Representative measuring point feature parameter determining method for smoke gas ingredient concentration whole cross section measurement

A technology of characteristic parameters and determination methods, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of uneven concentration distribution, not considering the real distribution characteristics of gas components in the whole section, to overcome measurement errors and improve measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

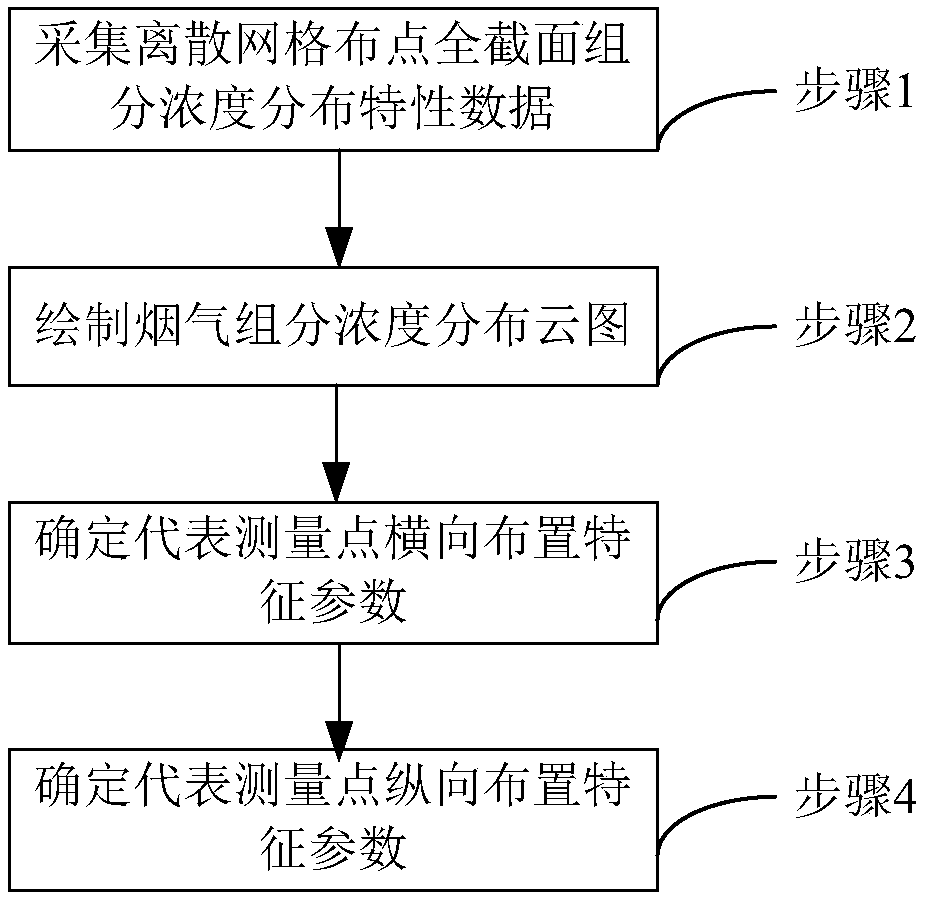

[0026] like figure 1 As shown, what is described in the embodiment of the present invention is a method for determining characteristic parameters of representative measurement points for full-section measurement of smoke component concentration, the method comprising the following steps:

[0027] Step 1. Use the flue gas component measuring instrument to measure the discrete distribution characteristics of the flue gas component concentration in the entire flue section to be tested under the fixed load condition based on the discrete grid point distribution method; this implementation In this example, the existing flue gas component measuring instrument is used to measure the concentration of flue gas components in the section of the flue to be tested. The discrete distribution characteristics of the concentration of the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com