Phase change heat collecting-heat dissipation wall system operating under full working conditions

A heat dissipation wall and full working condition technology, applied in the field of phase change heat collection-radiation wall system, can solve the problems of low heat storage and discharge rate, poor thermal insulation performance, and reduced utilization rate of stored heat in phase change heat collection and heat storage walls , to achieve the effect of reducing the incoming of solar radiant heat, good heat preservation and heat insulation, and reducing the loss of radiant heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

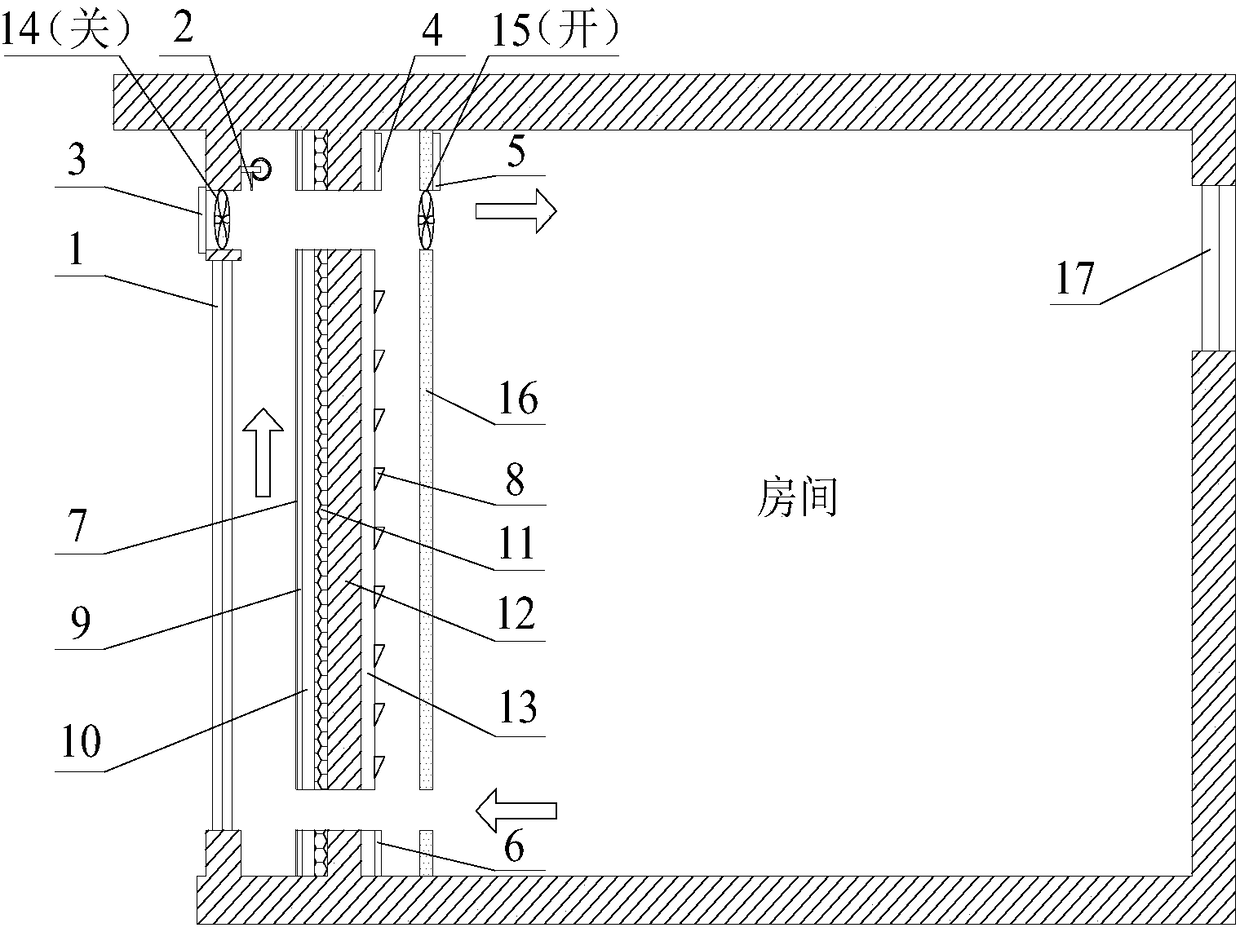

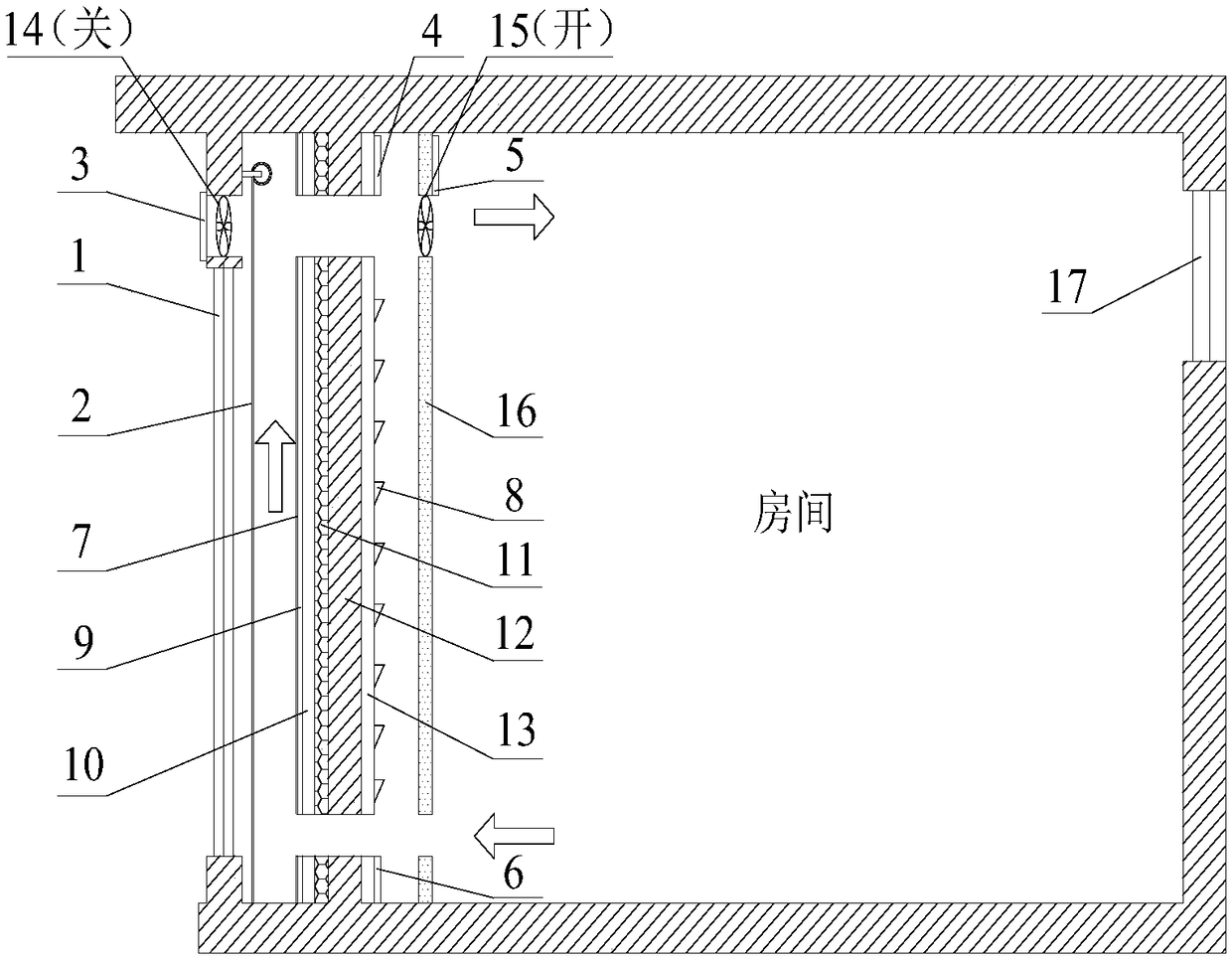

[0036] refer to Figure 1(a)-Figure 1(d) As shown, the present invention proposes a phase-change heat collection-radiation wall system operated under full working conditions, including a glass cover plate 1 arranged on the window of the room (in this embodiment, on the window opposite to the north-facing window 17) A thermal storage wall 12 is provided inside the glass cover 1, and a decorative panel 16 is provided inside the thermal storage wall 12; the top opening of the glass cover 1 communicates with the outside, and the top and bottom openings of the thermal storage wall 12 form Double-chamber, the top and bottom openings of the decorative plate 16 communicate with the room, and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com