Lithium manganese iron phosphate-based composite positive electrode material and preparation method thereof

A composite positive electrode material, lithium manganese iron phosphate technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor electrical conductivity, etc., to solve the problems of poor electrical conductivity, good cycle performance, and high energy density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Correspondingly, combined with figure 1 The embodiment of the present invention also provides a method for preparing a lithium iron manganese phosphate-based composite cathode material, which includes the following steps:

[0043] S01. Provide crude nickel cobalt manganese oxide and / or nickel cobalt lithium aluminate, dispersed in a solvent for ball milling, and crushed the crude lithium cobalt manganate and / or nickel cobalt aluminate to obtain a particle size of 200 -500nm lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate particles; provide lithium manganese iron phosphate particles, and obtain lithium iron manganese phosphate microspheres with a secondary particle size of 5-20um through spray drying;

[0044] S02 Weigh lithium nickel cobalt manganese oxide and / or lithium nickel cobalt aluminate particles and lithium iron manganese phosphate microspheres according to the raw material ratio of the foregoing lithium manganese iron phosphate-based composite...

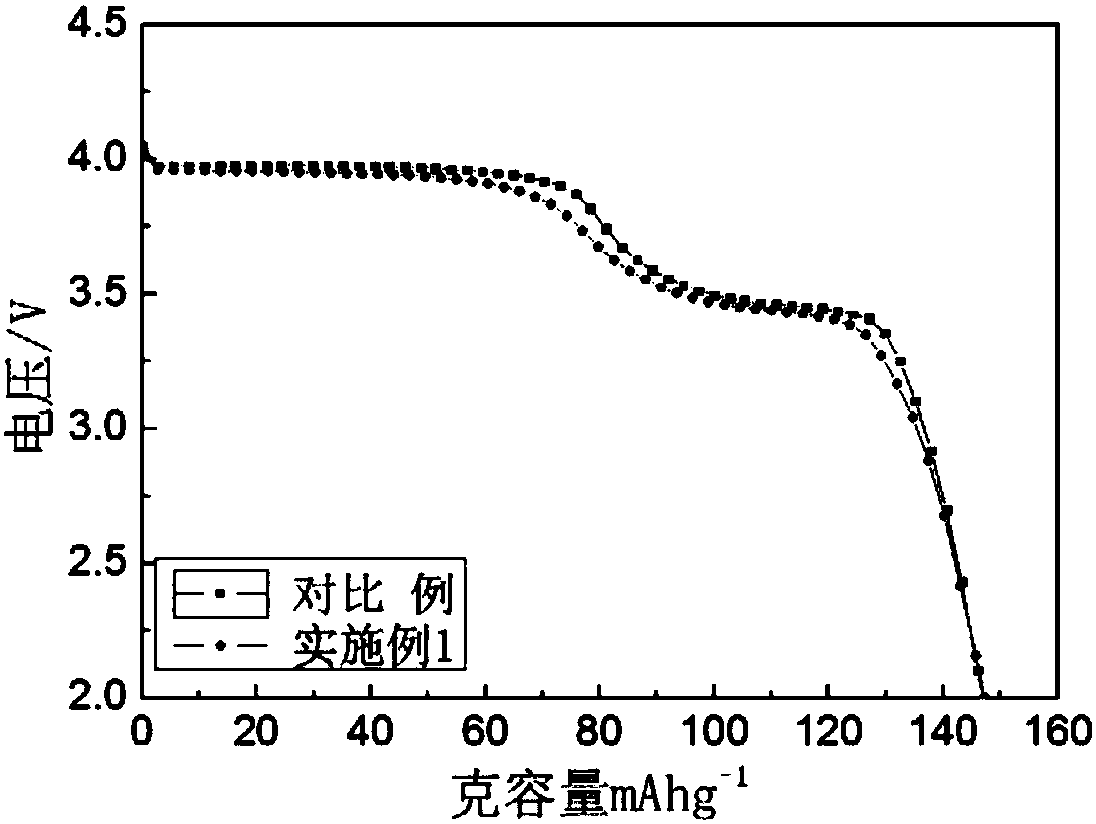

Embodiment 1

[0057] A method for preparing lithium iron manganese phosphate-based composite cathode material includes the following steps:

[0058] S11. Provide crude nickel cobalt manganese oxide and / or nickel cobalt lithium aluminate, dispersed in a solvent for ball milling, ball milling the spherical ternary material into small particles of nickel and cobalt with a primary particle size of 200-500nm Lithium manganate and / or lithium nickel cobalt aluminate; provide lithium manganese iron phosphate particles, and obtain spherical granular lithium iron manganese phosphate with a secondary particle size of 5-20um through spray drying;

[0059] S12. Put the processed lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate and lithium iron manganese phosphate according to the mass ratio of lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate to lithium iron manganese phosphate as 1: The ratio of 99 is dispersed in the solvent to form a mixed liquid;

[0060] S13. Af...

Embodiment 2

[0063] A method for preparing lithium iron manganese phosphate-based composite cathode material includes the following steps:

[0064] S21. Provide crude nickel cobalt manganese oxide and / or nickel cobalt lithium aluminate, dispersed in a solvent for ball milling, ball milling the spherical ternary material into small particles of nickel and cobalt with a primary particle size of 200-500nm Lithium manganate and / or lithium nickel cobalt aluminate; provide lithium manganese iron phosphate particles, and obtain spherical granular lithium iron manganese phosphate with a secondary particle size of 5-20um through spray drying;

[0065] S22. Put the treated lithium nickel cobalt manganese oxide and / or lithium nickel cobalt aluminate and lithium iron manganese phosphate according to the mass ratio of lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate to lithium iron manganese phosphate as 30: 70% dispersed in the solvent to form a mixed liquid;

[0066] S23. After the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com