Die for automobile part

A technology for auto parts and molds, which is applied in the field of auto parts processing, can solve the problem that auto parts are not easy to take out, and achieve the effects of easy taking out, speeding up cooling speed, and avoiding low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

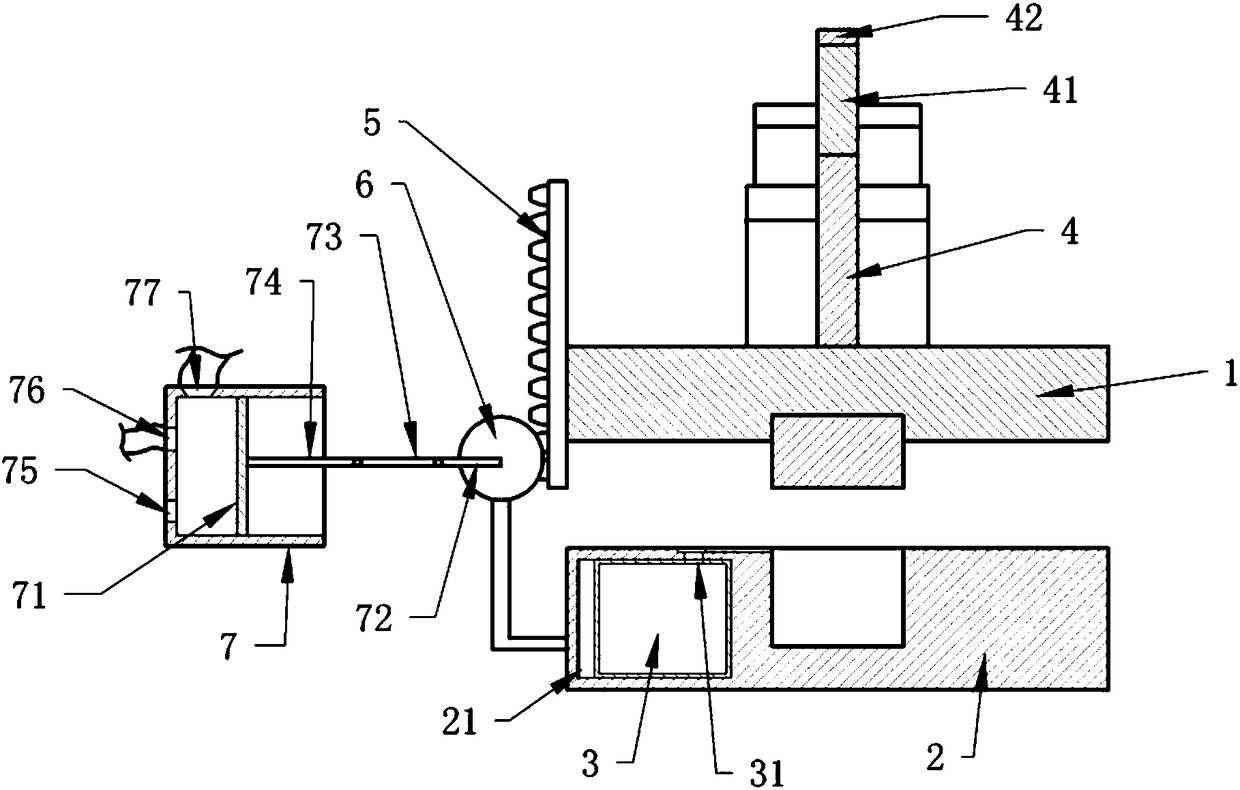

[0032] Further detailed explanation through specific implementation mode below:

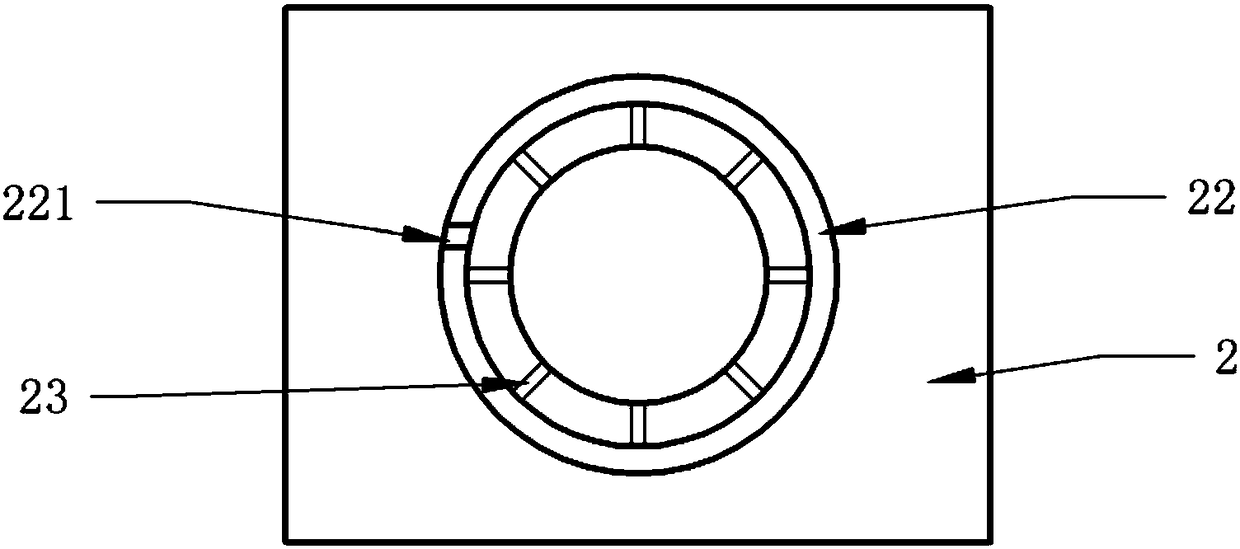

[0033] The reference signs in the drawings of the description include: upper punch 1, lower die 2, feed bin 21, feed trough 22, feed port 221, feed guide trough 23, storage air bag 3, discharge port 31, Screw rod 4, mounting rod 41, stopper 42, rack 5, turntable 6, air tank 7, piston 71, first connecting rod 72, second connecting rod 73, third connecting rod 74, air inlet 75, outlet Air port 76, exhaust port 77.

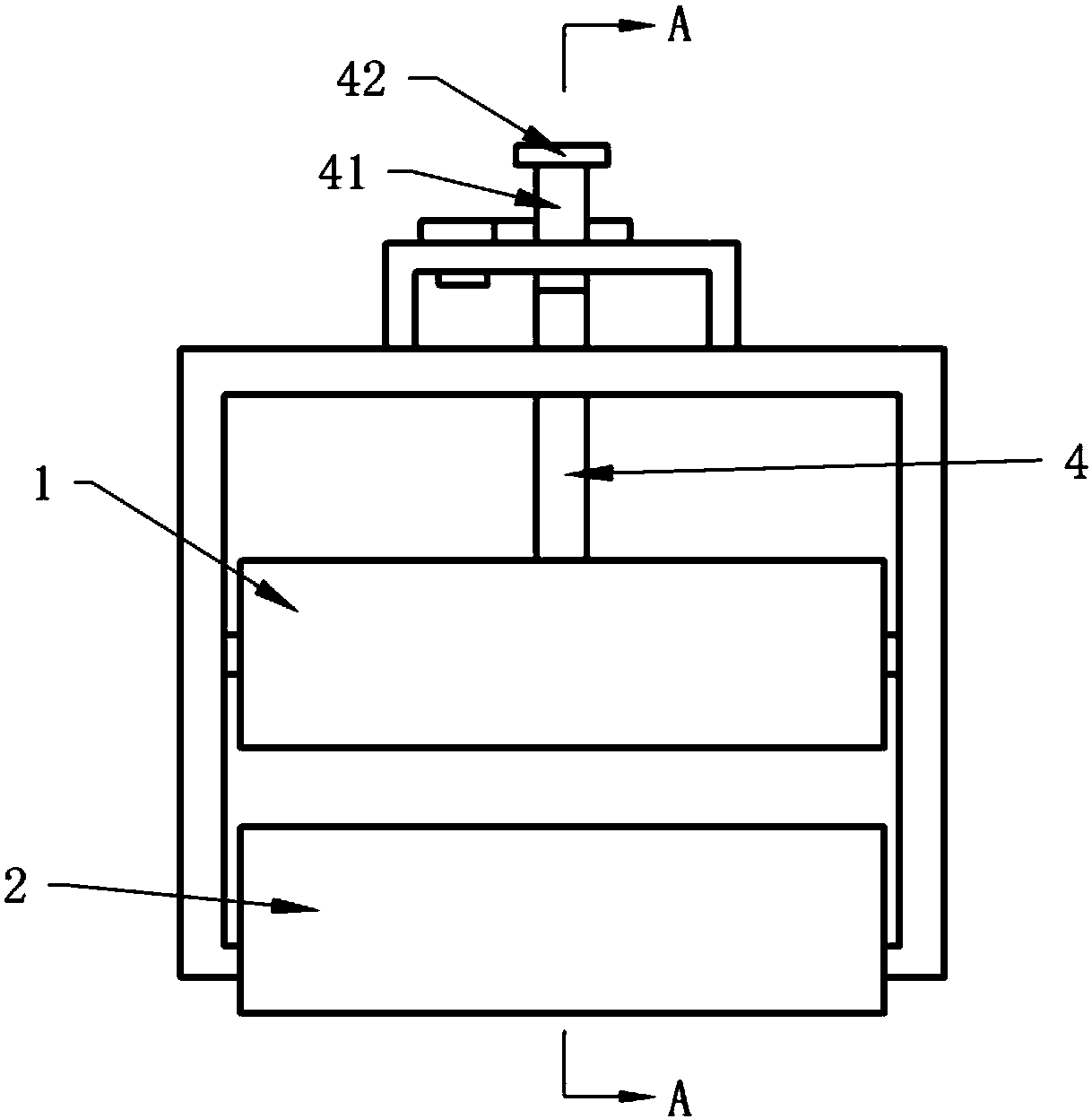

[0034] The embodiment is basically as attached figure 1 Shown:

[0035] The mold for auto parts includes an upper punch 1 and a lower die 2 matched with the upper punch 1, and also includes a bracket arranged in an inverted U shape. The bracket includes two vertical plates and a horizontal plate on the top of the two vertical plates. Plate, riser are installed on the left and right side walls of lower die 2 respectively. A side where the two vertical plates are close to each other i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com