A waterproof membrane production system

A production system and waterproof membrane technology, applied in the direction of layered products, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems of large safety hazards in powder feeding devices and inapplicable waterproof membrane production devices, etc. To achieve the effect of optimizing equipment layout, facilitating promotion and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

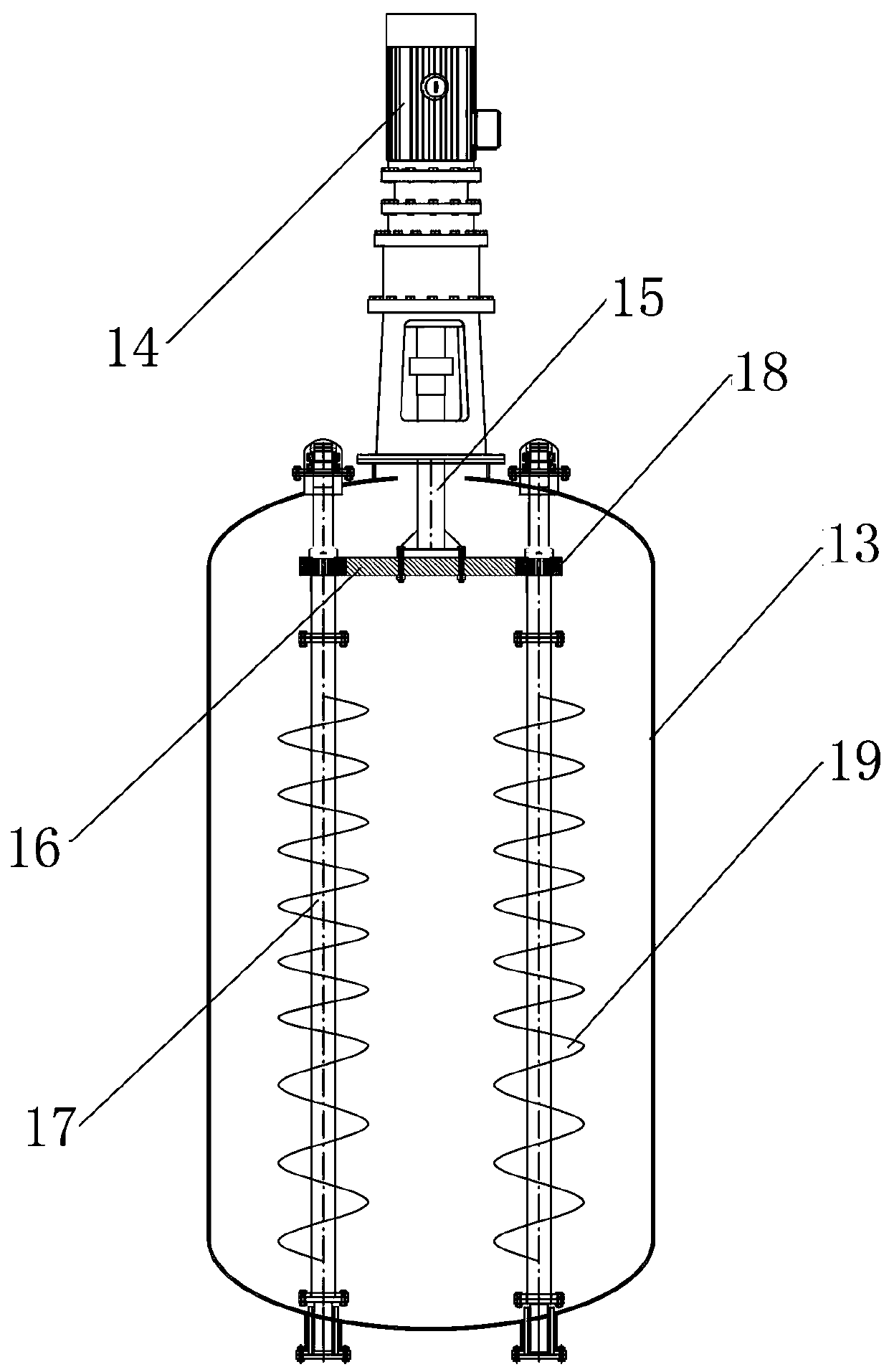

[0036] The invention includes modified asphalt systems and coil forming systems.

[0037] The modified asphalt system includes mixing tanks, asphalt storage tanks and powder conveying devices to prepare modified asphalt materials. Such as Figure 2~4 As shown, the mixing tank includes a tank body 13 with a feed inlet and a discharge port, and a heating device is also provided on the tank body 13 to heat the asphalt material in the tank to keep it in a molten state, so that the asphalt and Mix the powder. The asphalt storage tank is used to store asphalt, and a pipeline is connected between the asphalt storage tank and the tank body 13, and an asphalt pump is arranged on the pipeline.

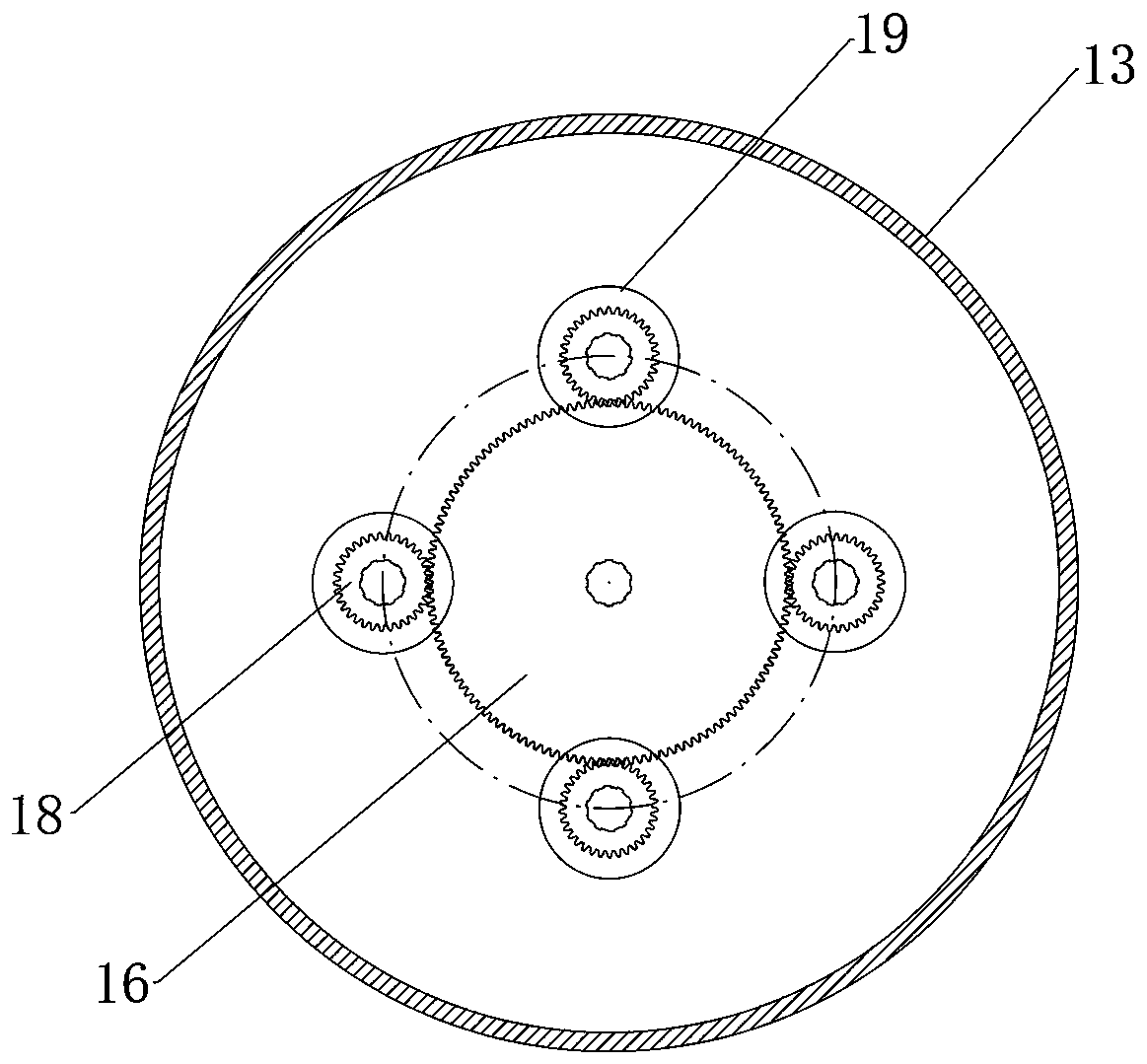

[0038] The top of the tank body 13 is provided with a driver 14, and the output end of the driver 14 is provided with a transmission main shaft 15, and the transmission main shaft 15 vertically extends downwards into the inside of the tank body 13, and a drive wheel 16 is provided at the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com