Substrate turnover tray

A technology for carrying discs and substrates, which is applied in the fields of instruments, nonlinear optics, optics, etc., and can solve problems such as substrate fragments and hindering the normal taking of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

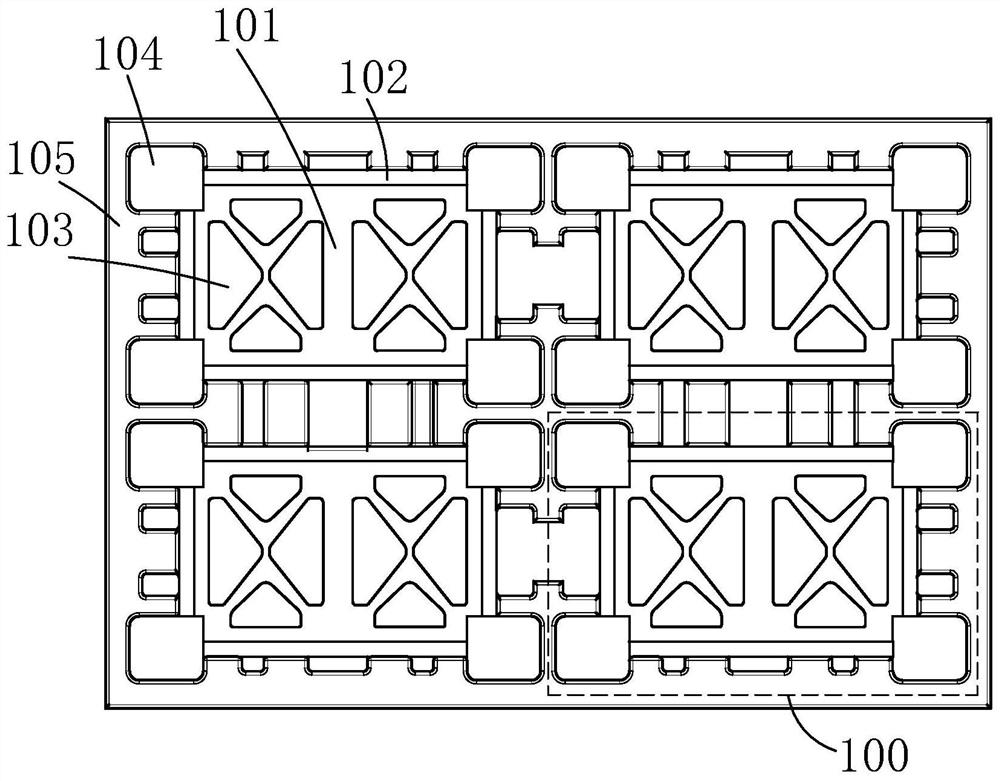

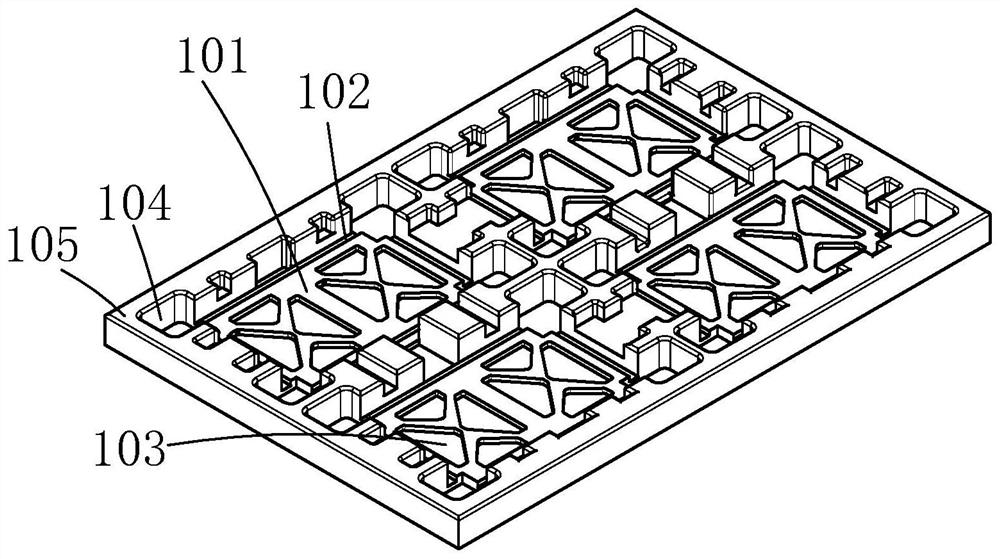

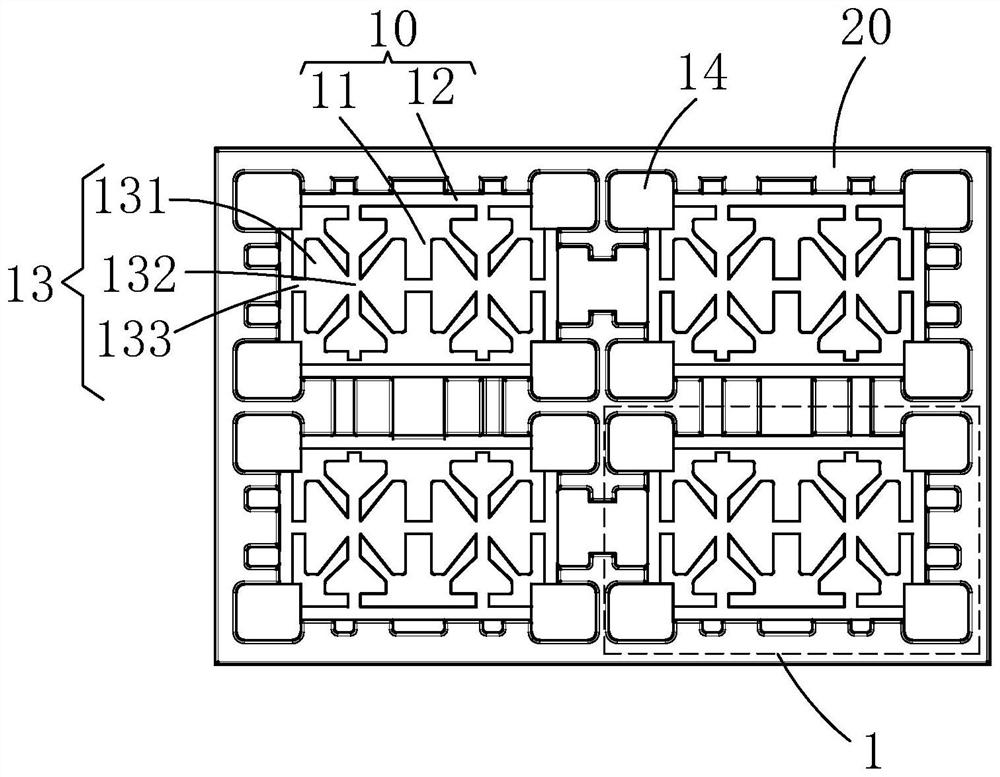

[0026] see image 3 , the present invention provides a substrate turnover tray, comprising: at least one tray 1, each tray 1 includes: a bottom surface 10 and a side wall 20 connected to the bottom surface 10 and surrounding the bottom surface 10; the bottom surface 10 includes: a bearing boss 11 and a communication groove 12 extending around the bearing boss 11, a first groove 13 is formed in the bearing boss 11, a second groove 14 is formed in the side wall 20, The concave direction of the communication groove 12 , the first groove 13 and the second groove 14 is perpendicular to the bottom surface 10 , and the first groove 13 and the second groove 14 are all in communication with the communication groove 12 .

[0027] Specifically, in some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com