A special school bus seat frame for students

A technology of seat frame and school bus, applied in the field of school bus seat frame for students, can solve the problems of uneven distribution of structural strength of backrest frame, injury to students and occupants, stripping of steel bars, etc. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

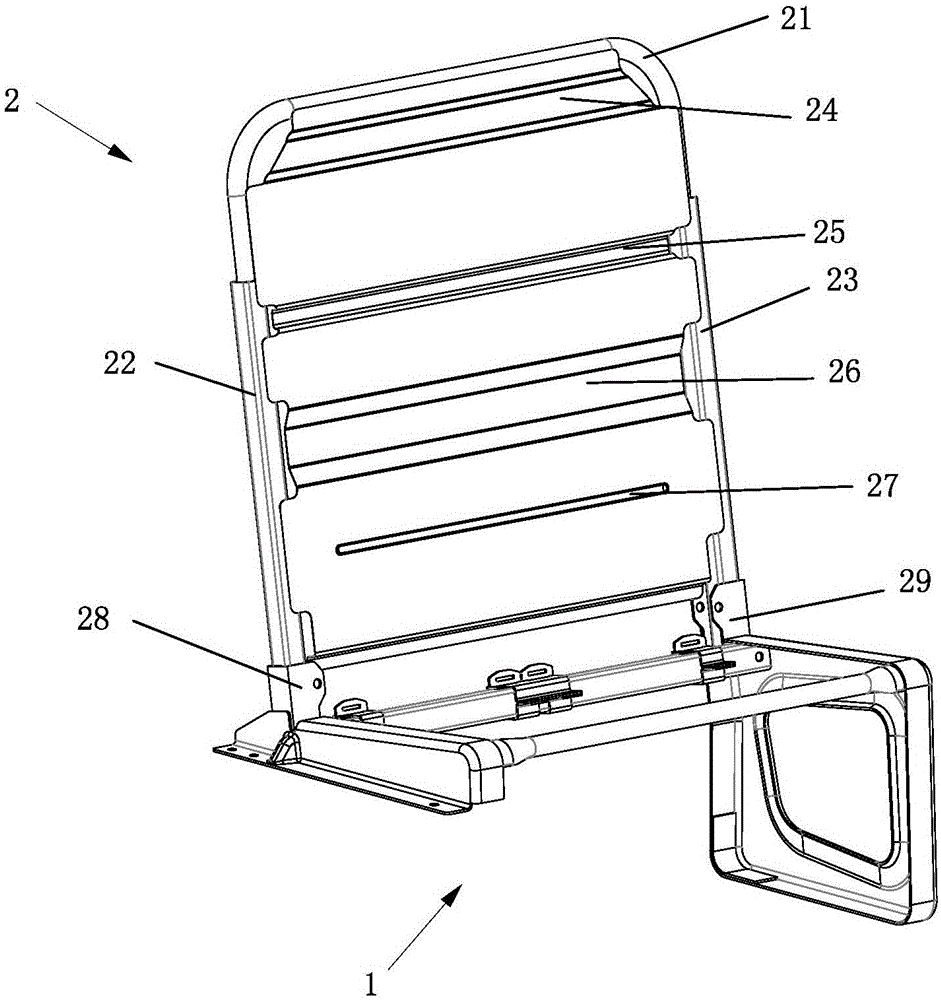

[0017] as attached figure 1 As shown, a school bus seat frame dedicated to students includes a cushion frame 1, a back frame 2 connected to the seat frame 1 through a connector, the back frame 2 includes an outer frame, and a back board fixedly arranged in the outer frame, and the outer frame includes a curved Pipe 21, a first connecting pipe 22 connected to one end of the elbow 21 at one end, a second connecting pipe 23 connected at the other end of the elbow 21 at one end, the upper part of the leaning plate is connected with the elbowing pipe 21, and the left and right sides of the leaning plate They are respectively connected with the first connecting pipe 22 and the second connecting pipe 23, and the backing plate is an integral structure. In order to further improve the strength of the school bus seat frame, the backing plate has a first reinforcement portion 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com