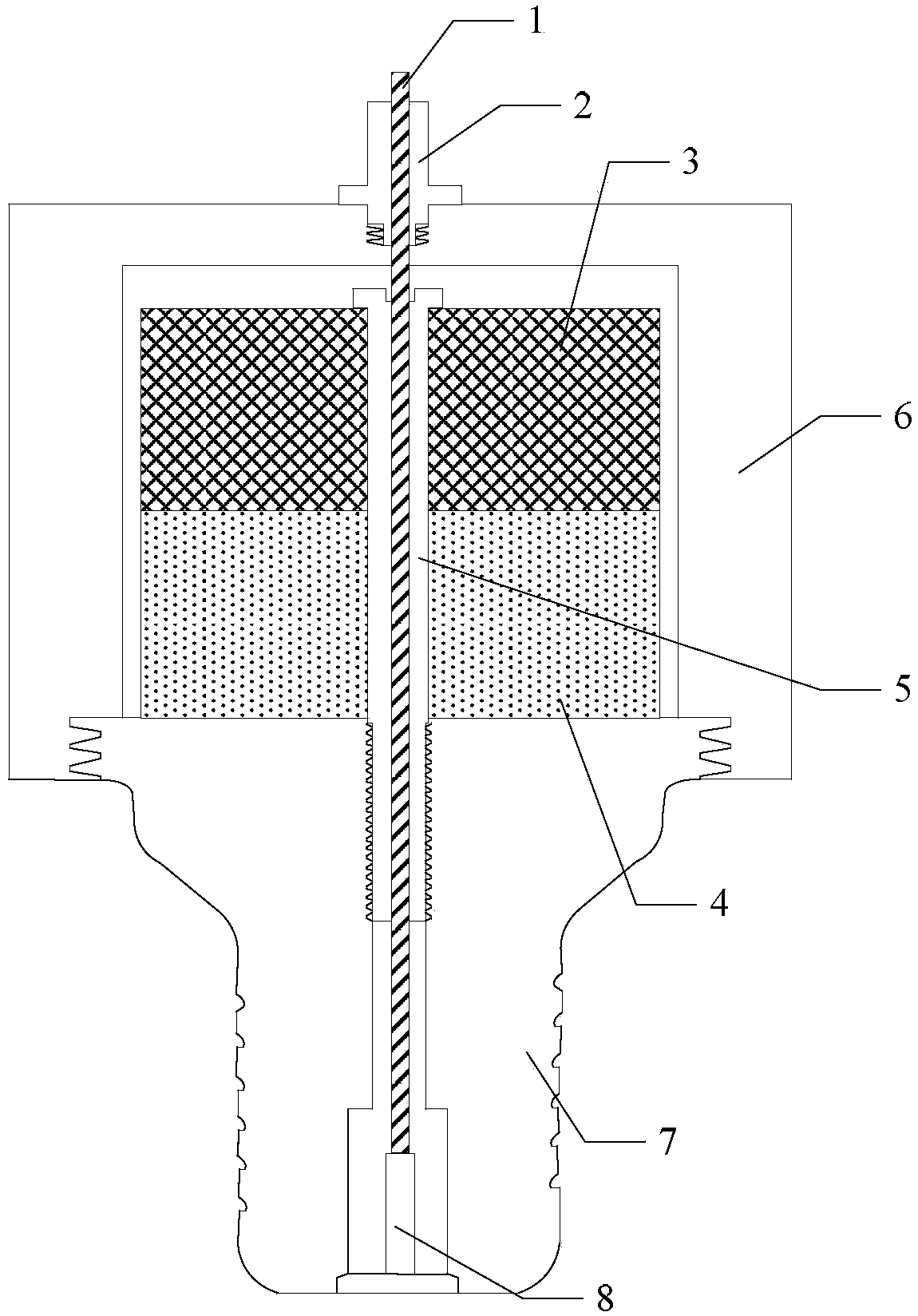

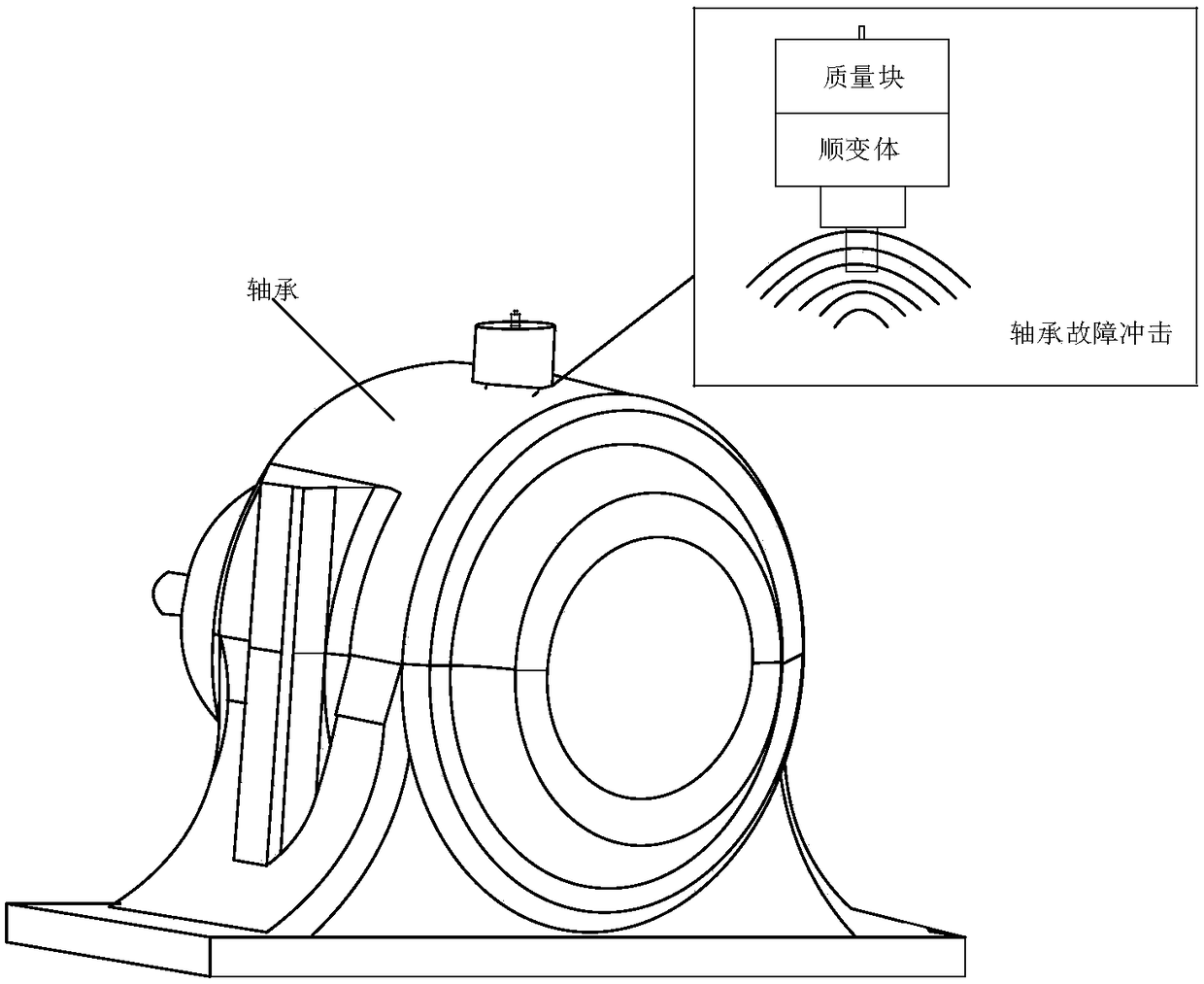

[0023] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the fiber grating-based resonant train bearing damage detection sensor described in this embodiment includes a fiber grating 1, a mass block 3, a variant 4, a bolt 5, a protective shell 6, a mounting base 7 and a fiber grating temperature sensor 8;

[0024] The protective shell 6 is a cavity structure with the top end closed and the bottom end open;

[0025] The opening end of the installation base 7 and the protective shell 6 is connected by threads; the center of the installation base 7 is provided with a vertical installation through hole;

[0026] The mass block 3 and the cis-variant 4 are simultaneously arranged inside the cavity structure of the protective shell 6, and the mass block 3 is located on the top of the cis-variant 4;

[0027] The bolt 5 is provided with an axial center through hole, and the bolt 5 passes through the mass block 3 and the variant body 4 from top t...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment is to further limit the fiber grating-based resonant train bearing damage detection sensor described in Embodiment 1. In this embodiment, an optical fiber protection part 2 is also included;

[0040]The top end of the protective shell 6 is provided with a threading hole with an internal thread, and the optical fiber protection part 2 and the protective shell 6 are connected to the threading hole by threads, and the fiber grating 1 extends out of the protective shell 6 from the central through hole of the optical fiber protection part 2 of the exterior.

[0041] In this embodiment, the fiber protection member 2 is used to fix the protruding part of the fiber Bragg grating 1 to prevent the fiber Bragg grating 1 from being damaged.

specific Embodiment approach 3

[0042] Specific embodiment three: this embodiment further limits the fiber grating-based resonant train bearing damage detection sensor described in specific embodiment one. In this embodiment, the end of the bolt 5 is installed through the screw thread and the mounting base 7 through-hole connection.

[0043] In this embodiment, the connection method is simple and reliable through screw connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com