A kind of phase change negative ion glass magnesium artificial stone plate and its manufacturing method

An artificial slate and negative ion technology, applied in the field of building materials, can solve problems such as single function, insufficient mechanical properties, poor energy saving and environmental protection effects, and achieve the effect of improving the natural environment and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

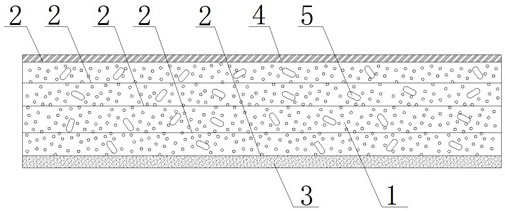

[0039] A phase-change negative ion glass magnesium artificial stone plate is characterized in that: it includes a cementitious material layer 1, a glass fiber mesh cloth layer 2 embedded in the cementitious material layer 1, a natural color surface layer 3 at the bottom of the artificial stone plate, and a natural color surface layer located at the artificial stone plate. Sand the top coat 4.

[0040]The cementitious material layer 1 includes the following raw materials in parts by weight: 2 parts of blast furnace slag, 1 part of magnesium sulfate solution, 3 parts of lightly burned magnesium oxide powder, 1 part of modifier, 1 part of phase change material capsule and tourmaline powder 0.5 servings.

[0041] The natural color surface layer 3 and the sanding surface layer 4 include the following raw materials in parts by weight: 2 parts of blast furnace slag, 1 part of magnesium sulfate solution, 3 parts of lightly burned magnesium oxide powder, 1 part of modifier, 2 parts of ...

Embodiment 2

[0054] Its difference with embodiment 1 is:

[0055] The cementitious material layer 1 includes the following raw materials in parts by weight: 2 parts of blast furnace slag, 3 parts of magnesium sulfate solution, 1 part of lightly burned magnesium oxide powder, 2 parts of modifier, 2 parts of phase change material capsule and tourmaline powder 0.5 servings.

[0056] The natural color surface layer 3 and the sanding surface layer 4 include the following raw materials in parts by weight: 2 parts of blast furnace slag, 3 parts of magnesium sulfate solution, 1 part of magnesium oxide lightly burned powder, 2 parts of modifier, 3 parts of dolomite powder and 0.5 parts of tourmaline powder.

[0057] The Baume degree of described magnesium sulfate solution is 35 ° of Be.

[0058] The thickness of the cementitious material layer 1 is 20mm, and there are 6 layers of glass fiber mesh cloth.

[0059] The capsule skin of the phase-change material capsule is made of acrylic resin, and ...

Embodiment 3

[0063] Its difference with embodiment 1 is:

[0064] The cementitious material layer 1 includes the following raw materials in parts by weight: 3 parts of blast furnace slag, 2 parts of magnesium sulfate solution, 2 parts of lightly burned magnesium oxide powder, 1 part of modifier, 1 part of phase change material capsule and tourmaline powder 0.5 servings.

[0065] The natural color surface layer 3 and the sanding surface layer 4 include the following raw materials in parts by weight: 4 parts of blast furnace slag, 3 parts of magnesium sulfate solution, 3 parts of lightly burned magnesium oxide powder, 1 part of modifier, 2 parts of dolomite powder and 0.5 parts of tourmaline powder.

[0066] The Baume degree of described magnesium sulfate solution is 30 ° of Be.

[0067] The thickness of the cementitious material layer 1 is 40 mm, and there are 10 layers of glass fiber mesh cloth.

[0068] The capsule skin of the phase-change material capsule is made of acrylic resin, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com