A manufacturing method of an economical high-precision surface-enhanced Raman active substrate based on high-dielectric materials

A surface-enhanced Raman and manufacturing method technology, applied in the field of physical and chemical detection, can solve the problems of complicated preparation process, high cost, enhanced enhancement effect, etc., and achieve improved process reliability and stability, regular structure, and orderly arrangement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

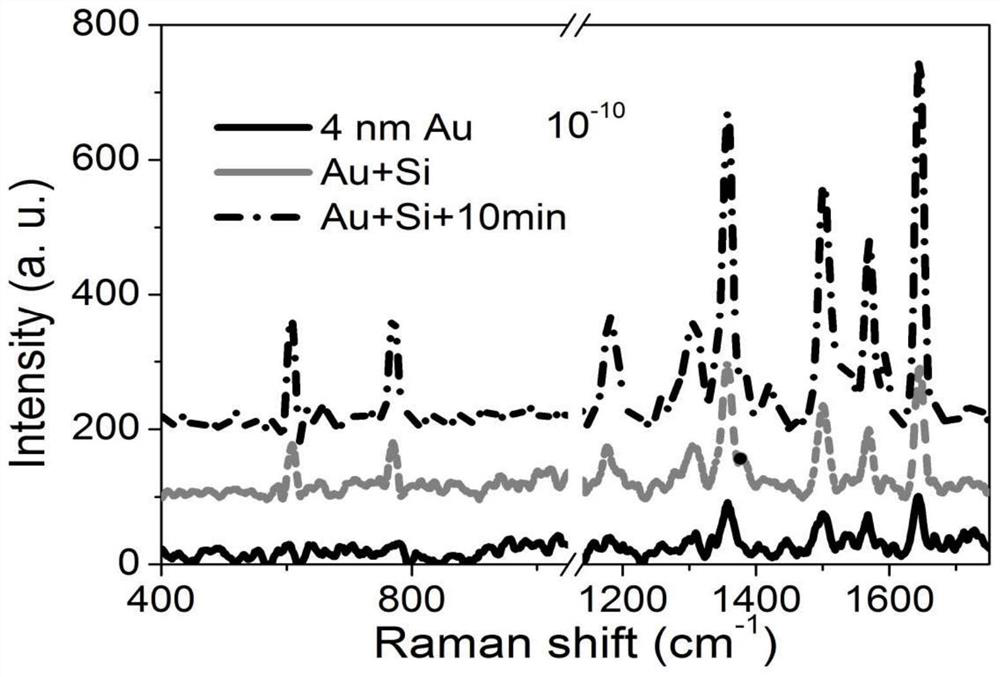

Embodiment 1

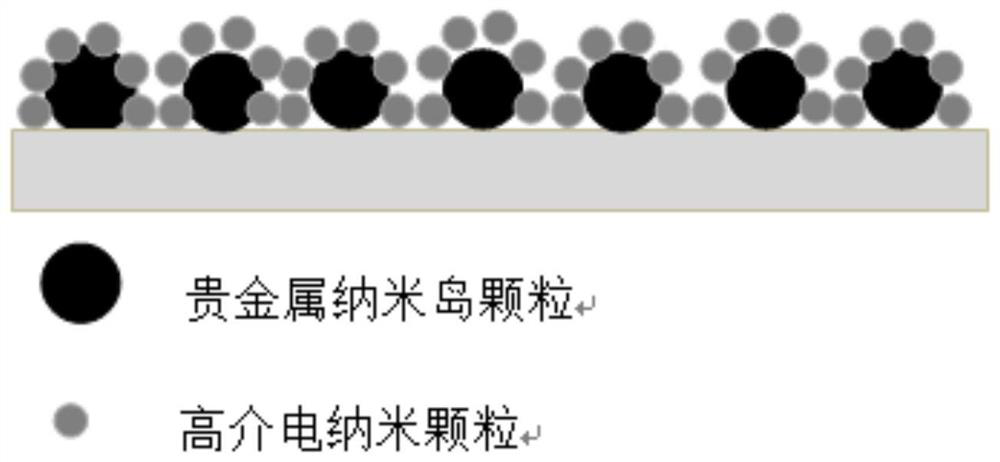

[0024] A method for manufacturing an economical high-precision surface-enhanced Raman active substrate based on high-dielectric materials, comprising the following steps:

[0025] (1) Preparation of noble metal nano-islands

[0026] ① Use magnetron sputtering equipment to sputter the precious metal target onto the surface of clean quartz glass to form an ultra-thin nano-film layer of noble metal on the surface of quartz glass. The magnetron sputtering speed is controlled at 32nm / min, and the sputtering time is 7.6 seconds, the actual thickness of the noble metal nano-film layer is 4nm, where the noble metal target is a gold target;

[0027] ②Put the prepared noble metal nano-film layer into a muffle furnace and anneal at 200°C for 30 minutes to obtain a noble metal nano-island structure;

[0028] (2) Deposition of high dielectric nanoparticle materials

[0029] ① Use magnetron sputtering equipment to sputter the high dielectric target onto the surface of the noble metal nano...

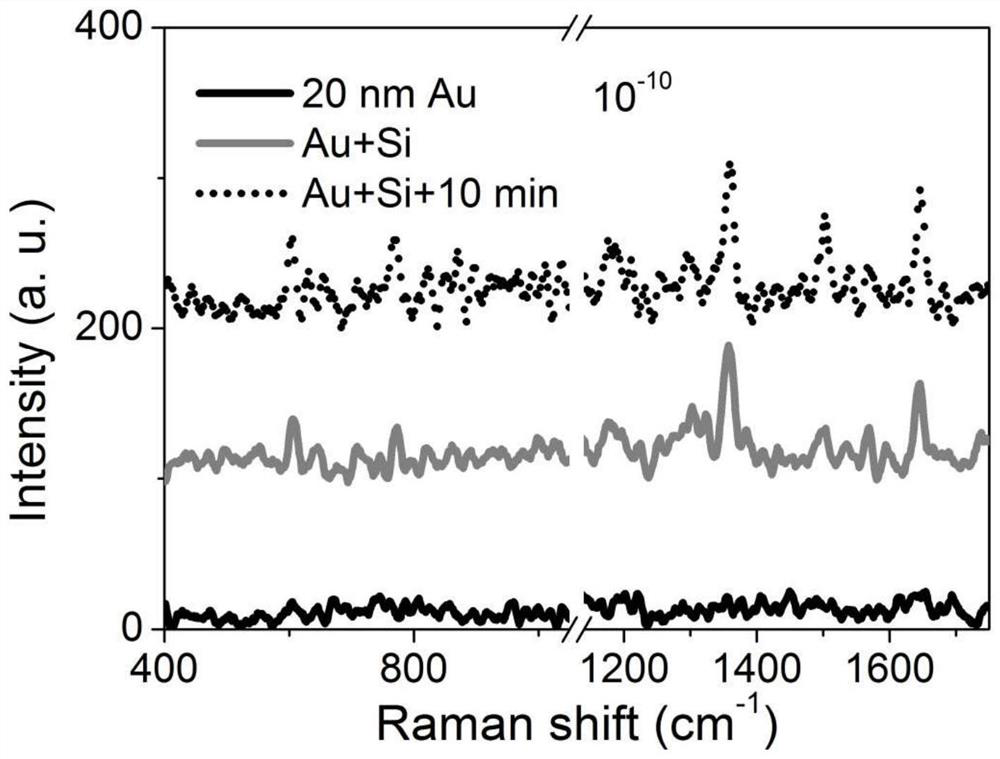

Embodiment 2

[0037] A method for manufacturing an economical high-precision surface-enhanced Raman active substrate based on high-dielectric materials, comprising the following steps:

[0038] (1) Preparation of noble metal nano-islands

[0039] ①Use magnetron sputtering equipment to sputter noble metal target (gold target) onto the surface of clean quartz glass to form an ultra-thin noble metal nano-film layer on the surface of quartz glass. The magnetron sputtering speed is controlled at 32nm / min. The sputtering time is 38 seconds, and the actual thickness of the noble metal nano-film layer is 20nm;

[0040] ②Put the prepared noble metal nano-film layer into a muffle furnace and anneal at 200°C for 30 minutes to obtain a noble metal nano-island structure;

[0041] (2) Deposition of high dielectric nanoparticle materials

[0042] ①Use magnetron sputtering equipment to sputter the high dielectric target (silicon target) onto the surface of the noble metal nano-island structure prepared i...

Embodiment 3

[0050] A method for manufacturing an economical high-precision surface-enhanced Raman active substrate based on high-dielectric materials, comprising the following steps:

[0051] (1) Preparation of noble metal nano-islands

[0052] ①Use magnetron sputtering equipment to sputter noble metal target (gold target) onto the surface of clean quartz glass to form an ultra-thin noble metal nano-film layer on the surface of quartz glass. The magnetron sputtering speed is controlled at 32nm / min. The sputtering time is 3.8 seconds, and the actual thickness of the noble metal nano-film layer is 2nm;

[0053] ②Put the prepared noble metal nano-film layer into a muffle furnace and anneal at 200°C for 30 minutes to obtain a noble metal nano-island structure;

[0054] (2) Deposition of high dielectric nanoparticle materials

[0055] ①Use magnetron sputtering equipment to sputter the high dielectric target (silicon target) onto the surface of the noble metal nano-island structure prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com