Adjustable particle size circulation stone crushing device

A particle size, crushed stone technology, applied in grain processing and other directions, can solve the problems of lack of separation, one-time crushing of ore, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

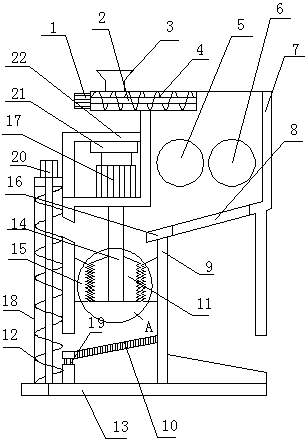

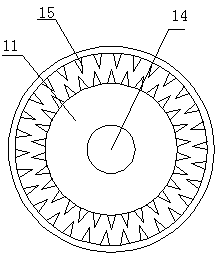

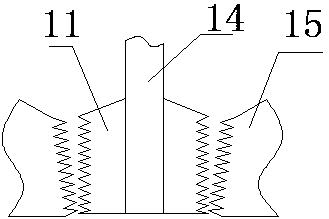

[0017] Such as Figure 1~3 As shown, a circulating crushing device with adjustable particle size includes a machine body 7, a feeding cylinder, an active crushing roller 6 and a driven crushing roller 5. A crushing cavity is arranged inside the body 7, and an inlet There are active crushing roller 6 and driven crushing roller 5 in the crushing chamber below the feeding barrel, one end of the active crushing roller 6 is connected to the motor A through the reducer, and the active crushing roller 6 and the driven crushing roller 5 are meshed. A discharge port A is provided below the active crushing roller 6 and the driven crushing roller 5, and a filter screen 8 is provided at the upper end of the discharge port A, and the filter screen 8 is arranged obliquely;

[0018] A seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com