Combination prefabricated shear wall with vertical ECC energy consumption belts and manufacturing method thereof

A combined assembly and shear wall technology, applied in the field of building earthquake resistance, can solve problems such as the application of combined shear wall of ECC cast body and other problems that have not yet been seen, and achieve the effect of improving stiffness, reducing construction cost, and reducing fire and rust treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

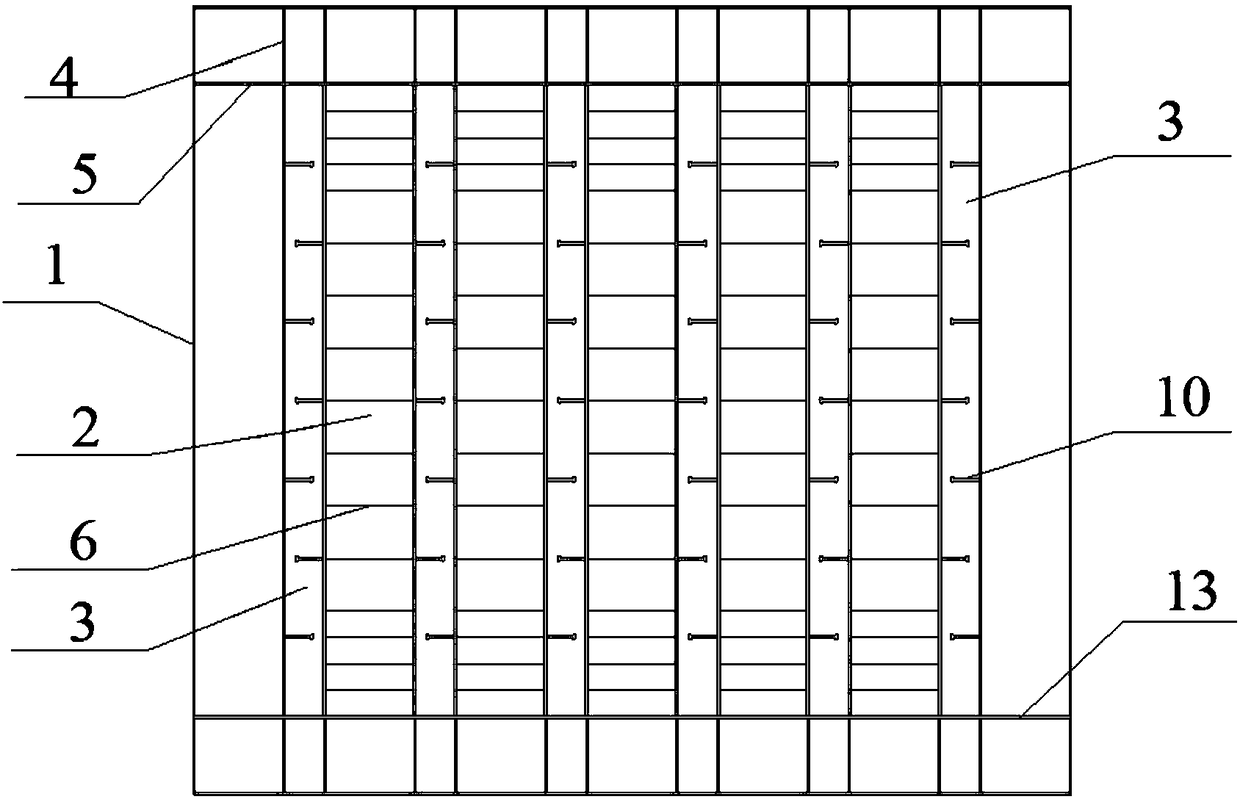

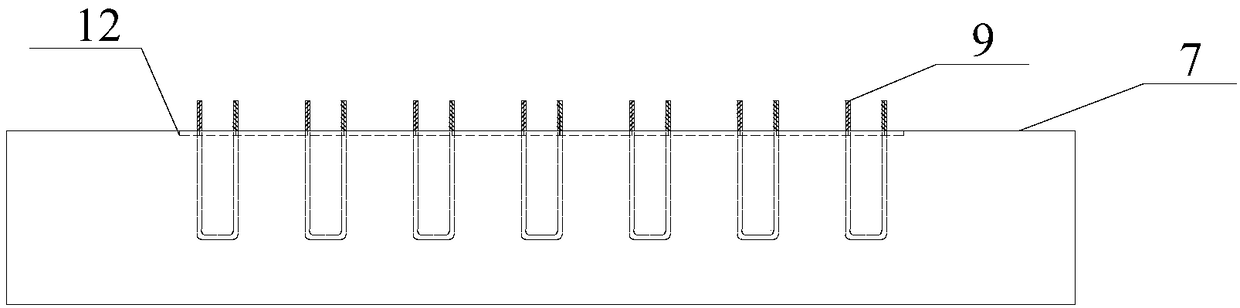

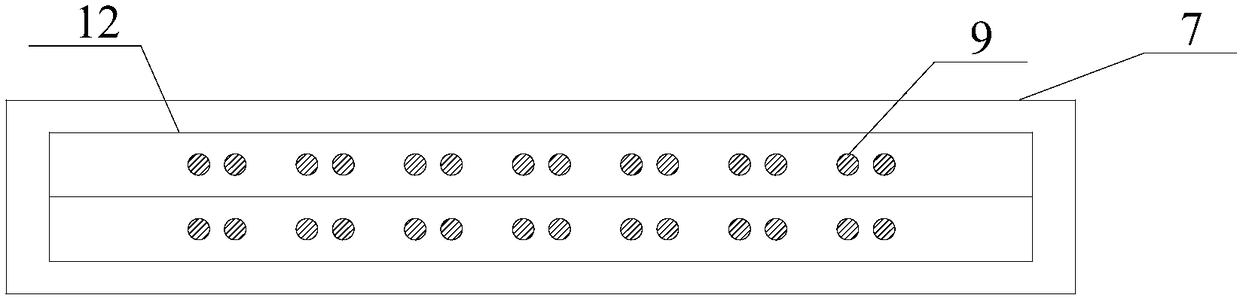

[0036] The invention provides a combined assembled shear wall with a vertical ECC energy dissipation belt, one structural unit of which includes an upper frame beam 8, a lower frame beam 7, a steel tube concrete frame column 1 and a combined shear wall. Such as figure 1 , Figure 5 , Image 6 with Figure 7 As shown, the CFST frame column 1 is composed of a single steel pipe and self-compacting concrete filled in the entire space in the steel pipe. Two CFST frame columns 1 are arranged at the left and right ends of the composite shear wall, parallel to each other inside the composite shear wall. A plurality of partially filled composite core columns 2 spaced apart from each other are arranged in the direction of the steel tube concrete frame column 1 . The partially filled composite core column 2 includes H-shaped steel and ordinary concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com