A welding method of stainless steel plate for thermal neutron shielding

A technology of thermal neutron shielding and stainless steel plate, applied in the field of materials, can solve the problems of high-boron stainless steel with complex process, complex metallurgical process, and high production cost, and achieve the effects of small welding deformation, simple metallurgical process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The composition of high-boron stainless steel is Cr 16.00%, Ni 14.50%, Mn 0.20%, Si 2.00%, B 0.50% by mass percentage, and the rest is Fe and unavoidable impurities; the composition of the boron-free stainless steel is by mass percentage It is Cr 16.00%, Ni 14.50%, Mn 0.20%, Si 2.00%, the rest is Fe and unavoidable impurities; the thickness of both is 2mm;

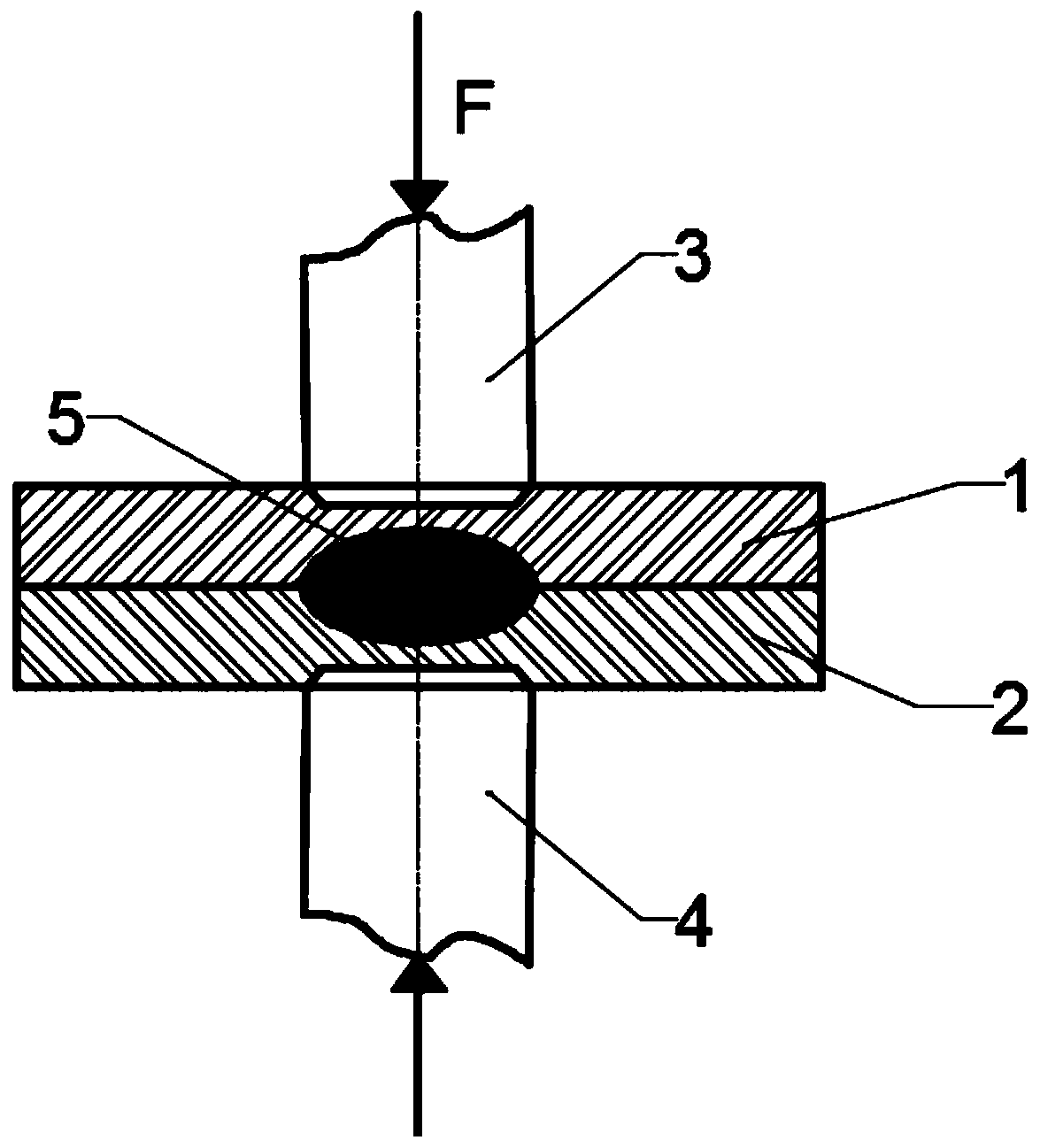

[0038] Stack the high-boron stainless steel plate and the boron-free stainless steel plate, and then press them with the upper electrode rod and the lower electrode rod; the direction of the pressing force of the upper electrode rod and the lower electrode rod is perpendicular to the high-boron stainless steel plate and the boron-free stainless steel plate; adopt The resistance spot welding method is used for welding, and the solder joint is cooled by cooling water during welding; the welding time is 0.16s, the welding current is 7.5kA; the voltage is 380V, and the cooling water flow rate is 3L / min; stainless steel ...

Embodiment 2

[0043] Method is with embodiment 1, and difference is:

[0044] (1) The composition of high-boron stainless steel is Cr 19.00%, Ni 9.00%, Mn 2.00%, Si0.20%, B 2.25% by mass percentage, and the rest are Fe and unavoidable impurities; the composition of the boron-free stainless steel Cr 19.00%, Ni 9.00%, Mn 2.00%, Si 0.20% by mass percentage, the rest is Fe and unavoidable impurities; both thicknesses are 2.5mm;

[0045] (2) The welding time is 0.18s, the welding current is 7.0kA; the cooling water flow rate is 4L / min;

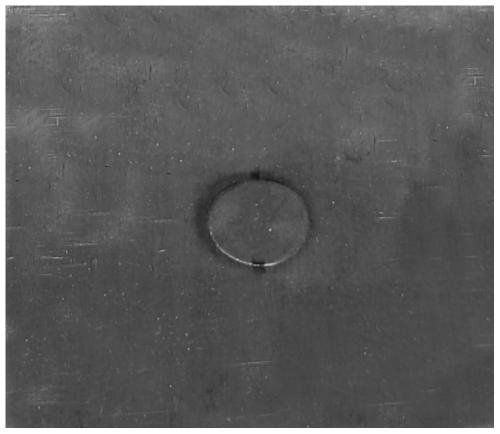

[0046] (3) The nugget diameter of the resistance spot welding joint is 4.8mm, the maximum tensile shear force is 3.32kN, and the indentation rate is 9%; the spot welding indentation of the resistance spot welding joint is flat and uniform, without cracks and the indentation depth is moderate, There is no splash on the surface and inside of the joint, no shrinkage cavity defect, and the joint fracture mode is nugget peeling; the appearance is as follows image ...

Embodiment 3

[0049] Method is with embodiment 1, and difference is:

[0050] (1) The composition of high-boron stainless steel is Cr 17.00%, Ni 10.50%, Mn 1.0%, Si 1.00%, B 1.25% by mass percentage, and the rest are Fe and unavoidable impurities; the composition of the boron-free stainless steel Cr 17.00%, Ni 10.50%, Mn 1.0%, Si 1.00% by mass percentage, the rest is Fe and unavoidable impurities; both thicknesses are 1mm;

[0051] (2) Welding time is 0.14s, welding current is 8.0kA; cooling water flow rate is 2L / min;

[0052] (3) The diameter of the end face of the upper electrode rod and the lower electrode rod is 8mm;

[0053] (4) The pressure of the upper electrode rod and the lower electrode rod on the high-boron stainless steel plate and the boron-free stainless steel plate is 4.5kN;

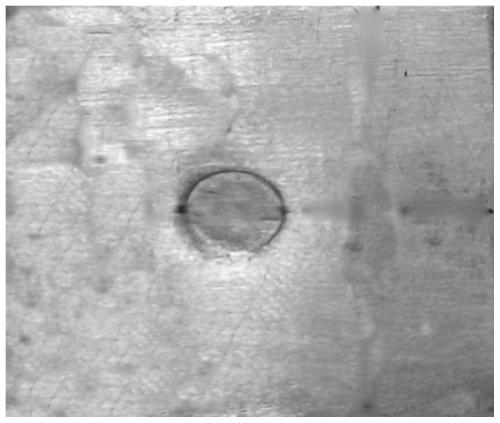

[0054] (5) The nugget diameter of the resistance spot welding joint is 4.5mm, the maximum tensile shear force is 3.2kN, and the indentation rate is 6%; the spot welding indentation of the resistance s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com