Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem of high gas production, and achieve the effect of high input and output characteristics and low gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

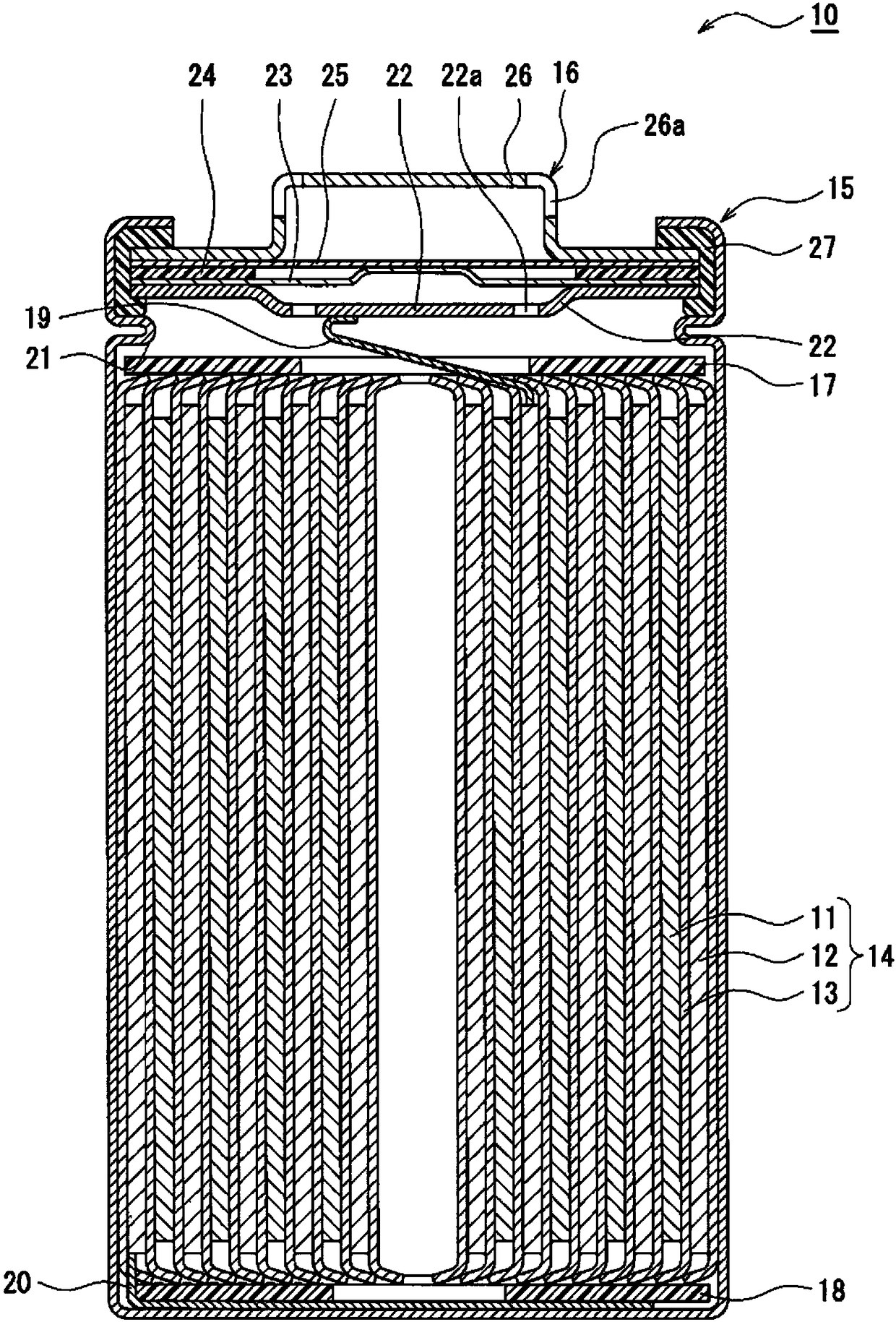

Image

Examples

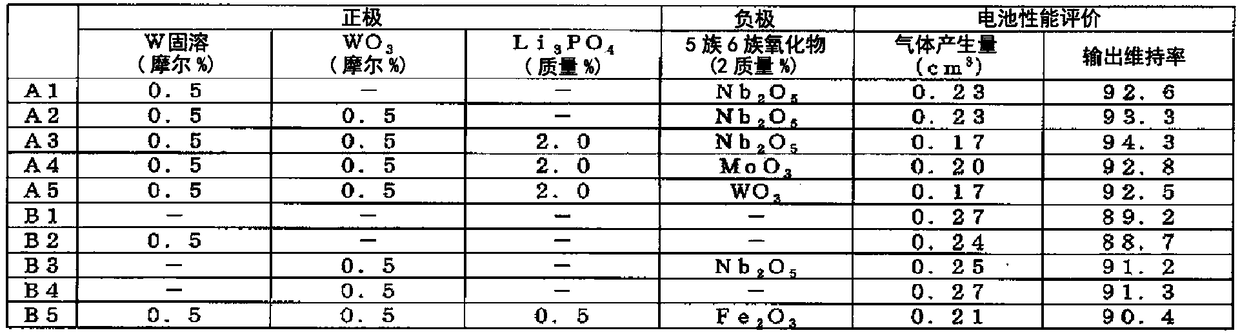

Embodiment 1

[0059] [Production of positive electrode active material]

[0060] [Ni 0.50 co 0.20 mn 0.30 ](OH) 2 The hydroxides shown were calcined to obtain nickel-cobalt-manganese composite oxides. Then, the total amount of Li, Ni, Co, Mn and WO 3 The molar ratio of W in the mixture is 1.2:1:0.005 and lithium carbonate, the above-mentioned nickel-cobalt-manganese composite oxide and tungsten oxide (WO 3 ). The mixture was heat-treated and pulverized at 900°C for 20 hours in an air atmosphere, thereby obtaining Li in which W was solid-dissolved. 1.07 [Ni 0.465 co 0.186 mn 0.279 W 0.005 ]O 2 Lithium transition metal oxide (cathode active material) shown. The obtained composite oxide powder was observed with a scanning electron microscope (SEM), and it was confirmed that unreacted tungsten oxide did not remain.

[0061] [making of positive electrode]

[0062] The above-mentioned positive electrode active material, acetylene black, and polyvinylidene fluoride were mixed at a ma...

Embodiment 2

[0072] The lithium transition metal oxide and tungsten oxide (WO) of Example 1 were mixed using a Hivis Disper mixer (PRIMIX). 3 ), fabricated WO attached on the surface of lithium transition metal oxide 3 positive active material. At this time, metal elements (Ni, Co, Mn, W) other than Li in lithium transition metal oxides and WO 3 The molar ratio of W was mixed in such a way that the ratio was 1:0.005. Added WO when making positive electrode active material 3 A battery A2 was produced in the same manner as in Example 1 except that. It should be noted that, as a result of observing the obtained positive electrode composite material layer by SEM, it was confirmed that tungsten oxide particles with an average particle diameter of 150 nm adhered to the particle surface of the lithium transition metal oxide.

Embodiment 3

[0074] Lithium phosphate (Li 3 PO 4 ) mixture, acetylene black and polyvinylidene fluoride to make positive electrode composite material slurry. Lithium phosphate (Li 3 PO 4 ) was added in an amount of 2% by mass relative to the active material. Added Li when making positive electrode 3 PO 4 A battery A3 was produced in the same manner as in Example 2 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com