Support flange disassembling tool and support flange disassembling method

A technology for dismantling tools and flanges, which is applied in the direction of manufacturing tools, hand-held tools, chucks, etc., can solve the problems that the support flange cannot be removed, and achieve the effect of improving the efficiency of cutting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

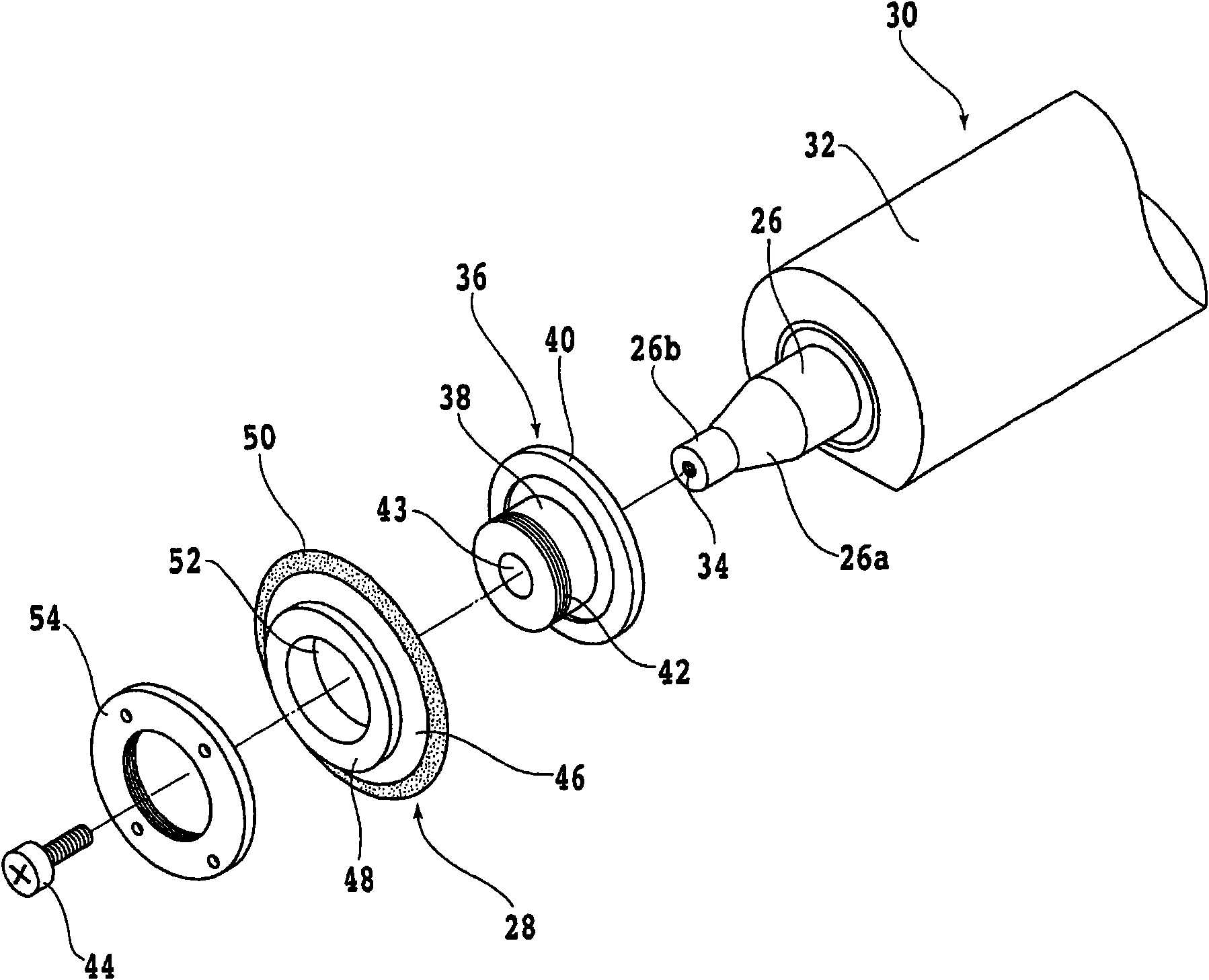

[0031] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The appearance of the cutting device 2 according to the embodiment of the present invention that can cut a semiconductor wafer and divide it into individual chips (devices) is shown.

[0032] On the front surface side of the cutting device 2 is provided an operating member 4 for an operator to input instructions to the device such as machining conditions. A display unit 6 such as a CRT is provided on the upper part of the device, and the display unit 6 displays a guidance screen for an operator and an image captured by an imaging unit described later.

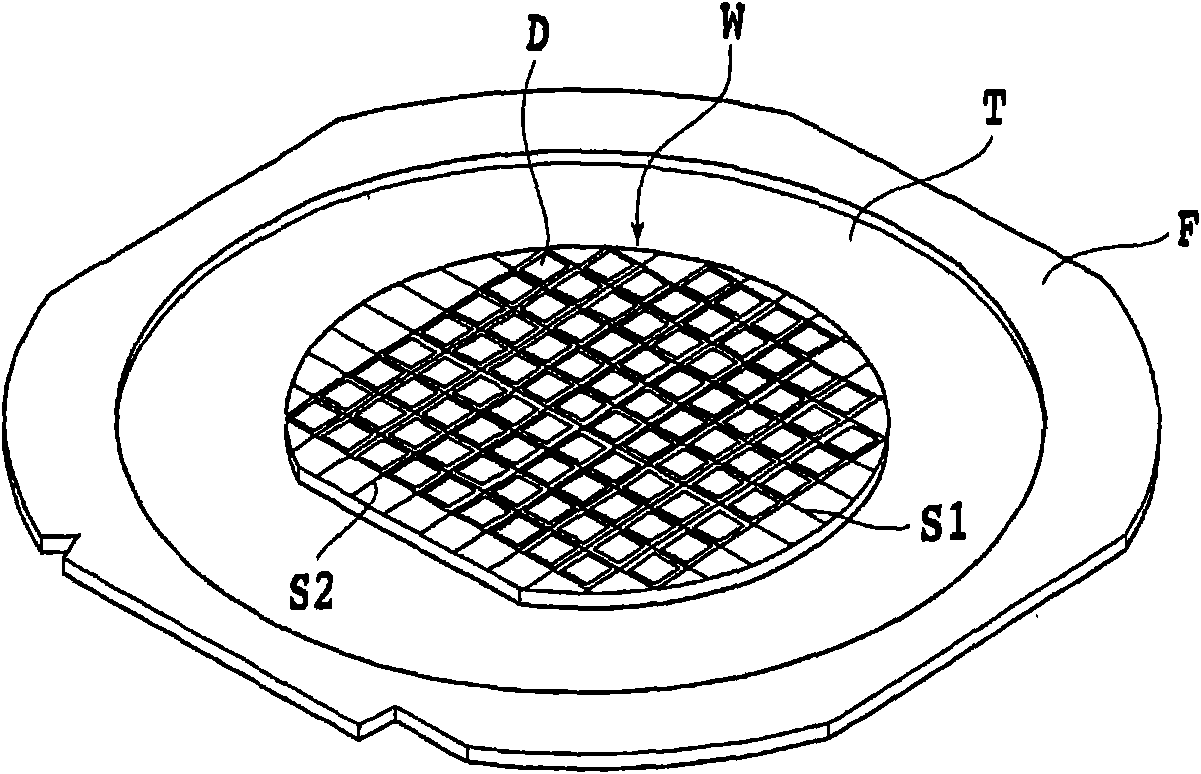

[0033] Such as figure 2 As shown, on the surface of the wafer W as the object of cutting, first and second separation streets S1 and S2 are formed orthogonally, and a plurality of devices D are divided by the first and second separation streets S1 and S2. formed on the wafer W.

[0034] The wafer W i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com