Esterification production technology of methyl acetoacetate

A technology for the production of methyl acetoacetate, applied in the preparation of carboxylic acid esters, organic chemistry, chemical instruments and methods, etc., can solve the problems of difficult control of reaction temperature, long reaction time, low conversion rate, etc., and achieve the goal of eliminating overheating Phenomenon, high synthesis rate, effect of increasing reaction temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

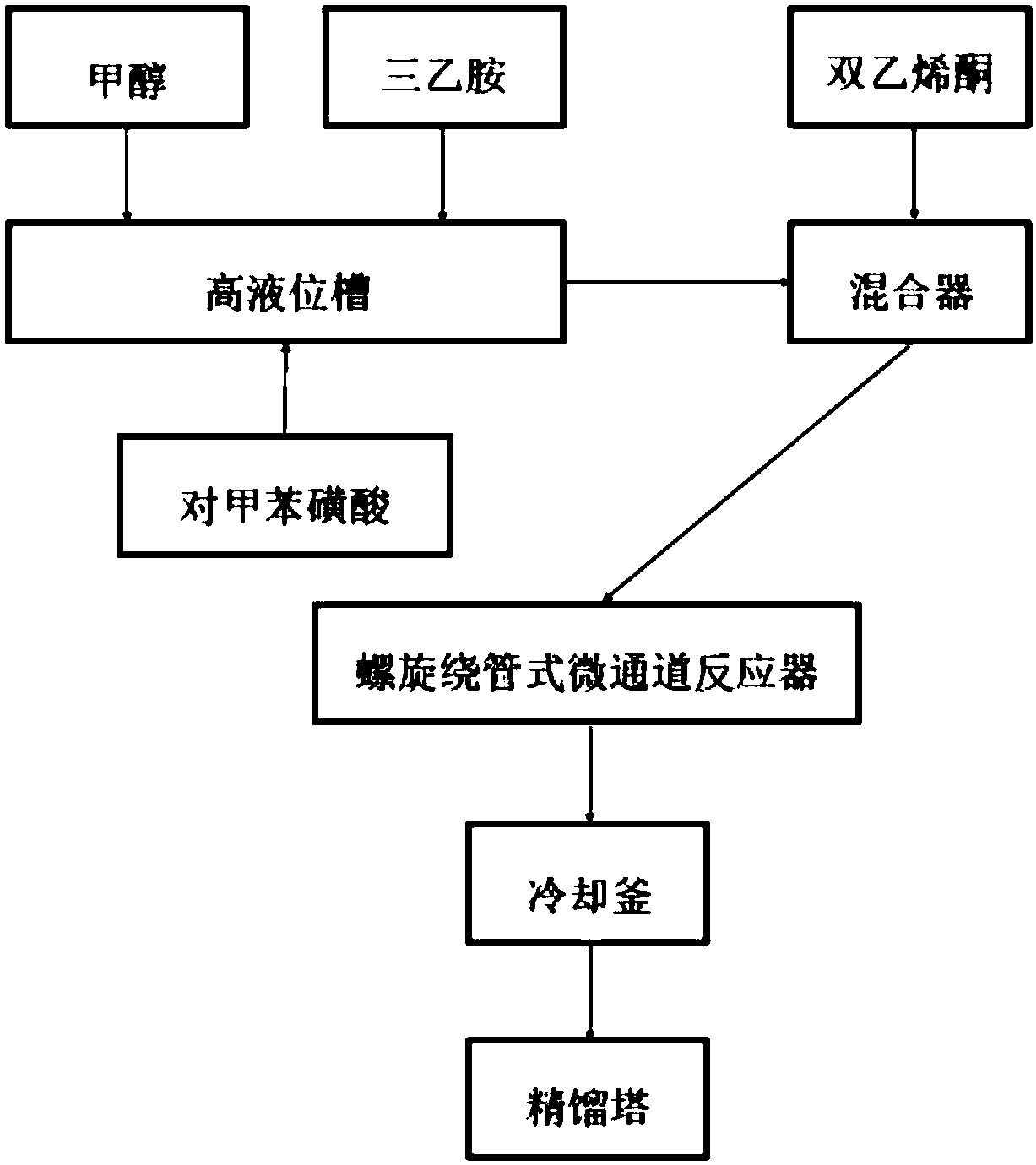

Image

Examples

Embodiment 1

[0035] 1. Accurately add 29.2kg (36.804L) of methanol and 244g of triethylamine into the melting pot, and start the stirring pump. Open the feeding valve and send the mixed material in the melting tank to the high liquid level tank.

[0036] 2. Add 6.1g of p-toluenesulfonic acid into the high liquid level tank, mix well and send it into the mixer; 140 900m capillary tubes are used in the mixer.

[0037] 3. Accurately batch 64.956L diketene, open the feeding valve, send diketene into the mixer, and mix thoroughly.

[0038] 4. Turn on the circulating pump, and adjust the temperature of the constant temperature water in the spiral-wound microchannel reactor to 85°C. The mixture in the mixer was sent to a spiral-wound tube microchannel reactor for esterification reaction, and was retained for 10 min at a pressure of 3 MPa in the tube.

[0039] 5. After the reaction, put the material into the cooling kettle, open the brine to cool down to 40°C, and cool for 1 hour.

[0040] 6. S...

Embodiment 2

[0042] 1. Accurately add 73.608L of methanol and 488g of triethylamine into the melting pot, and start the stirring pump. Open the feeding valve and send the mixed material in the melting tank to the high liquid level tank.

[0043] 2. Add 12.2g of p-toluenesulfonic acid into the high liquid level tank, mix well and send it into the mixer; 160 900m capillary tubes are used in the mixer.

[0044] 3. Accurately batch 129.912L diketene, open the feeding valve, send diketene into the mixer, and mix thoroughly.

[0045] 4. Turn on the circulating pump, and adjust the temperature of the constant temperature water in the spiral-wound microchannel reactor to 80°C. The mixture in the mixer was sent to a spiral-wound tube microchannel reactor for esterification reaction, and was retained for 60 min at a pressure of 3 MPa in the tube.

[0046] 5. After the reaction, put the material into the cooling kettle, open the brine to cool down to 45°C, and cool for 4 hours.

[0047] 6. Send th...

Embodiment 3

[0049] 1. Accurately add 18.402L of methanol and 122g of triethylamine into the melting pot, and start the stirring pump. Open the feeding valve and send the mixed material in the melting tank to the high liquid level tank.

[0050] 2. Add 3.05g of p-toluenesulfonic acid into the high liquid level tank, mix well and send it into the mixer; 140 600m capillary tubes are used in the mixer.

[0051] 3. Accurately batch 32.478L diketene, open the feeding valve, send diketene into the mixer, and mix thoroughly.

[0052]4. Turn on the circulation pump, and adjust the temperature of the constant temperature water in the spiral-wound microchannel reactor to 100°C. The mixture in the mixer was sent to a spiral-wound tube microchannel reactor for esterification reaction, and was kept for 5 minutes under the pressure of 3 MPa in the tube.

[0053] 5. After the reaction, put the material into the cooling kettle, open the brine to cool down to 0°C, and cool for 30 minutes.

[0054] 6. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com