LCD printing equipment

A technology of printing equipment and liquid crystal display, which is applied in the field of equipment in the flat panel display industry, to achieve the effects of preventing damage, improving equipment grafting rate, and improving equipment yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

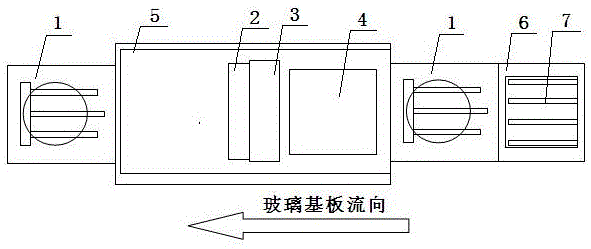

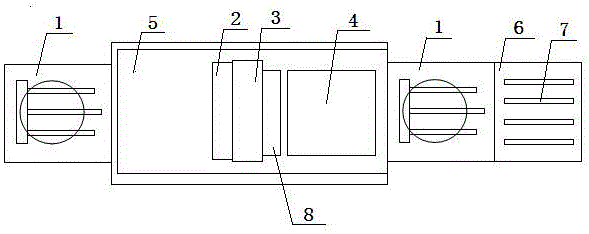

[0051] Such as image 3 As shown, the first arrangement of the workpiece cleaning device of the linear liquid crystal display printing equipment of the present invention includes a robot 1 , a printing machine 5 , a receiving platform 7 and a workpiece cleaning device 8 . The robot 1 is located at the end of the long axis of the printing machine 5, and the receiving platform 7 is located on one side of the robot 1, and the robot 1, the printing machine 5 and the receiving platform 7 are arranged in a straight line.

[0052] The printing machine 5 includes A wheel 2, printing wheel 3, and printing platform 4. The printing wheel 3 can rotate on a fixed axis at the end of the printing platform 4 through the printing wheel control system, and can also roll in a straight line on the printing platform 4; The side above one end of the platform 4 is arranged parallel to the printing wheel 3 .

[0053] Such as Figure 7-10As shown, the workpiece cleaning device 8 includes a main engi...

Embodiment 2

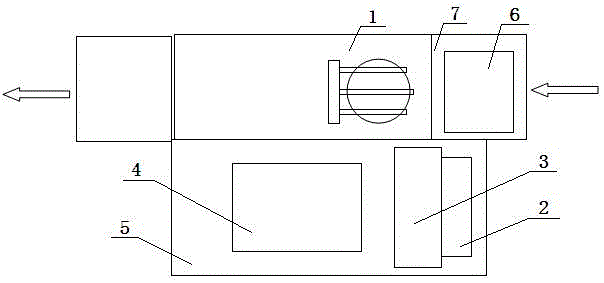

[0056] Such as Figure 4 As shown, the first arrangement of the workpiece cleaning device of the character-shaped liquid crystal display printing equipment of the present invention is different from Embodiment 1 in that the robot 1 is located at the short axis end of the printing machine 5, and the receiving platform 7 is located at the end of the robot 1. On one side, the robot 1, the printing machine 5 and the receiving platform 7 are arranged in an inverted font.

[0057] Operation mode: the workpiece cleaning device 8 in this mode adds a set of walking devices. Before the glass substrate 6 is printed, the workpiece cleaning device 8 is opened and then moves forward on the walking guide rail 13 for cleaning; when there is no glass substrate 6 on the printing platform 4 , the workpiece cleaning device 8 moves forward to clean the printing platform 4 .

Embodiment 3

[0059] Such as Figure 5 As shown, the second arrangement of the workpiece cleaning device of the linear liquid crystal display printing equipment of the present invention is different from the embodiment 1 in that it also includes a walking guide rail 13 . The walking guide rail 13 is arranged on the printing platform 4, parallel to the moving direction of the printing wheel 3; the cleaning head of the workpiece cleaning device of the workpiece cleaning device is arranged on the walking guide rail 13, and an independent driving device is used.

[0060] The mode of operation is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com