Environment-friendly high-temperature resistant antistatic insulation varnish composition for machine room cable

A technology of high temperature resistance and antistatic, which is applied in the field of environment-friendly high temperature resistant and antistatic insulating varnish composition for cables in computer rooms. It can solve the problems of insufficient light and electromagnetic shielding ability, high replacement and maintenance costs, weak antistatic ability, etc., and achieve good safety. Protection and electromagnetic shielding, convenient and fast application and fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

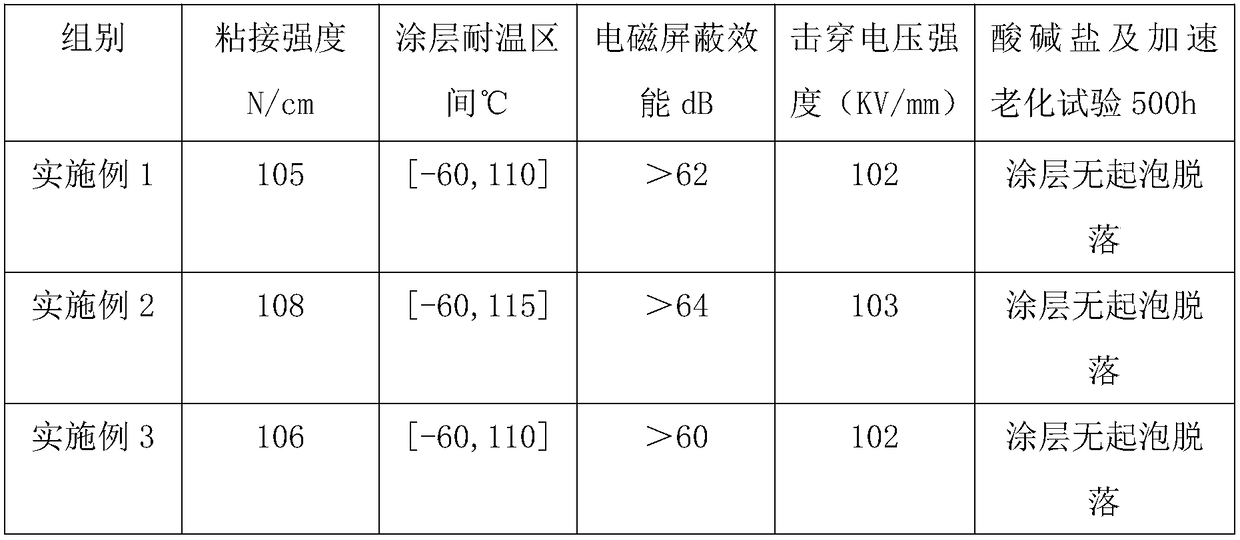

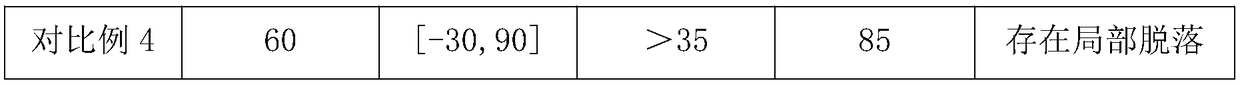

Embodiment 1

[0028] An environment-friendly high-temperature-resistant and anti-static insulating paint composition for cables in a computer room, including the following raw materials: 50 kg of silicone modified epoxy resin, 8 kg of methyl vinyl silicone rubber, 10 kg of epoxy acrylate, 4 kg of polyvinyl acetate emulsion, tributyl phosphate Ester 1kg, fumed silica 3kg, shark liver oil 1kg, fiber gypsum 2kg, modified clinoptilolite 2kg, zirconia 1.5kg, ethyl acetate 7kg, calcium lignosulfonate 0.6kg, curing aid 1kg, coupling Agent 0.4kg and antistatic agent 0.3kg;

[0029] The properties and parameters of the above-mentioned part of the raw materials are as follows:

[0030] (1) Modified clinoptilolite: get 2kg of clinoptilolite raw material, grind to 60 microns, first place temperature as 40 ℃, mass concentration is 10% sodium hydroxide hot alkali solution and stir for 2.5h, stirring speed is 100r / min, after alkalization, filter, wash and dry, roast at 280°C for 35min, then add 0.15kg of...

Embodiment 2

[0039] An environment-friendly high temperature resistant and antistatic insulating paint composition for cables in a computer room, comprising the following raw materials: 55 kg of silicone modified epoxy resin, 10 kg of methyl vinyl silicone rubber, 15 kg of epoxy acrylate, 5 kg of polyvinyl acetate emulsion, tributyl phosphate Esters 1.25kg, fumed silica 4kg, shark liver oil 1.1kg, fiber gypsum 2.5kg, modified clinoptilolite 2.5kg, zirconium dioxide 2kg, ethyl acetate 8kg, calcium lignosulfonate 0.8kg, curing aid 1.5 kg, coupling agent 0.5kg and antistatic agent 0.4kg;

[0040] The properties and parameters of the above-mentioned part of the raw materials are as follows:

[0041] (1) Modified clinoptilolite: get 2.5kg of clinoptilolite raw material, grind it to 65 microns, and first place it in a hot alkali solution of sodium hydroxide with a temperature of 42°C and a mass concentration of 12% and stir for 2.2h, the stirring speed 110r / min, after alkalization, filter, wash...

Embodiment 3

[0050]An environment-friendly high temperature resistant and antistatic insulating paint composition for cables in a computer room, comprising the following raw materials: 60 kg of silicone modified epoxy resin, 12 kg of methyl vinyl silicone rubber, 20 kg of epoxy acrylate, 6 kg of polyvinyl acetate emulsion, tributyl phosphate Esters 1.5kg, fumed silica 5kg, shark liver oil 1.2kg, fiber gypsum 3kg, modified clinoptilolite 3kg, zirconium dioxide 2.5kg, ethyl acetate 9kg, calcium lignosulfonate 1kg, curing aid 2kg, even Joint agent 0.6kg and antistatic agent 0.5kg;

[0051] The properties and parameters of the above-mentioned part of the raw materials are as follows:

[0052] (1) Modified clinoptilolite: take 3kg of clinoptilolite raw material, grind to 70 microns, first place the temperature in 44°C and 15% sodium hydroxide hot alkali solution and stir for 2h, the stirring speed is 120r / min, after alkalization, filter, wash and dry, roast at 300°C for 30min, then add 0.25kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap