Anti-slip glass processing process

A processing technology and glass technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of increased production costs, little improvement of economic efficiency of enterprises, low recycling prices, etc., to avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of non-slip glass processing technology, is characterized in that, comprises following processing step:

[0032] (1) The waste ultra-clear glass is crushed into glass powder by glass crushing equipment, and the average particle size of the glass powder is less than 8nm;

[0033] (2) Mix glass powder, fluorescent powder, and silica gel particles to form a non-slip material, stir and mix thoroughly, and mix according to the following mass parts, wherein, glass powder is 30 parts, phosphor powder is 8 parts, aromatic particles are 4 parts, silica gel particles are 5 parts, the fragrance particles are flower fragrance particles, and the average particle size of the silica gel particles is less than 20nm;

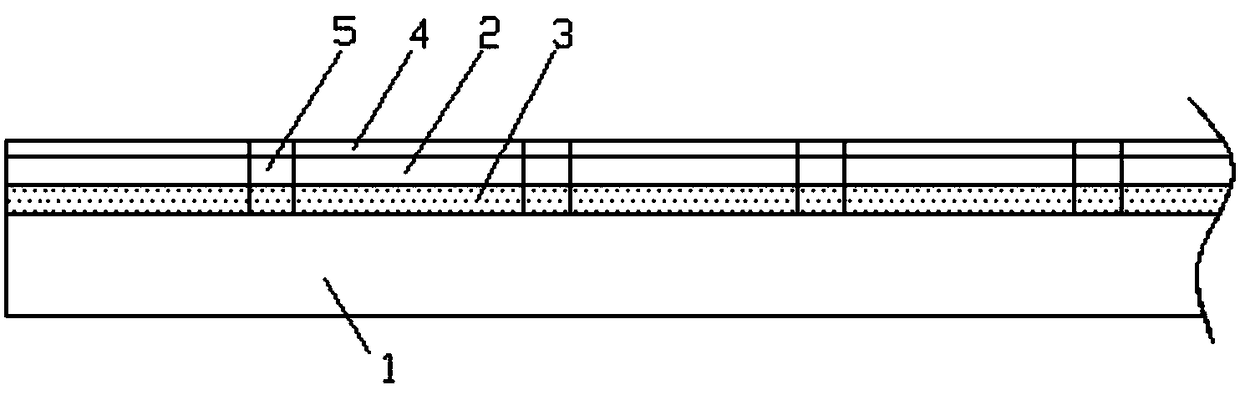

[0034] (3) Cleaning and drying one side surface of the glass 1 to form a clean surface, and the glass is tempered glass;

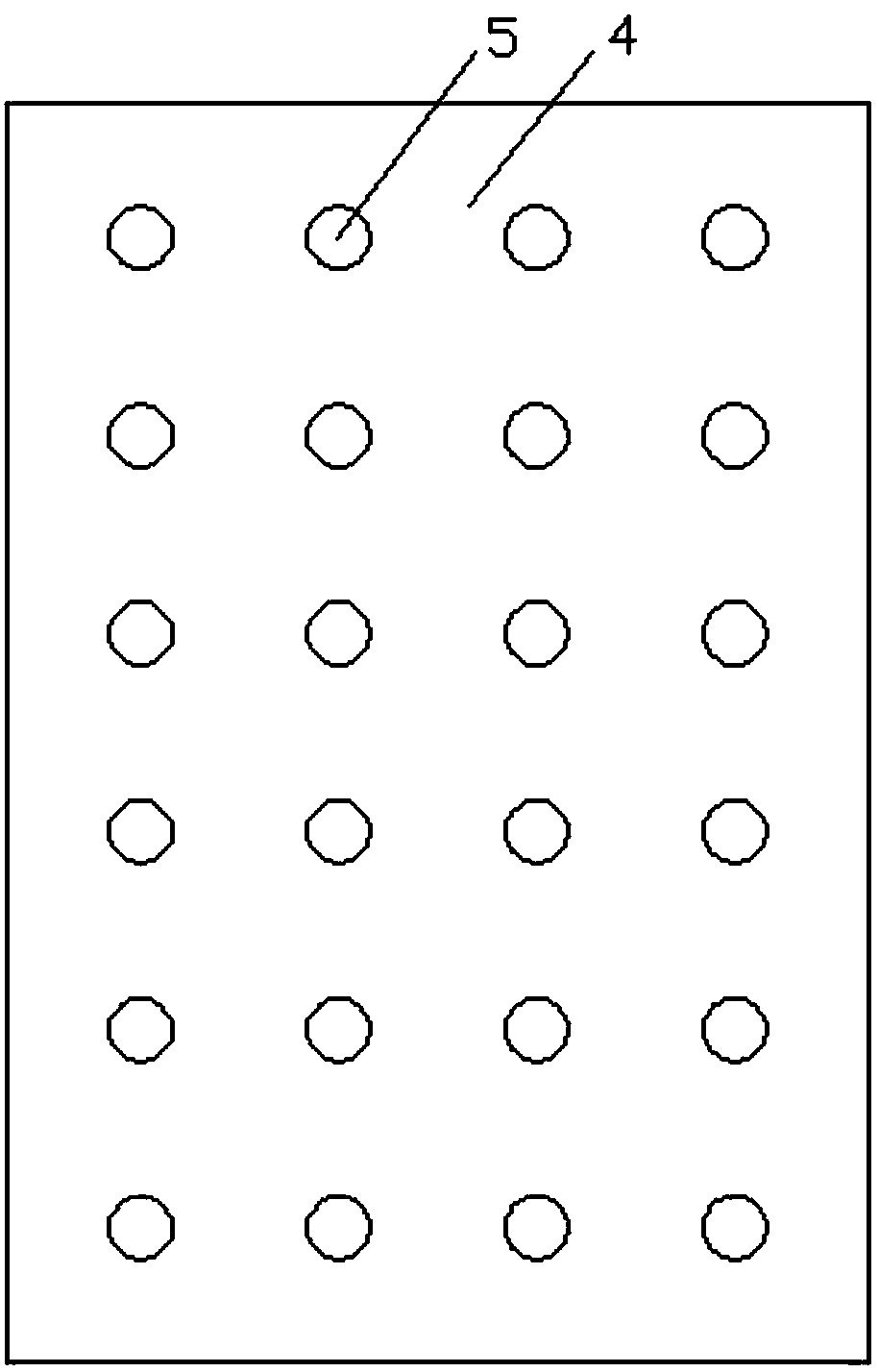

[0035] (4) Cover the clean surface of the glass with a cover plate 2 with a hollow pattern, the hollow pattern 5 is any design style in irreg...

Embodiment 2

[0043] A kind of non-slip glass processing technology, is characterized in that, comprises following processing step:

[0044] (1) The waste ultra-clear glass is crushed into glass powder by glass crushing equipment, and the average particle size of the glass powder is less than 8nm;

[0045] (2) Mix glass powder, fluorescent powder, and silica gel particles to form a non-slip material, stir and mix thoroughly, and mix according to the following mass parts, wherein, glass powder is 20 parts, phosphor powder is 6 parts, aromatic particles are 2 parts, silica gel particles are 2 parts, the fragrance particles are flower fragrance particles, and the average particle size of the silica gel particles is less than 20nm;

[0046] (3) Clean and dry one side of the glass to form a clean surface, and the glass is tempered glass;

[0047] (4) Cover the clean surface of the glass with a cover plate with a hollow pattern. The hollow pattern is any design style among irregular geometric fi...

Embodiment 3

[0055] A kind of non-slip glass processing technology, is characterized in that, comprises following processing step:

[0056] (1) The waste ultra-clear glass is crushed into glass powder by glass crushing equipment, and the average particle size of the glass powder is less than 8nm;

[0057] (2) Mix glass powder, fluorescent powder, and silica gel particles to form a non-slip material, stir and mix thoroughly, and mix according to the following mass parts, wherein, glass powder is 25 parts, phosphor powder is 7 parts, aromatic particles are 3 parts, silica gel particles are 3 parts, the fragrance particles are flower fragrance particles, and the average particle size of the silica gel particles is less than 20nm;

[0058] (3) Clean and dry one side of the glass to form a clean surface, and the glass is tempered glass;

[0059] (4) Cover the clean surface of the glass with a cover plate with a hollow pattern. The hollow pattern is any design style among irregular geometric fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com