Special enzyme for hydrolyzing animal protein and preparation method thereof

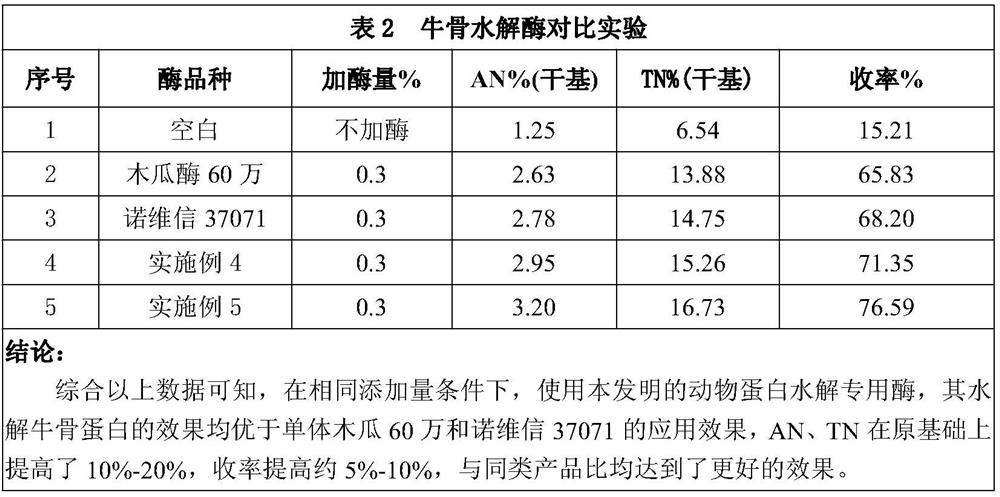

A technology for animal protein hydrolysis and special enzyme, applied in the field of special enzyme for animal protein hydrolysis and its preparation, can solve the problems of serious corrosion of processing equipment, residual chemical components, loss of nutrients, etc., and achieve a mellow and natural flavor, high degree of hydrolysis, and improved umami effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A special enzyme for animal protein hydrolysis, in weight percentage, including the following raw materials: papain 8%, bromelain 8%, nuclease 4%, flavor enzyme 8%, salt 18%, trehalose 4%, food grade glucose 35%;

[0028] The preparation method of the special enzyme for hydrolyzing animal protein comprises the following steps:

[0029] (1) Extract papain: collect papaya pulp, mix papaya pulp and water according to the weight ratio of 1:30, after the papaya pulp is fully dissolved, filter with plate frame to obtain crude enzyme liquid, then filter through organic membrane to remove Bacteria and ultra-low molecular film concentration, and finally spray-dried to obtain papain, and papain was crushed into 85 mesh fine powder for later use;

[0030] (2) Extract bromelain: mix pineapple juice and water evenly according to the weight ratio of 1:5. After fully dissolving, extract for 10 minutes to obtain crude enzyme liquid, then filter and sterilize through organic membrane, ...

Embodiment 2

[0035] A special enzyme for animal protein hydrolysis, in weight percentage, including the following raw materials: papain 9%, bromelain 9%, nuclease 5%, flavor enzyme 9%, salt 19%, trehalose 5%, food-grade glucose 38%;

[0036] The preparation method of the special enzyme for hydrolyzing animal protein comprises the following steps:

[0037] (2) extract papain: collect papaya pulp, mix papaya pulp and water according to the weight ratio of 1:30, after papaya pulp is fully dissolved, filter with plate frame to obtain crude enzyme liquid, then filter through organic membrane to remove Bacteria and ultra-low molecular film concentration, and finally spray-dried to obtain papain, and papain was crushed into 85 mesh fine powder for later use;

[0038] (2) Extract bromelain: mix pineapple juice and water evenly according to the weight ratio of 1:5. After fully dissolving, extract for 10 minutes to obtain crude enzyme liquid, then filter and sterilize through organic membrane, and ...

Embodiment 3

[0043] A special enzyme for hydrolyzing animal protein, with the unit of weight percent, including the following raw materials: papain 10%, bromelain 10%, nuclease 5%, flavor enzyme 10%, salt 20%, trehalose 5%, food-grade glucose 40%;

[0044]The preparation method of the special enzyme for hydrolyzing animal protein comprises the following steps:

[0045] (1) Extraction of papain: collect papaya pulp, mix papaya pulp and water evenly according to the weight ratio of 1:30, after the papaya pulp is fully dissolved, filter it with a plate frame to obtain a crude enzyme solution, and then filter it through a membrane to sterilize , ultra-low molecular film concentration, and finally spray drying to obtain papain, and papain is pulverized into 85 mesh fine powder for subsequent use;

[0046] (2) Extraction of bromelain: Mix pineapple juice and water evenly in a weight ratio of 1:5. After fully dissolving, extract for 10 minutes to obtain a crude enzyme solution, which is then ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com