Fast-charging lithium ion battery and preparation method thereof

A lithium-ion battery and conductive agent technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of affecting the rate performance and cycle performance of materials, inability to apply electric vehicles, irreversible structural changes, etc. Liquid and liquid retention properties, detachment inhibition, and retention effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1 (S1)

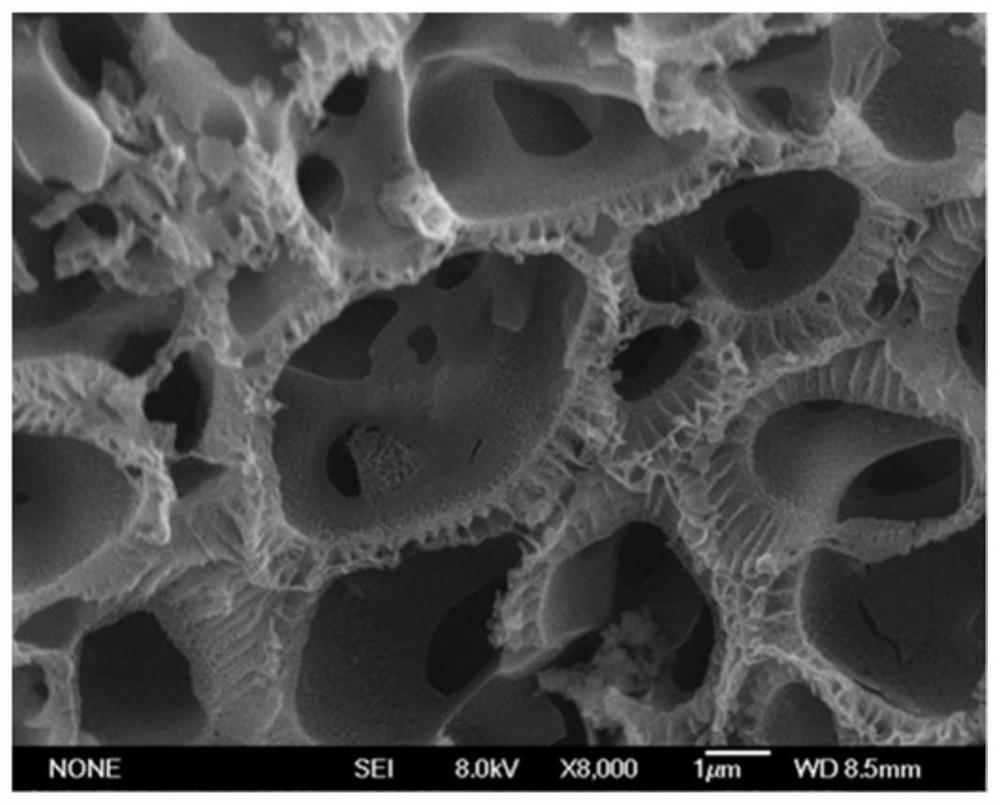

[0076] (1) Add 200g PVDF5130 (polyvinylidene fluoride, positive electrode binder) to 3800g nitrogen methyl pyrrolidone (referred to as NMP, positive electrode solvent) and stir for 2h to disperse it (the solid content of PVDF5130 is 5wt%); then add 270g conductive carbon black (a part of the positive electrode conductive agent), continue to stir for 2h; then add 30g of three-dimensional macroporous carbon (another part of the positive electrode conductive agent) to it, continue to stir for 2h; then add 9500g of lithiated intercalation compound LiNi to it 0.5 co 0.2 mn 0.3 al 0.003 o 2 (Positive electrode active material), stirring for 5 hours to obtain positive electrode slurry; wherein, the particles of the positive electrode active material are secondary spherical particles, and the particle diameter D50 of the particles is 7.5 μm;

[0077] (2) Coating three-dimensional macroporous carbon on a non-porous aluminum foil (type 1235-H18) with a thickn...

Embodiment 2-5

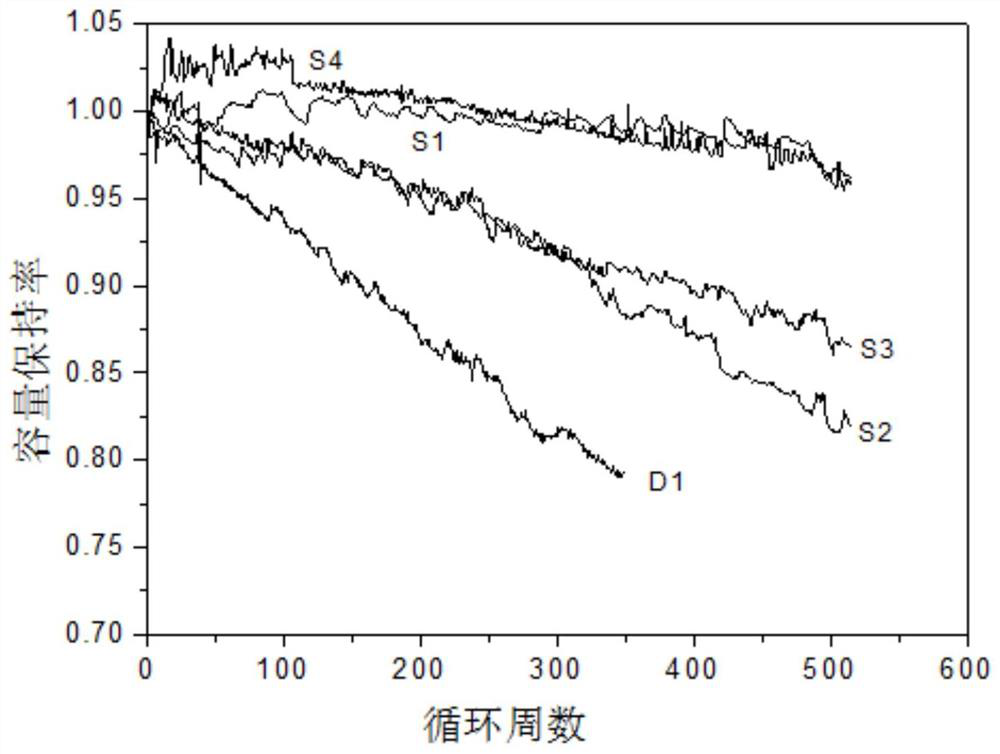

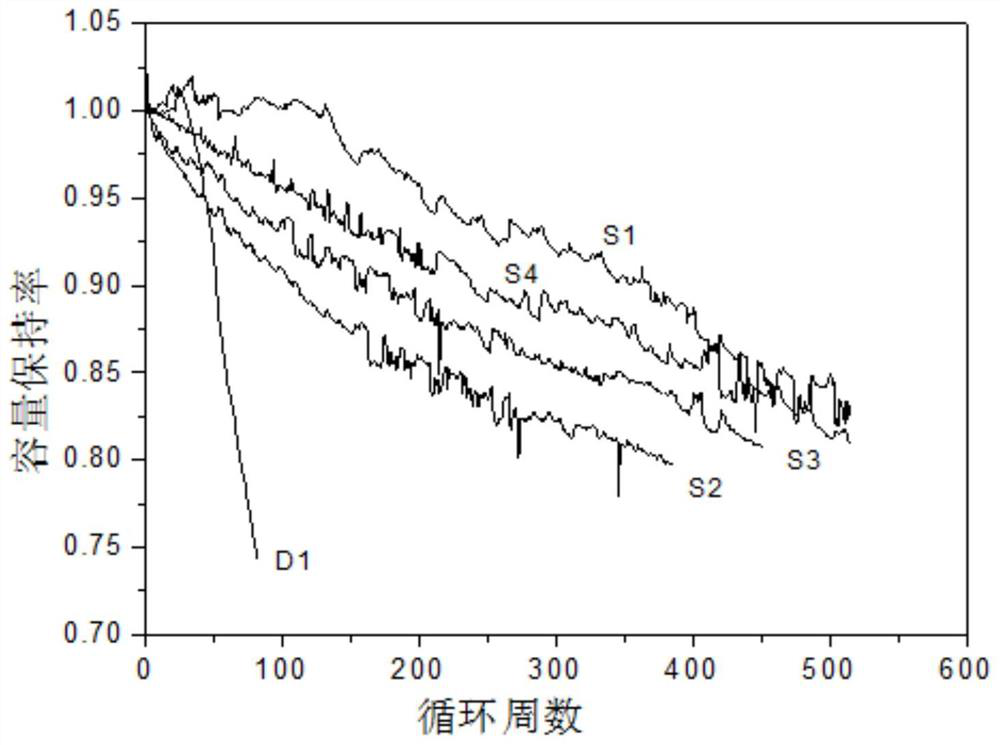

[0081] Embodiment 2-5 (S2-5) and comparative example 1-2 (D1-2)

[0082] A fast-charge lithium-ion battery was prepared according to the method in Example 1. in,

[0083] 1. In embodiment 2, compared with embodiment 1, there are only the following differences:

[0084] The total amount of positive electrode conductive agent remains unchanged, but it is pure conductive carbon black, without adding three-dimensional macroporous carbon;

[0085] The negative current collector is only microporous copper foil, not coated with three-dimensional macroporous carbon;

[0086] The total amount of the negative electrode conductive agent remains unchanged, but it is pure conductive carbon black without adding three-dimensional macroporous carbon.

[0087] 2. In Example 3, compared with Example 1, there are only the following differences:

[0088] The negative current collector is only microporous copper foil, not coated with three-dimensional macroporous carbon;

[0089] The total am...

Embodiment 6-9

[0101] Embodiment 6-9 (S6-9)

[0102] A fast-charge lithium-ion battery was prepared according to the method in Example 1. Wherein, the selection and consumption of each raw material in the embodiment 6-9 are shown in Table 1.

[0103] During the preparation process: the viscosity of the obtained positive / negative electrode slurry, its coating surface density on the positive / negative electrode sheet and the compaction density of the positive / negative electrode sheet are shown in Table 2; among them, Example 2- 5 and in comparative example 1-2, the viscosity of gained positive electrode slurry is respectively 8500cps, 8250cps, 8350cps, 8300cps, 8150cps and 8200cps, the viscosity of gained negative electrode slurry is respectively 3450cps, 3550cps, 3750cps, 3650cps, 3400cps, 3800cps, not Listed in Table 2 again; in embodiment 2-5 and comparative example 1-2, the coating surface density of the obtained positive / negative electrode slurry on the positive / negative electrode sheet a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com