Method for extracting active ingredients in threonine fermentation concentrate

A technology for fermentation concentrate and active ingredients, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as waste of resources, loss of economic benefits, environmental pollution, etc., to reduce the discharge of harmful substances and improve the economy Benefit, deal with the effect of efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

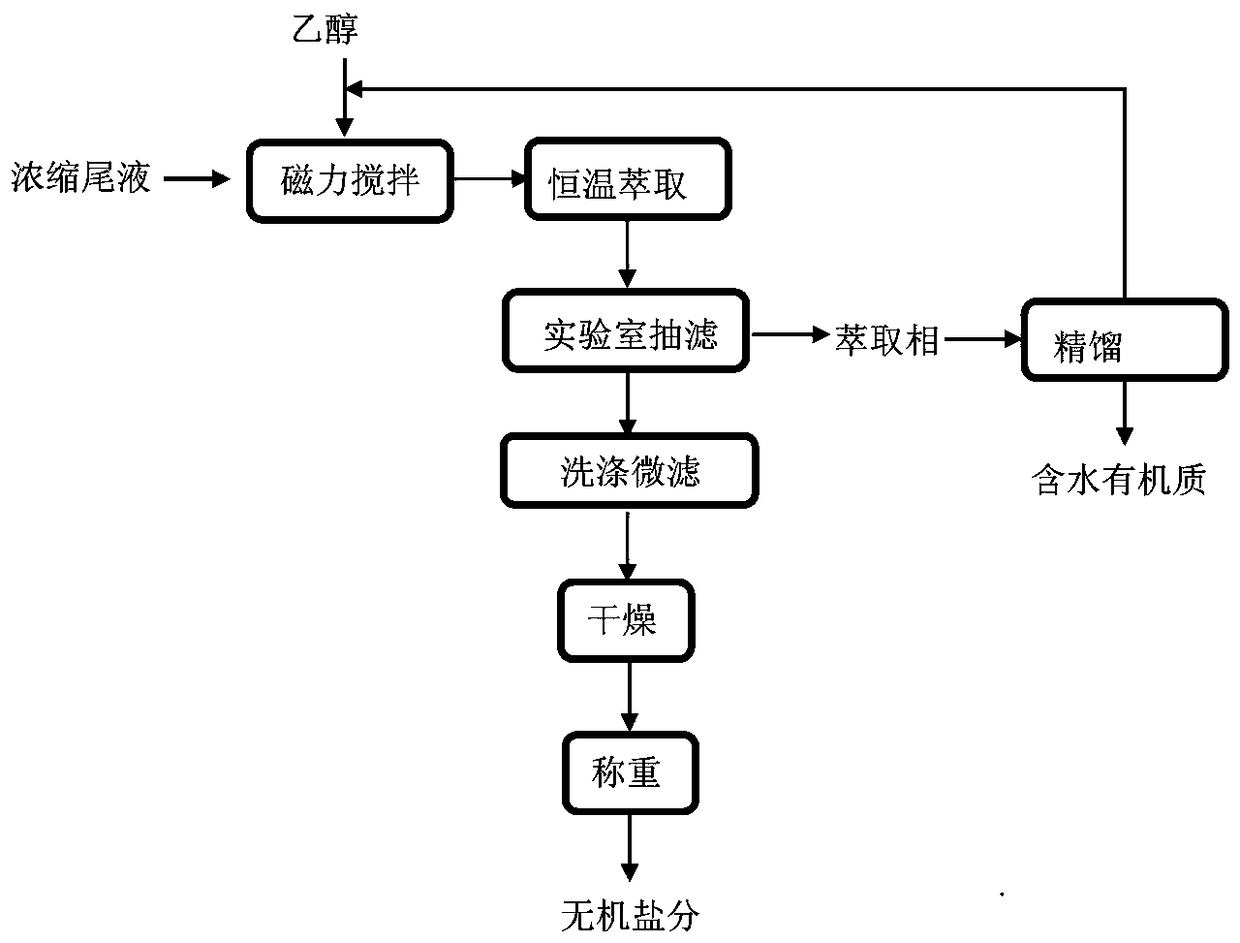

Method used

Image

Examples

Embodiment Construction

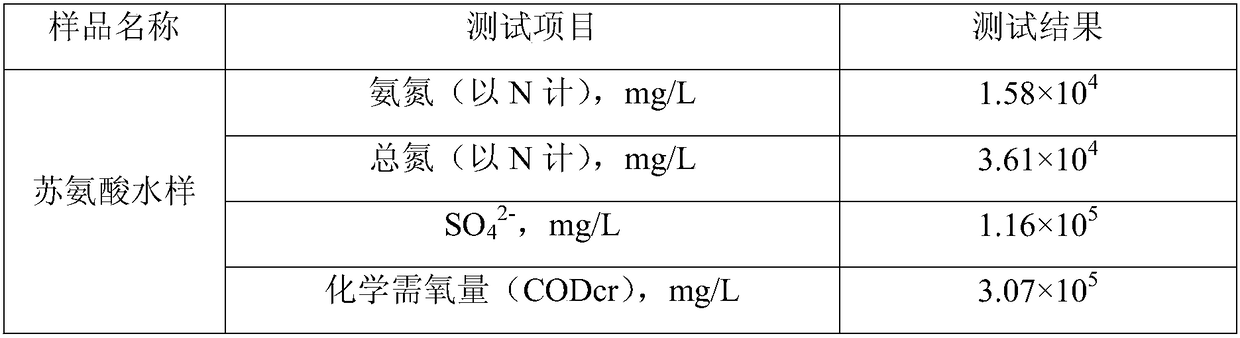

[0015] 1. Sample analysis

[0016] The threonine fermentation concentrate used in this example is the concentrated tail liquid obtained by extracting threonine from crops through microbial fermentation, and then undergoing multi-effect evaporation. Accompanied by a pungent strong fragrance. According to on-site investigation and analysis of test results, the concentrated solution is mainly composed of threonine, soluble protein, carbohydrates and inorganic salts, with a solid content of 40% and a water content of 60%. SS is 13%, PH=5.9, showing weak acidity, and the test results are shown in Table 1.

[0017] Table 1

[0018]

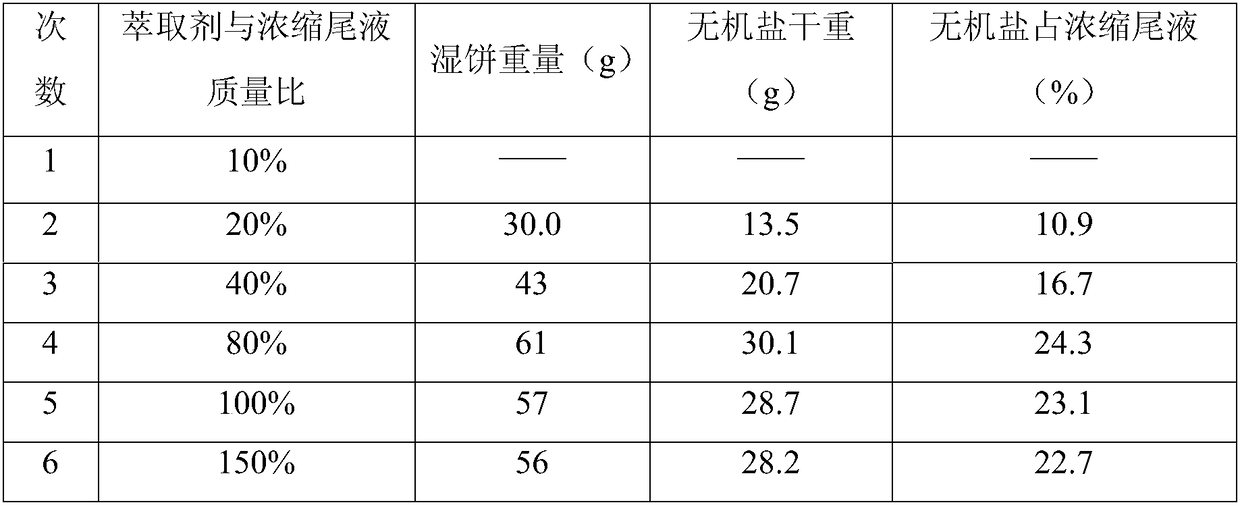

[0019] 2. Determine the optimal scheme for the extraction of active ingredients in the concentrated tail liquid of threonine fermentation

[0020] 2.1 Determine the optimal mass ratio of extractant and concentrated tail liquid

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com