Fermenter for temperature detection

A technology of fermentation barrel and detection module, applied in the field of fermentation tank, can solve the problems of inaccuracy, inaccurate temperature control, unqualified soy sauce, etc., and achieve the effects of wide collection, easy storage and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

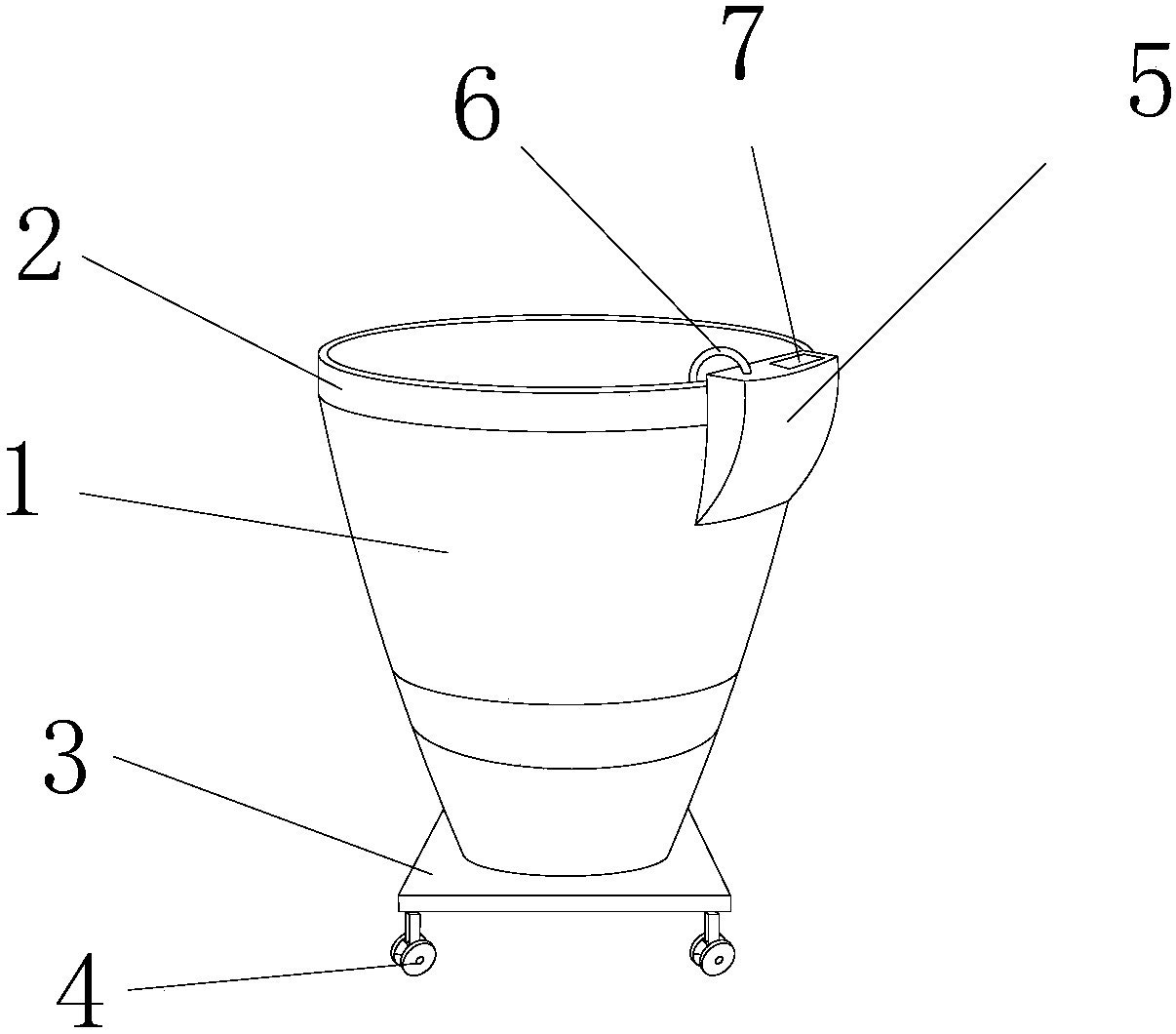

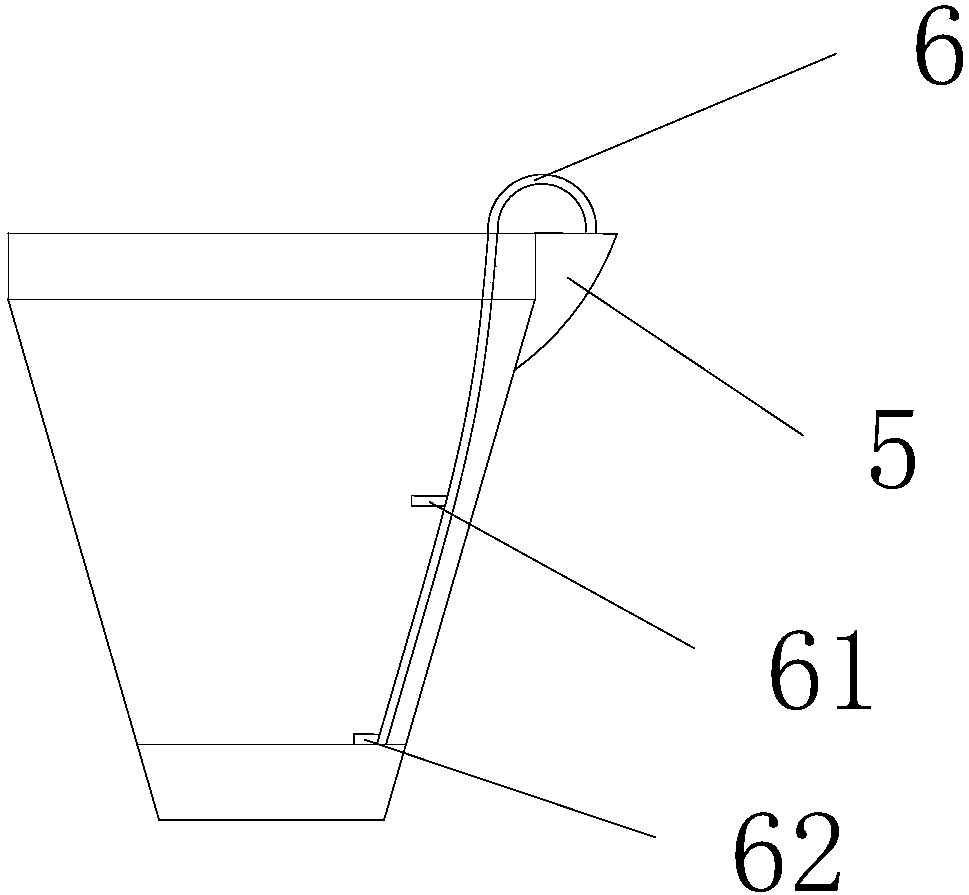

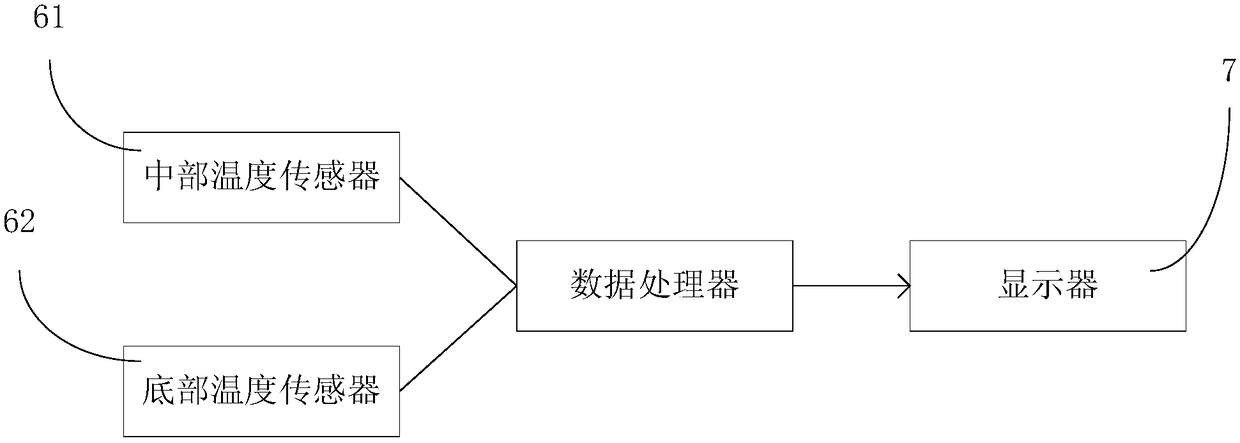

[0025] Such as figure 1 , 2 , 3, a fermenter for temperature detection, including a cylinder body 1, a temperature detection module, the temperature detection module includes a data table 5, a temperature sensor 6, a display 7, the temperature sensor 6 is provided with two, Respectively, the middle temperature sensor 61 arranged on the inner surface of the cylinder body 1, and the bottom temperature sensor 62 arranged on the bottom surface of the cylinder body 1, the middle temperature sensor 61 and the bottom temperature sensor 62 are all electrically connected to the data table 5; The above-mentioned display 7 is arranged on the data station 5, and is used for displaying the data sent by the data station 5. The middle temperature sensor 61 and the bottom temperature sensor 62 collect the temperature of the middle part and the bottom of the cylinder body 1 respectively, and send the data of the temperature to the data processor located in the data table 5, through the calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com