Automobile engine nacelle curb girder front part with reinforced energy absorbing structure

A technology for engine compartments and energy-absorbing structures, applied in substructures, vehicle components, transportation and packaging, etc., can solve the problems of bending energy absorption, insufficient energy absorption, and increased costs, and achieve the effect of easy stamping and reasonable block division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

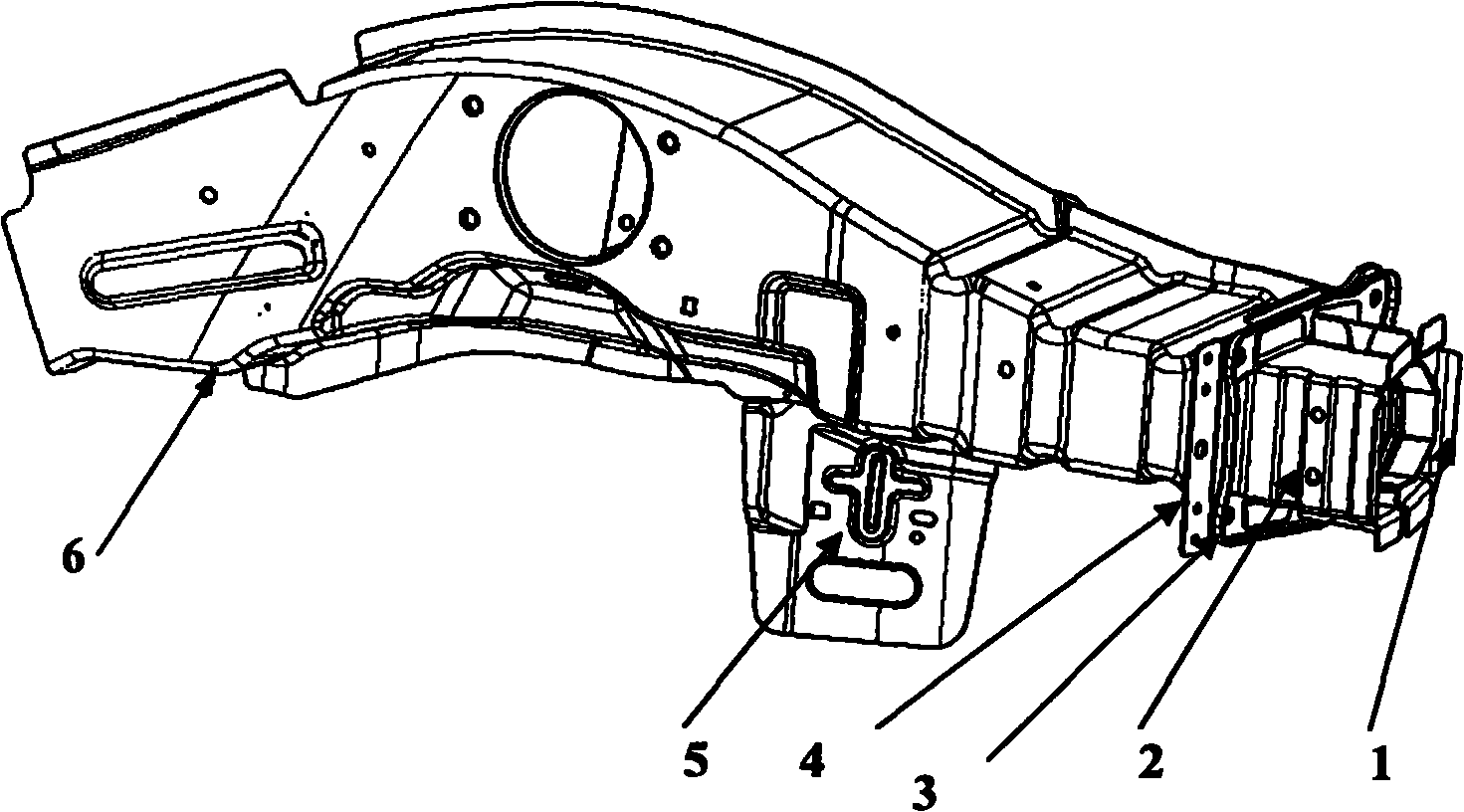

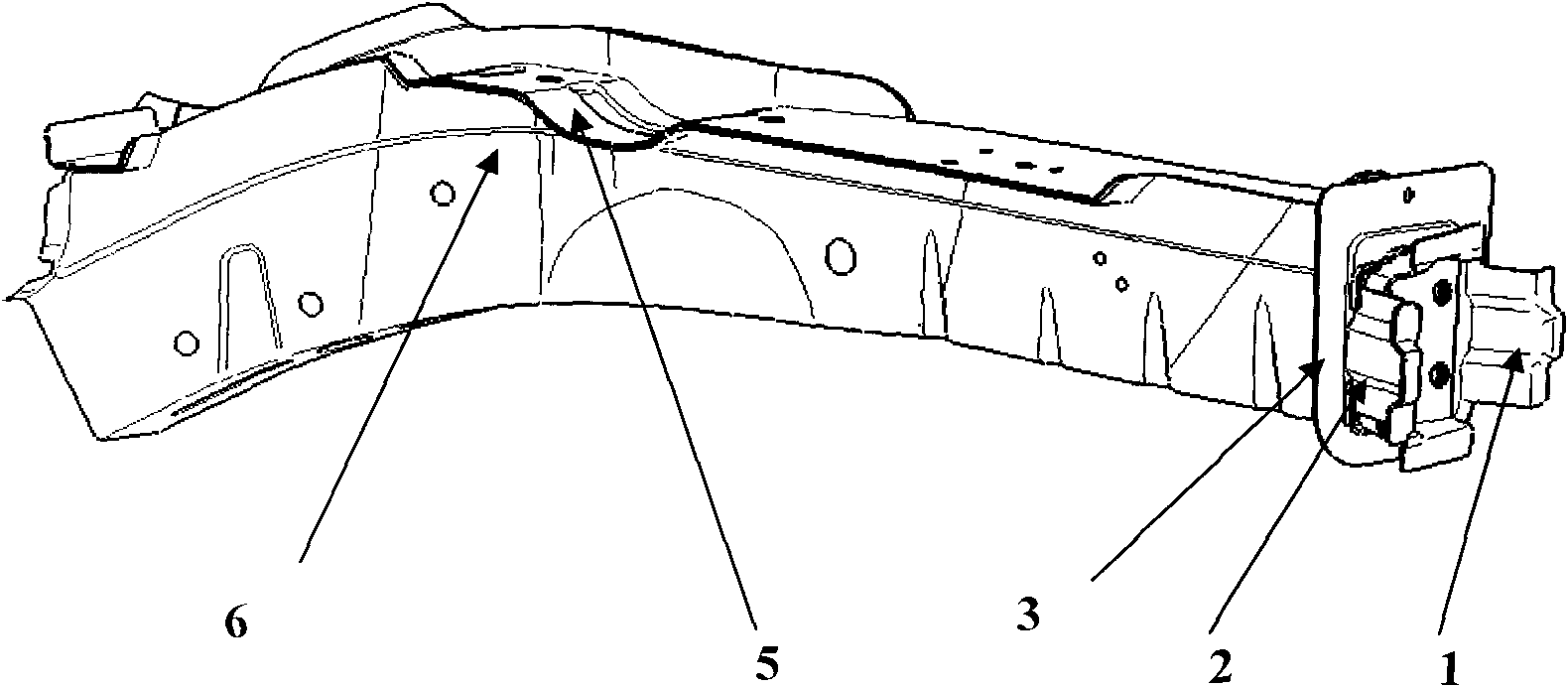

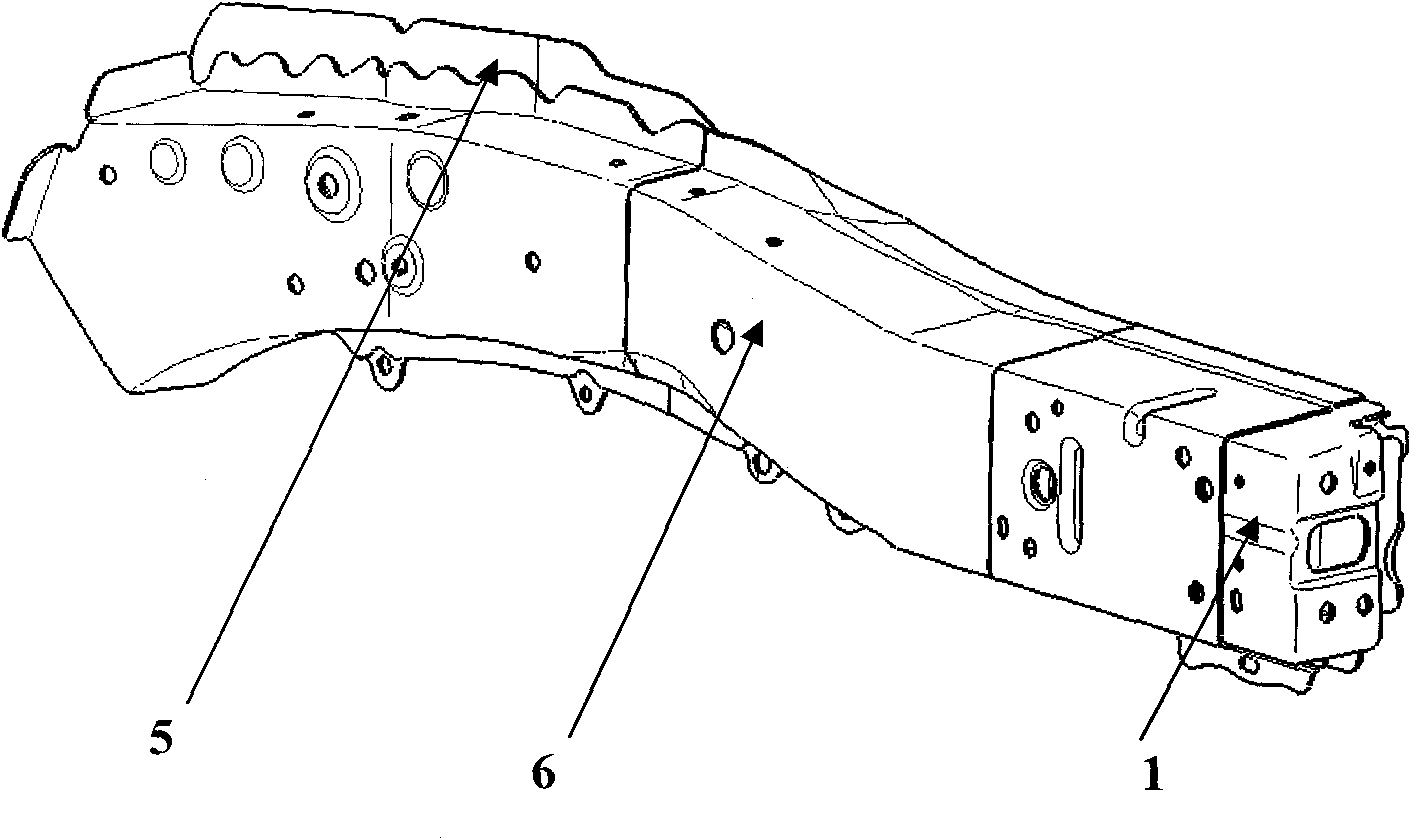

[0023] Referring to Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7 and Fig. 8, a car engine compartment side beam front section with a reinforced energy-absorbing structure includes the front section body 6, and the front section of the outer sealing plate connected to the lower part of the front section body. Plate 5, the front lock plate 4 connected to the right end of the front section body, the front crash box support 3 connected to the front lock plate; one end of a front crash inner box 1 and a front crash outer box 2 are all connected to the front crash box support Seat 3 is connected, the front collision inner box is relatively buckled with the front collision outer box, and the front collision inner mouth box is located inside the mouth of the front collision outer box, forming a box-in-box structure to ensure sufficient energy absorption during offset collisions ; In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com