Welding machine for overlap edge of hot-melt coiled material

A lap joint edge and welding machine technology, applied in the field of waterproofing, can solve problems such as uneven physical strength, skills, and professional ethics of workers, restrictions on the realization of product functionality, and lax baking and sealing of lap joints, so as to improve the welding effect , Improve welding efficiency and ensure the effect of baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

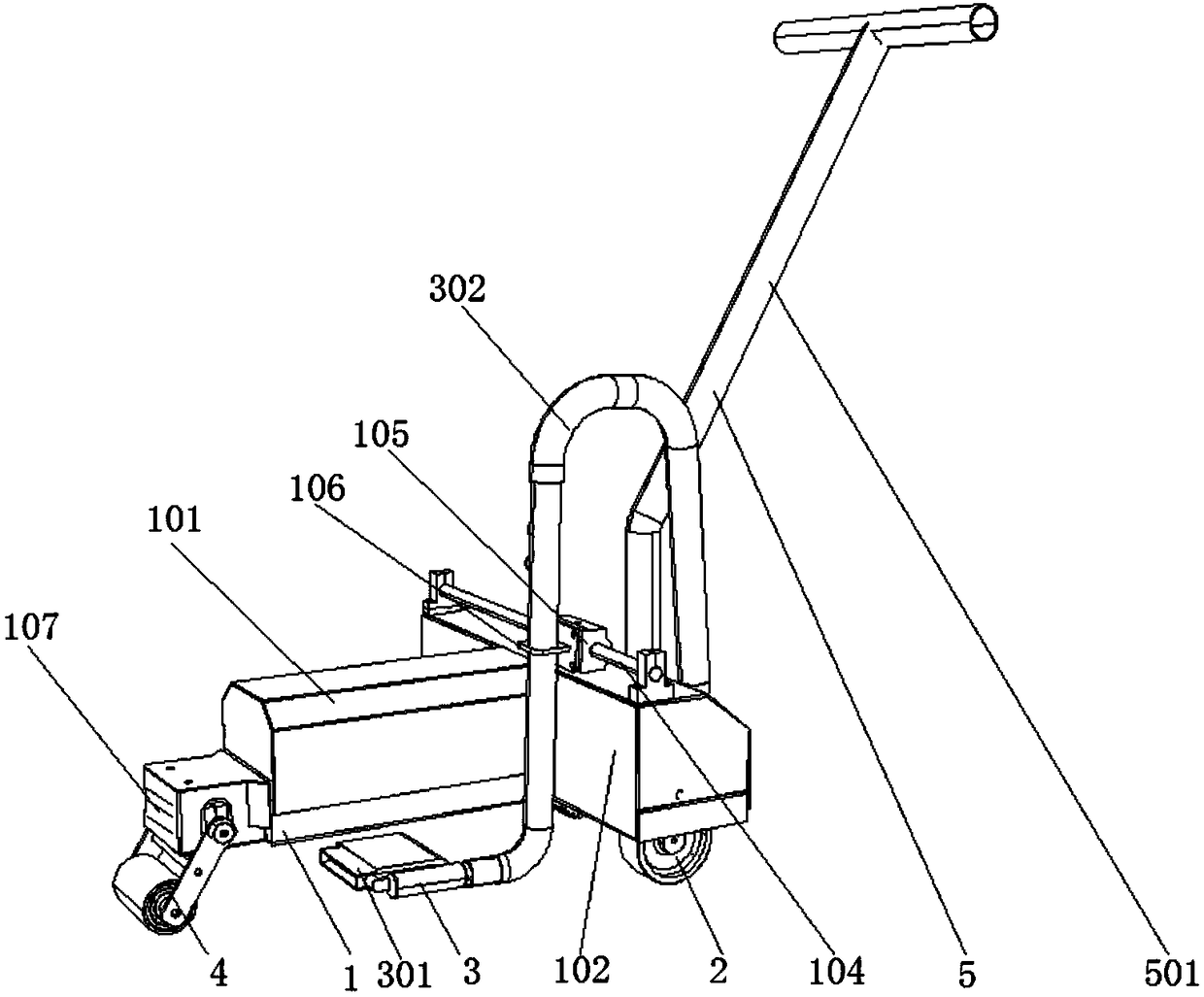

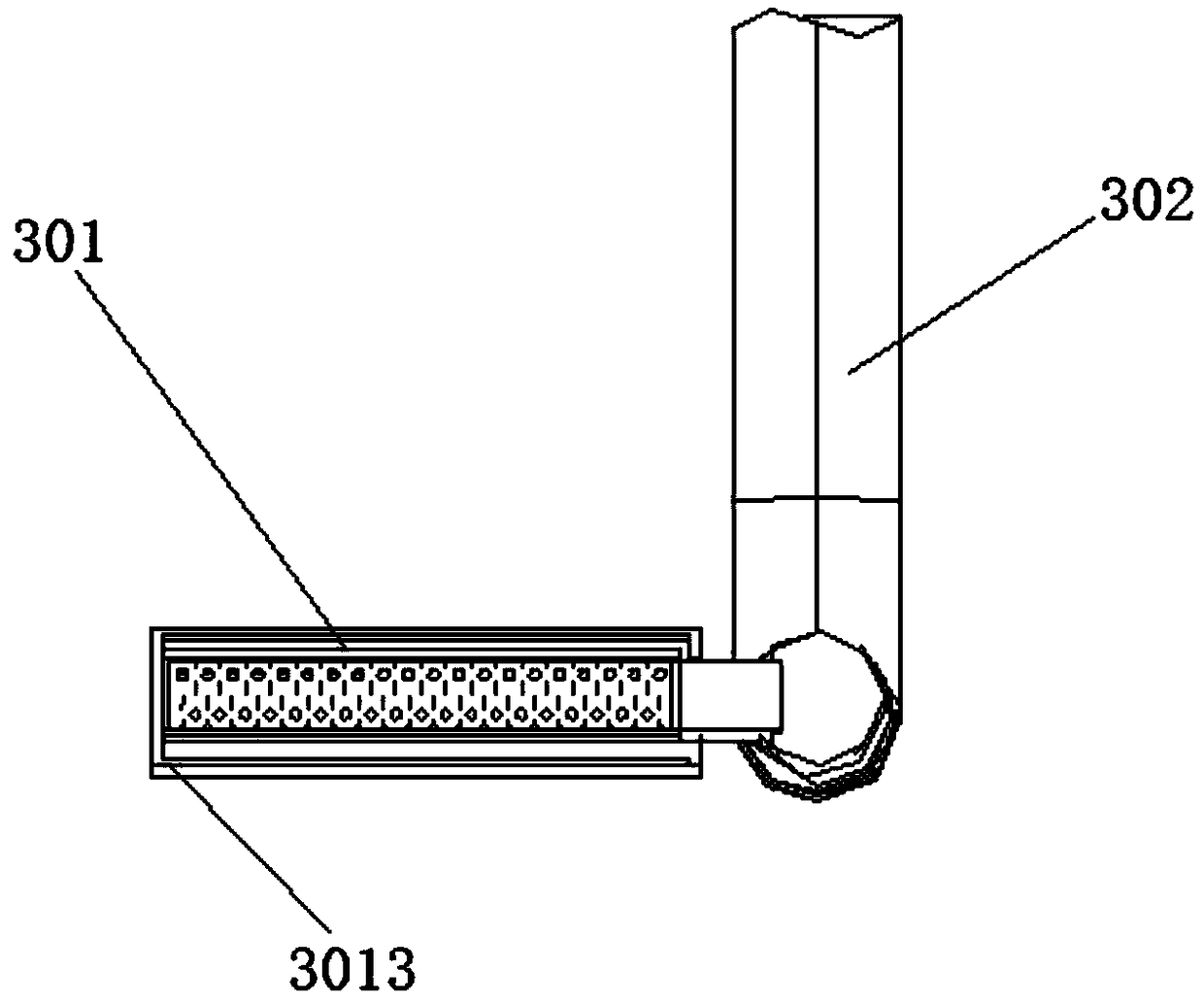

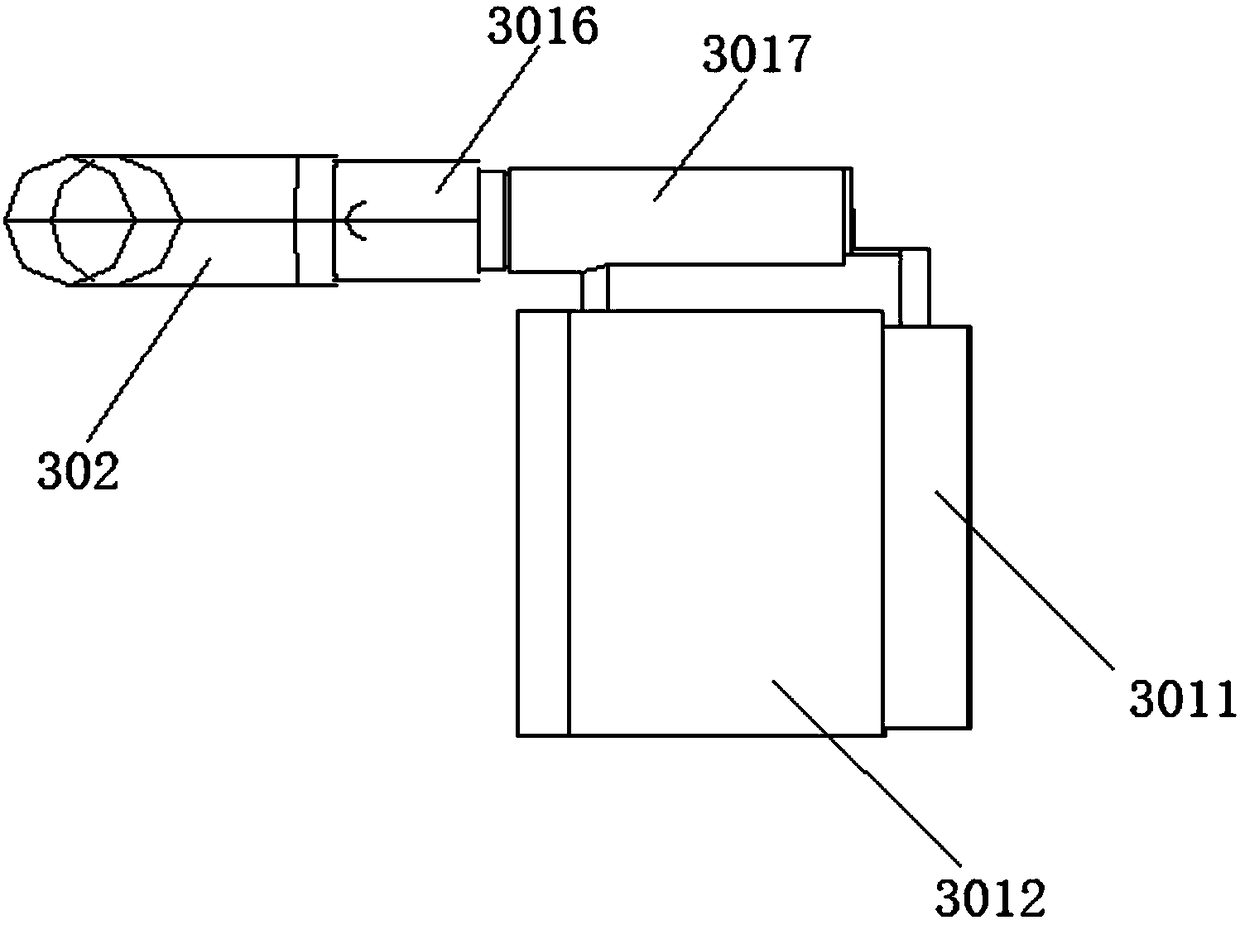

[0089] figure 1 A schematic structural diagram of a hot-melt coil lap edge welding machine according to an embodiment of the present invention is shown. figure 2 A front view of a combustion head according to an embodiment of the invention is shown. image 3 A top view of a combustion head according to an embodiment of the invention is shown. Figure 4 A schematic exploded structure diagram of a hot-melt coil lap edge welding machine according to an embodiment of the present invention is shown. Figure 5 A schematic exploded structure diagram of a hot-melt coil lap edge welding machine according to an embodiment of the present invention is shown. Figure 6 A schematic diagram of the explosion structure of the combustion head according to an embodiment of the present invention is shown.

[0090] The hot-melt coil lap edge welding machine includes a frame 1, a driving unit 2, a burner 3, a compacting unit 4, a guiding device 5 and a control unit 6;

[0091] The vehicle fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com