Mixing proportion and preparation method of high-performance light-weight aggregate concrete

A lightweight aggregate concrete, high-performance technology, applied in the field of building materials, can solve the problem of fiber concrete staying in the ordinary concrete stage, etc., to reduce the adverse effect of compressive strength growth, increase the bonding force, and increase the bonding force. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

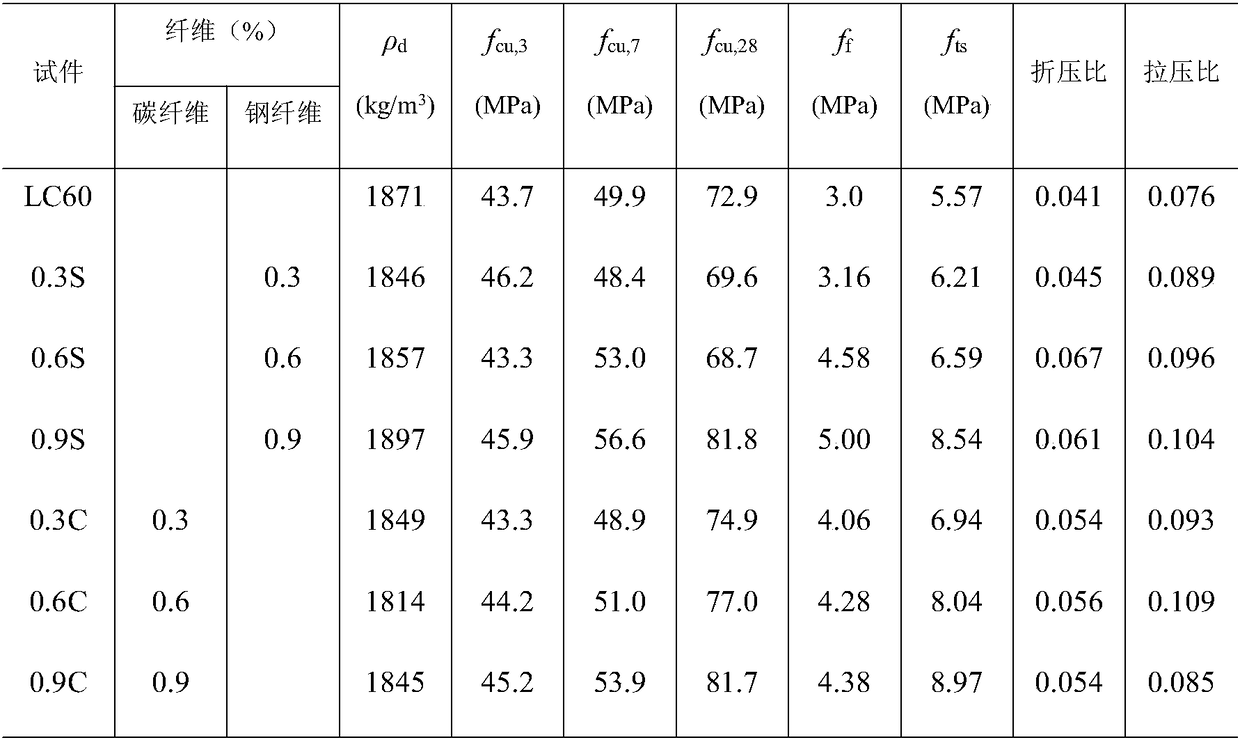

[0073] Table 1 Mixing proportions of different fiber additions affecting the mechanical properties of lightweight aggregate concrete

[0074]

[0075] It can be seen from the above table that the addition of steel fiber and carbon fiber alone has little effect on the 3-day compressive strength of lightweight aggregate concrete, and the 28-day strength of fiber on 28-day light aggregate concrete has increased. With the growth of the period, the bonding strength between the matrix and the fiber increases, and the strengthening effect of the fiber is more obvious at 28 days than at 3 days. The incorporation of fibers can significantly increase the compression ratio of lightweight aggregate concrete, and can significantly increase the compression ratio of lightweight aggregate concrete. Under comprehensive comparison, it can be proved that the mixing ratio of adding 0.9% fiber given by the present invention is the optimal mixing ratio, and it has the most significant increase i...

example 2

[0076] Example 2: The high-strength lightweight aggregate concrete of LC40 is configured on the basis of the high-strength lightweight aggregate concrete mix ratio of LC40 provided in the present invention.

[0077]

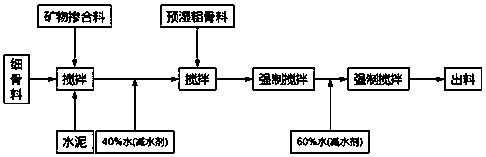

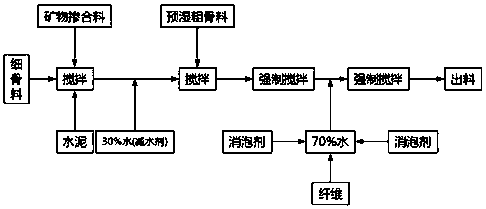

[0078] The cement used is P.O 42.5 cement; the cementitious material is a composite cementitious material composed of cement, fly ash and silica fume; the fineness modulus of fine aggregate is greater than 2.56, and the apparent density is 2620kg / m 3 The natural medium sand; the coarse aggregate adopts 900-grade crushed stone shale lightweight aggregate ceramsite with 5-16mm continuous gradation, and the apparent density is 1512kg / m 3 ; The superplasticizer is BKS-199 polycarboxylate high-efficiency superplasticizer. The configuration method is as described in the present invention: put mineral admixture, fine aggregate and cement into the mixer, and stir for 30 seconds; add 40% water containing water reducing agent during the mixing process to form a wet mate...

example 3

[0081] Example 3: configure the high-strength lightweight aggregate concrete of LC50 based on the high-strength lightweight aggregate concrete mix ratio of LC50 provided in the present invention.

[0082]

[0083] The cement used is P.O42.5 cement; the cementitious material is a composite cementitious material composed of cement, fly ash and silica fume; the fine aggregate adopts a fineness modulus greater than 2.56 and an apparent density of 2620kg / m 3 The natural medium sand; the coarse aggregate adopts 900-grade crushed stone shale lightweight aggregate ceramsite with 5-16mm continuous gradation, and the apparent density is 1512kg / m 3 ; The superplasticizer is BKS-199 polycarboxylate high-efficiency superplasticizer. The configuration method is as described in the present invention: put mineral admixture, fine aggregate and cement into the mixer, and stir for 30 seconds; add 40% water containing water reducing agent during the mixing process to form a wet material; add p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com