Seal cover

A technology for sealing caps and mechanical parts, applied in the field of metal sealing caps, can solve problems such as damage to the inner peripheral surface of outer ring components, and achieve the effect of effective fitting force and inhibition of detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

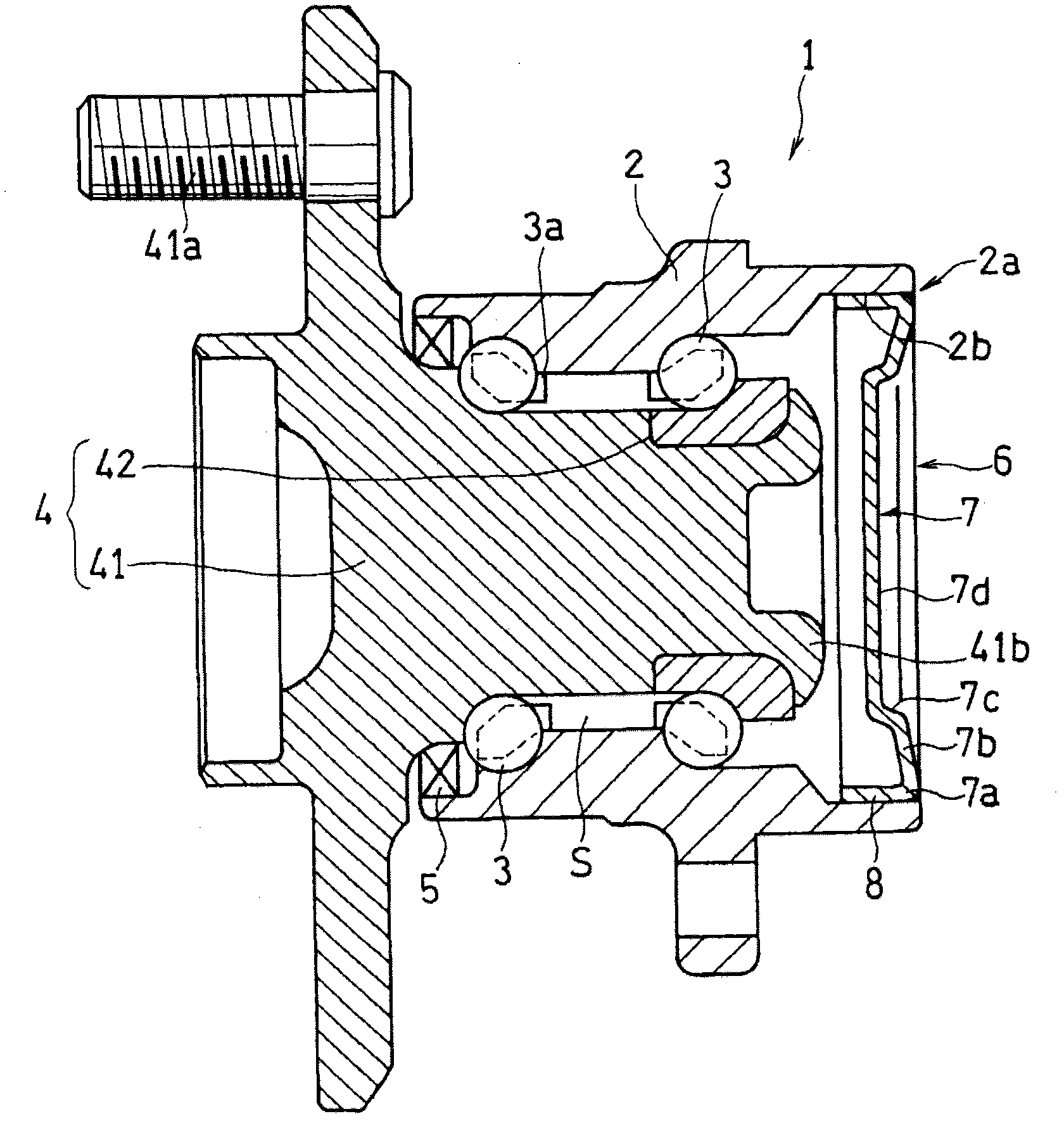

[0024] Embodiments of the present invention will be described below based on the drawings. figure 1 Indicates a bearing device that rotatably supports the driven wheels of an automobile. In the bearing device 1 shown in the illustration, a hub 41 and an inner ring member 42 are axially rotatably supported on an outer ring member (cylindrical mechanical member) fixed to a vehicle body (not shown) via two rows of rolling elements (balls) 3 . . . )2 on the inner diameter part. A driven wheel (rim) not shown is attached to the hub 41 with bolts 41 a. The inner ring 4 on the rotating side is constituted by the hub 41 and the inner ring member 42 . The rolling elements 3 are interposed between the outer ring member 2 and the inner ring 4 while being held by the cage 3 a. Between the wheel-side end portions of the outer ring member 2 and the inner ring 4 along the axial direction of the hub 41 , a shaft seal type seal ring (oil seal) 5 is attached while maintaining a mutual slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com