Electrode structure for gas spark switch and design method

A technology of gas spark switch and electrode structure, which is applied in the direction of spark gap, spark gap parts, spark gap with auxiliary trigger device, etc., can solve the problem of increasing the number of initial electrons and discharge channels, low operating voltage, mechanical structure and working Circuit complexity and other issues, to achieve the effect of improving trigger breakdown performance, increasing the number of discharge channels, and improving trigger breakdown performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

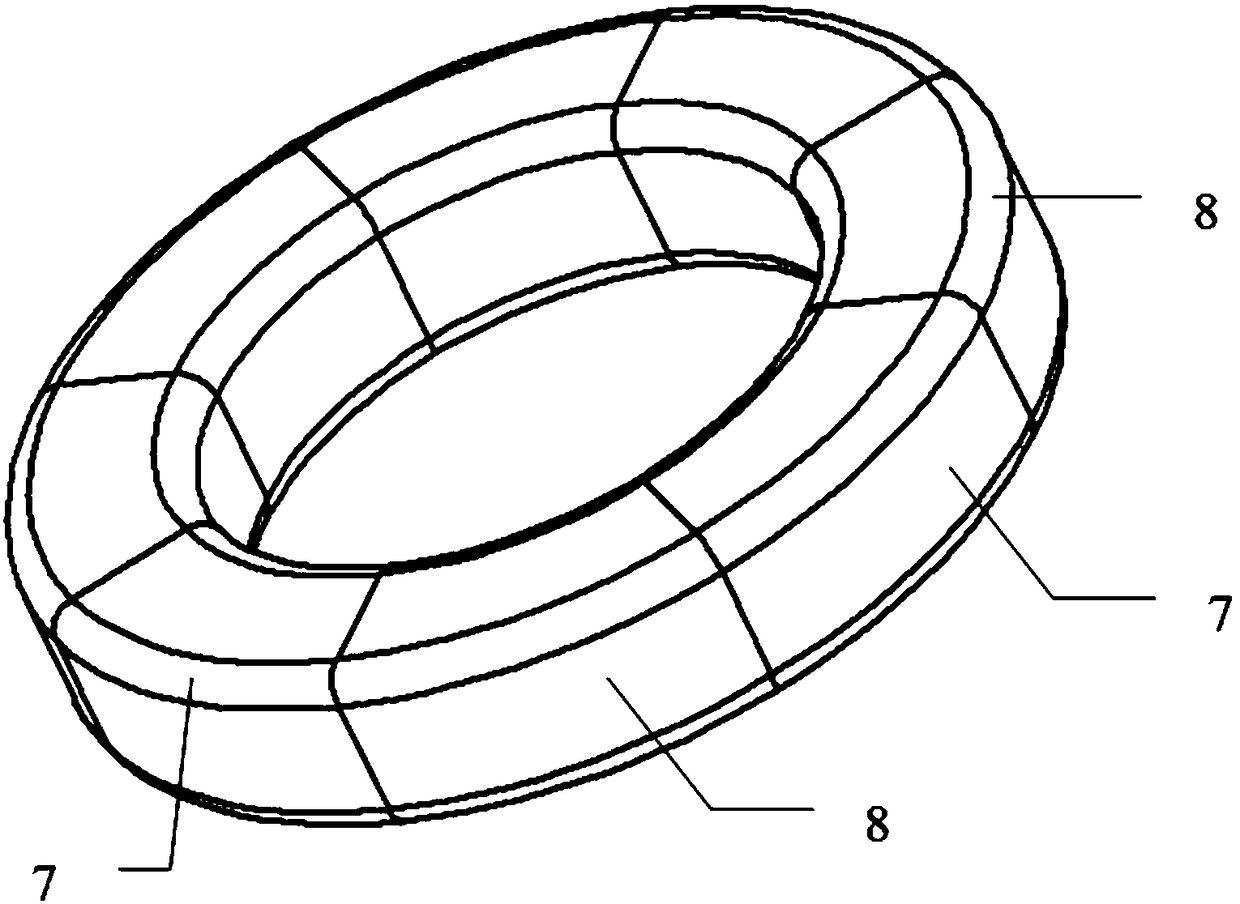

[0059] Such as figure 1 As shown, a ring-shaped combined material electrode structure is composed of 4 low work function electrode material blocks 7 and 4 high work function electrode material blocks 8, and the analysis of stainless steel, brass, tungsten copper and The physical properties of graphite and other electrode materials are compared with their work function. It is found that the equivalent work function of tungsten copper and graphite is quite different. These two materials with large difference in electron emission efficiency are selected as the combined material for making electrodes. . Experimentally measure the number of discharge channels formed by the gas gap formed by the electrodes of two materials during pulse voltage discharge. Graphite has a high electron emission efficiency, and the average number of discharge channels formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com