Ceramic substrate material with high strength and high thermal expansion and preparation method of ceramic substrate material

A high thermal expansion, ceramic substrate technology, applied in ceramic ball grid array packaging, high strength and high thermal expansion ceramic substrate materials and their preparation fields, can solve problems such as poor serialization of thermal expansion coefficients of substrate materials, large span of thermal expansion coefficients, and environmental pollution. , to achieve the effect of low production cost, stable material performance and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

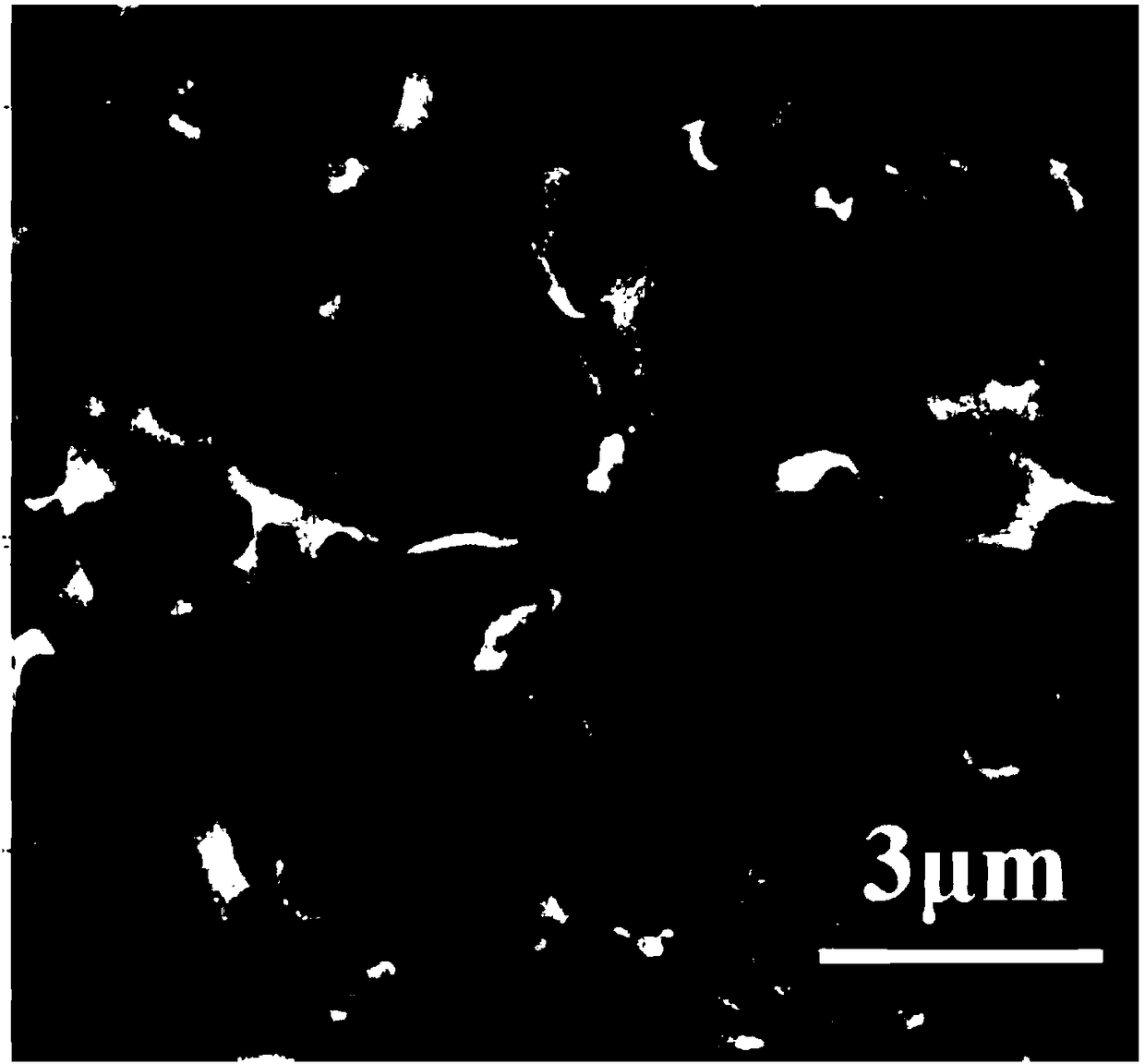

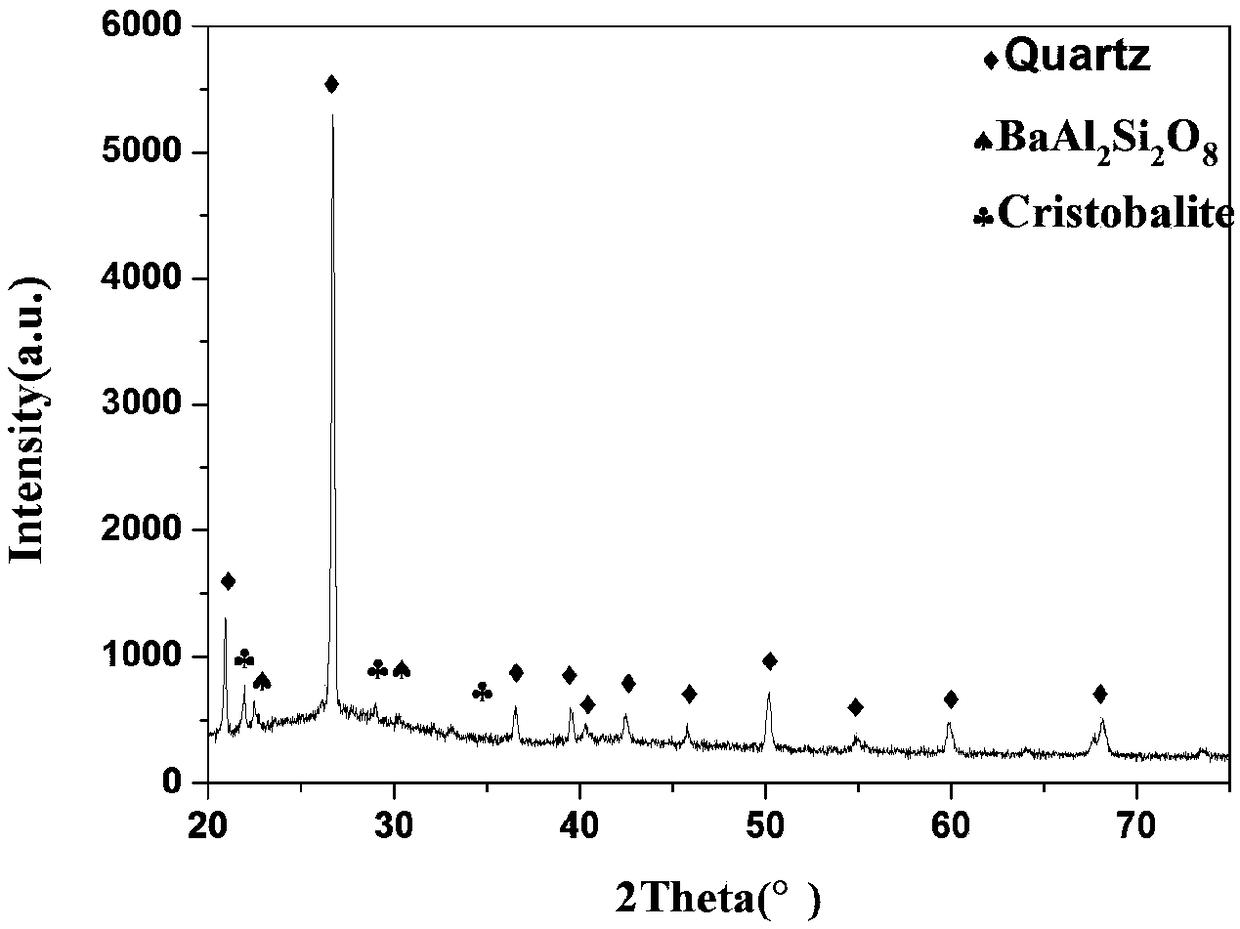

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

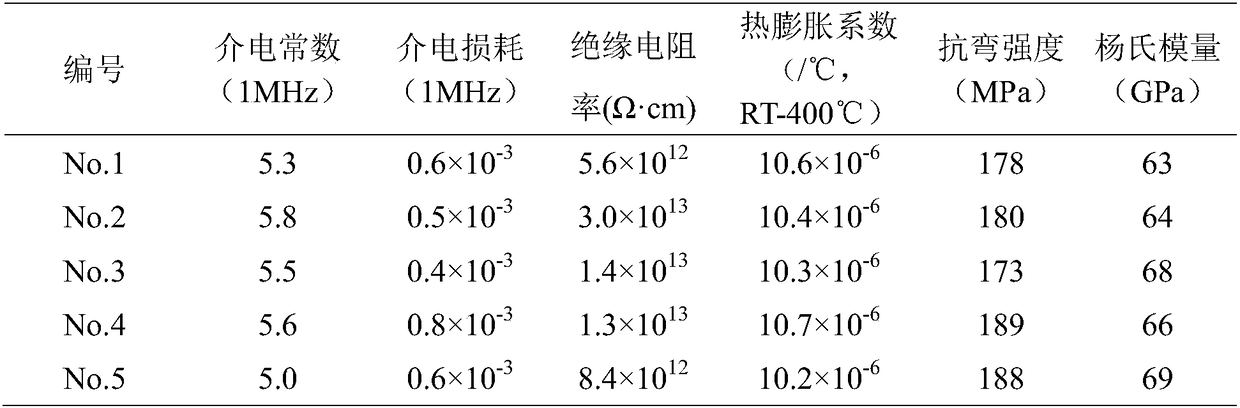

[0026] In the specific embodiment of the present invention, 5 examples are provided, respectively numbered No. 1 to 5, and the specific components of the high-strength and high thermal expansion coefficient ceramic substrate material are shown in the following table:

[0027] Numbering

B 2 o 3

BaO

SiO 2

al 2 o 3

ZrO 2 +Sm 2 o 3

No.1

5

25

65

1

4

No.2

7

28

60

2

3

No.3

8

26

55

4

7

No.4

10

27

58

3

2

No.5

6

32

59

2

1

[0028] Its preparation process is as follows:

[0029] Calculate the actual amount of raw materials for each component according to the weight percentage of the oxides used in the formula in Table 1. After weighing and mixing evenly, the mixed powder obtained after ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com