Dust collecting device and blowing and sucking machine with same

A technology of dust collecting device and blowing suction machine, which is applied in the field of blowing suction machine and dust collecting device, can solve the problems of inability to meet the demand of suction efficiency and the adjustment function without air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

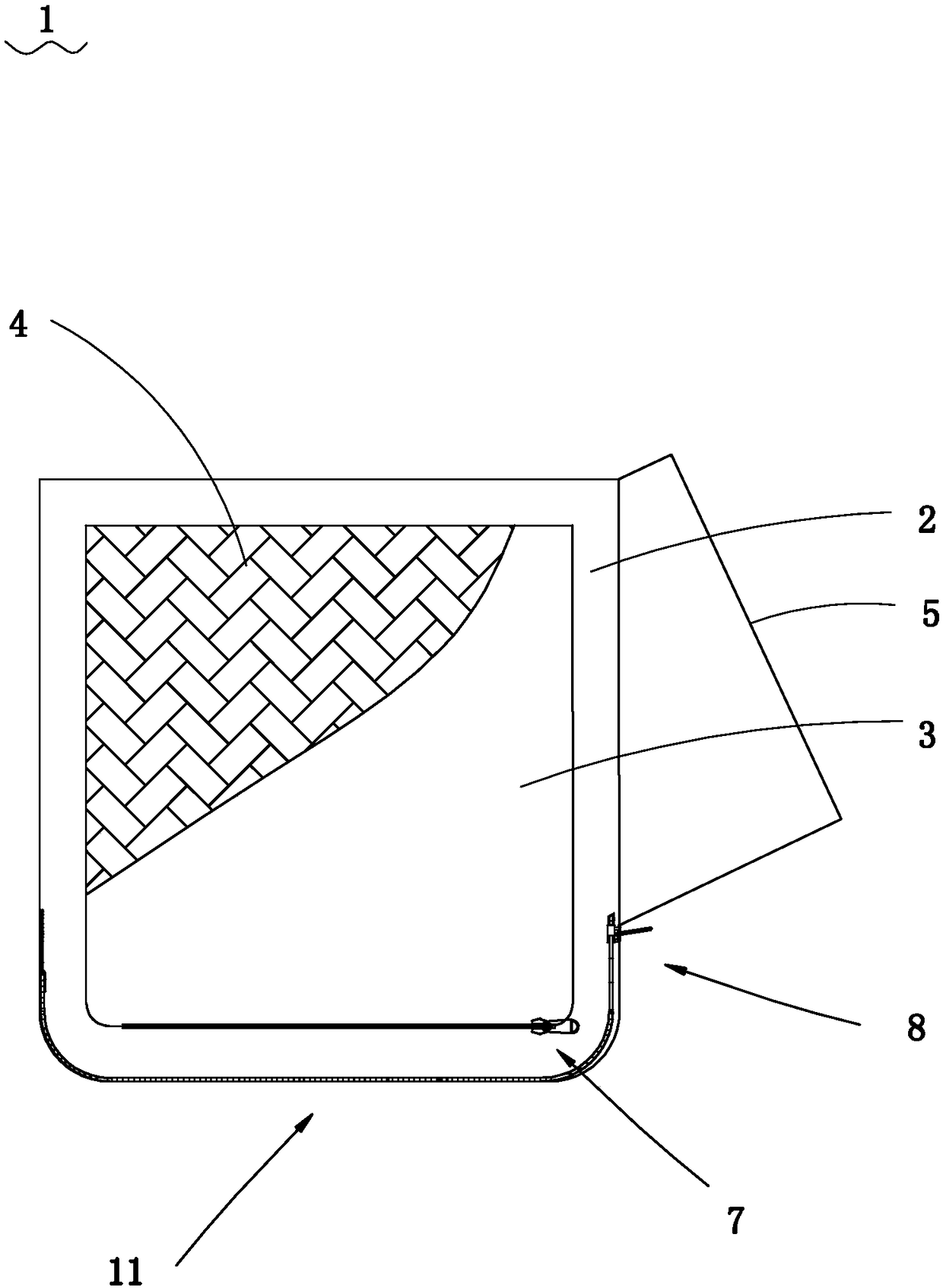

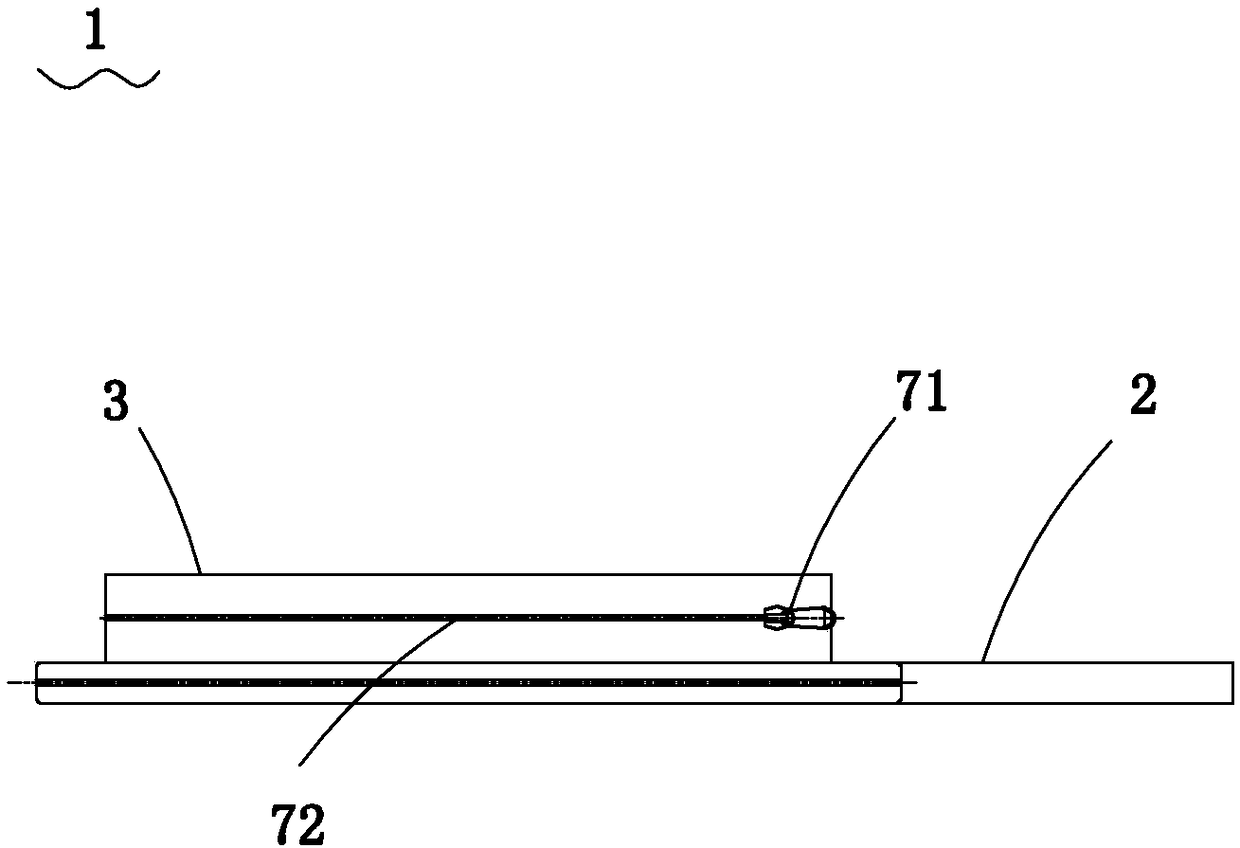

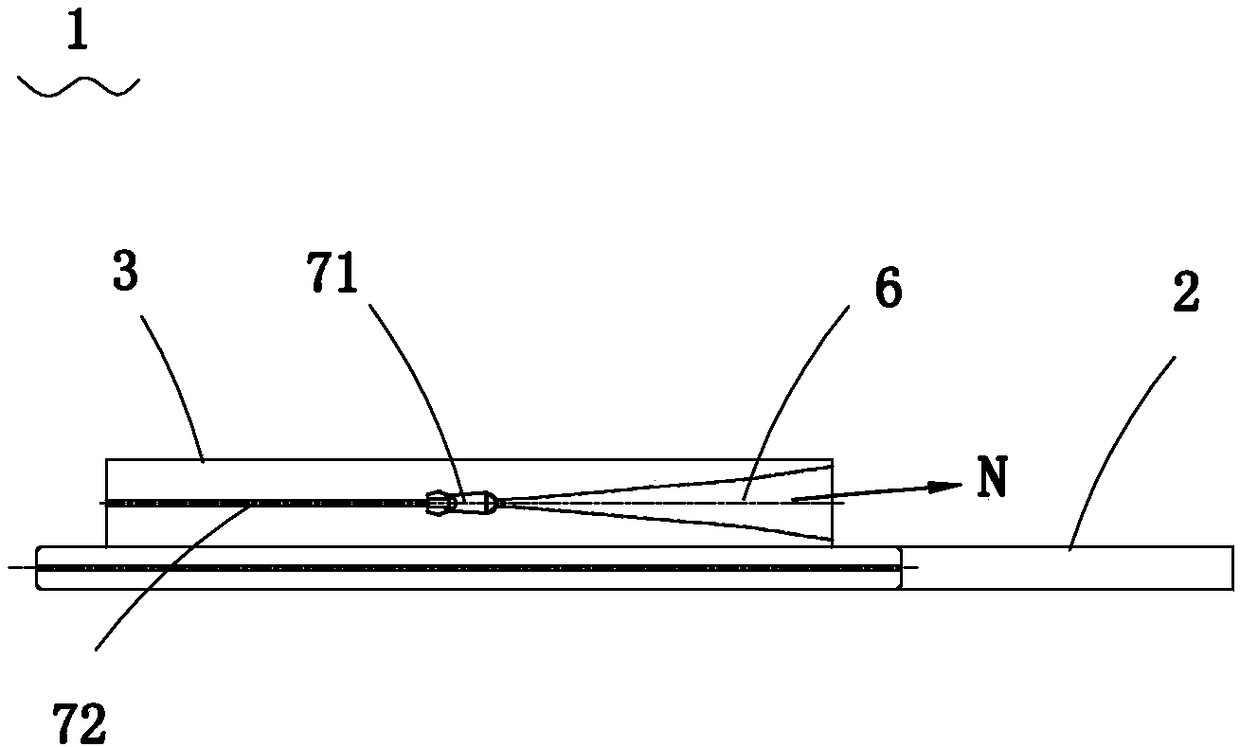

[0039] Refer to attached figure 1 to attach image 3 , in this embodiment, a dust collecting device 1 that can be connected to a blower as an accessory, it includes a body 2 and a dust inlet 5, the body 2 is also provided with an air outlet 4 with better air permeability, and the air outlet The air outlet rate of the part 4 is higher than that of the body 2, or the body 2 is also made of airtight material. In this embodiment, the dust collecting device 1 further includes an adjustment part which is composed of the cover 3 , the air outlet 6 and the air outlet zipper 7 and can adjust the air outlet area of the air outlet 4 .

[0040] Refer to attached figure 1 to attach image 3 , in this embodiment, the adjustment part includes a cover 3, and the cover 3 is encased on the outer surface of the air outlet 4. The air outlet rate of the cover 3 is lower than that of the air outlet 4. In addition, the cover 3 Can also be made of non-breathable material. It should be noted th...

no. 2 example

[0044] Refer to attached Figure 4 to attach Figure 5 , in this embodiment, the dust collecting device 1a includes a main body 2, an air outlet 4 and a dust inlet 5, the main body 2 is also provided with an air outlet 4 with better air permeability, and the air outlet rate of the air outlet 4 is higher than that of the main body 2, or the body 2 can also be made of airtight material.

[0045] Refer to attached Figure 4 to attach Figure 5 , in this embodiment, the regulating part includes a shielding part 9 that is movable relative to the air outlet part 4, wherein the shielding part 9 is made of an airtight material, and the shielding part can also be made of a material with a lower air permeability than the air outlet part 4. become. It should be noted that in this embodiment, the body 2 and the shielding member 9 cannot be made of air-tight materials at the same time. The shielding member 9 can be selected to be staggered or at least partially overlapped with the air...

no. 3 example

[0049] Refer to attached figure 1 , attached Figure 4 and attached Figure 5 The dust collection device 1 and the dust collection device 1a also include a pouring port 11 connecting the outside world with the dust collecting device 1 and the interior of the dust collecting device 1a. The pouring port 11 is arranged on the body 2 and can be closed or opened selectively for pouring and collecting Dust in the dust collector 1a.

[0050] The edge of pouring mouth 11 is provided with the pouring mouth zipper 8 that makes it open or close, is used to open pouring mouth 11 to pour over leaves and dust in dust collecting device 1 or dust collecting device 1a, or in dust collecting device 1 or collecting When the dust device 1a is working, the pouring port 11 is closed, so that leaves and dust are left in the dust collecting device 1 or inside the dust collecting device 1a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com