Method of producing high-strength artificial rutile from ilmenite

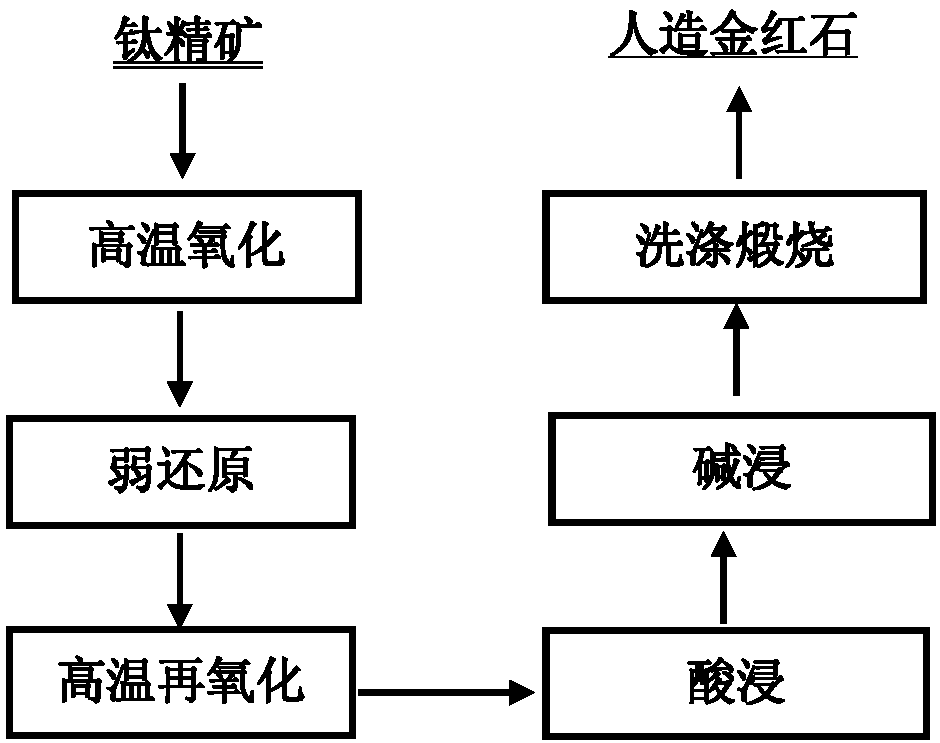

A technology of artificial rutile and ilmenite, applied in chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problems of easy pulverization and low strength of artificial rutile, achieve low proportion of fine powder, realize large-scale continuous production, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment selects the main component of ilmenite: TiO 2 : 46.76%, FeO: 35.59%, Fe 2 o 3 : 5.12%, MgO: 6.62%, CaO: 1.03%, SiO 2 : 4.56%, Al 2 o 3 : 1.26%; its particle size distribution is between 60 and 200 meshes, and the average particle size is 185 μm; the specific preparation steps are as follows:

[0062] A, the ilmenite is oxidized and roasted at 1000° C. for 1 hour in an air atmosphere in a fluidized bed to obtain an oxidized ore with an oxidation rate of 95%;

[0063] B. The oxidized ore is reduced and roasted at 750° C. for 1 hour under coke oven gas in a fluidized bed to obtain a reduced ore with a reduction rate of 92%;

[0064] C. The reduced ore is oxidized and roasted at 1000° C. for 0.2 h in an air atmosphere in a fluidized bed to obtain a re-oxidized ore with an oxidation rate of 87%;

[0065] D, leaching the reoxidized ore with 20% by weight hydrochloric acid in a reactor with strong stirring (500r / min) with a liquid-solid ratio of 4:1 (L / kg...

Embodiment 2

[0069] This embodiment selects the main component of ilmenite: TiO 2 : 47.8%, FeO: 37.81%, Fe 2 o 3 : 3.66%, MgO: 6.28%, CaO: 0.83%, SiO 2 : 2.32%, Al 2 o 3 : 1.23%; its particle size distribution is between 60 and 200 meshes, and the average particle size is 194 μm; the specific preparation steps are as follows:

[0070] A, the ilmenite is oxidized and roasted at 950° C. for 1.5 hours in an air atmosphere in a fluidized bed to obtain an oxidized ore with an oxidation rate of 93%;

[0071] B. The oxidized ore is reduced and roasted at 800°C for 0.5h under coke oven gas in a fluidized bed to obtain a reduced ore with a reduction rate of 91%;

[0072] C. The reduced ore is oxidized and roasted at 950° C. for 0.3 h under an air atmosphere in the fluidized bed to obtain a re-oxidized ore with an oxidation rate of 82%;

[0073] D, leaching the reoxidized ore with 20% by weight hydrochloric acid in a flask with strong stirring (500r / min) with a liquid-solid ratio of 4:1 (L / kg)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com