Scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of compressors, can solve problems such as increased internal leakage risk, aggravated compressor leakage, and decreased sealing performance, and achieve the goals of prolonging the pressure build-up time, eliminating internal leakage, and increasing assembly clearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

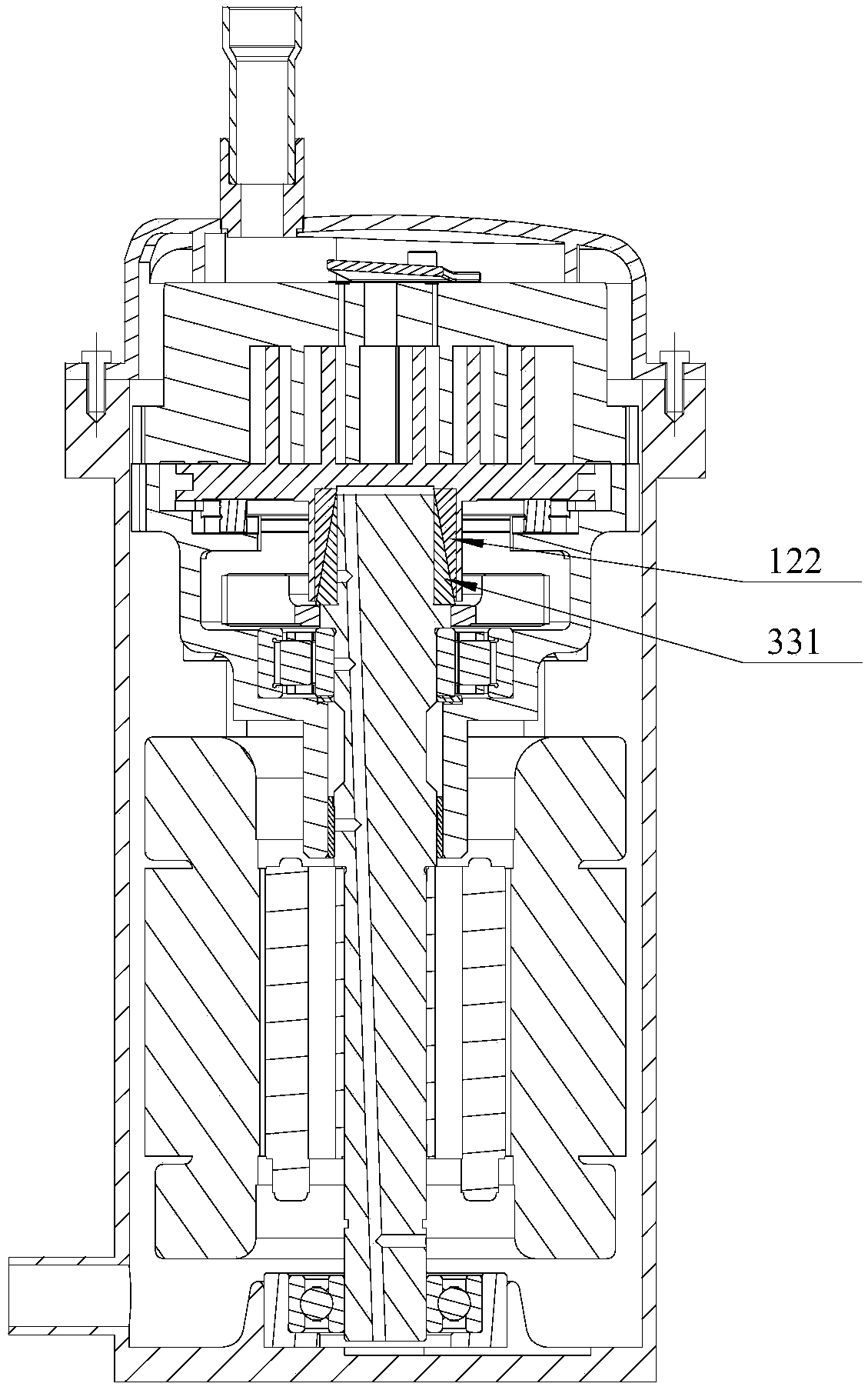

[0033] refer to Figure 1 to Figure 4 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each part of the present invention will be described in detail below, and if there is a description to the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0034] The present invention provides a scroll compressor, including a casing, a compression mechanism and a drive mechanism, the compression mechanism includes a fixed scroll 11 and a movable scroll 12, and the fixed scroll 11 and the movable scroll 12 cooperate A compression chamber is formed, and the casing has a suction pipe 21 communicating with the intake end of the compression chamber and an exhaust pipe 22 communicating with the exhaust end of the compression chamber. The drive mechanism includes a stator 31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com