System and method for monitoring leakage of fuel evaporation system

A fuel evaporation system and leakage hole technology, which is applied to the charging system, engine components, machines/engines, etc., can solve the oil and gas leakage, and it is impossible to distinguish whether it is only the pressure curve under the reference hole or contains and weakens the sealing of the fuel evaporation system. To reduce pipeline disconnection and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

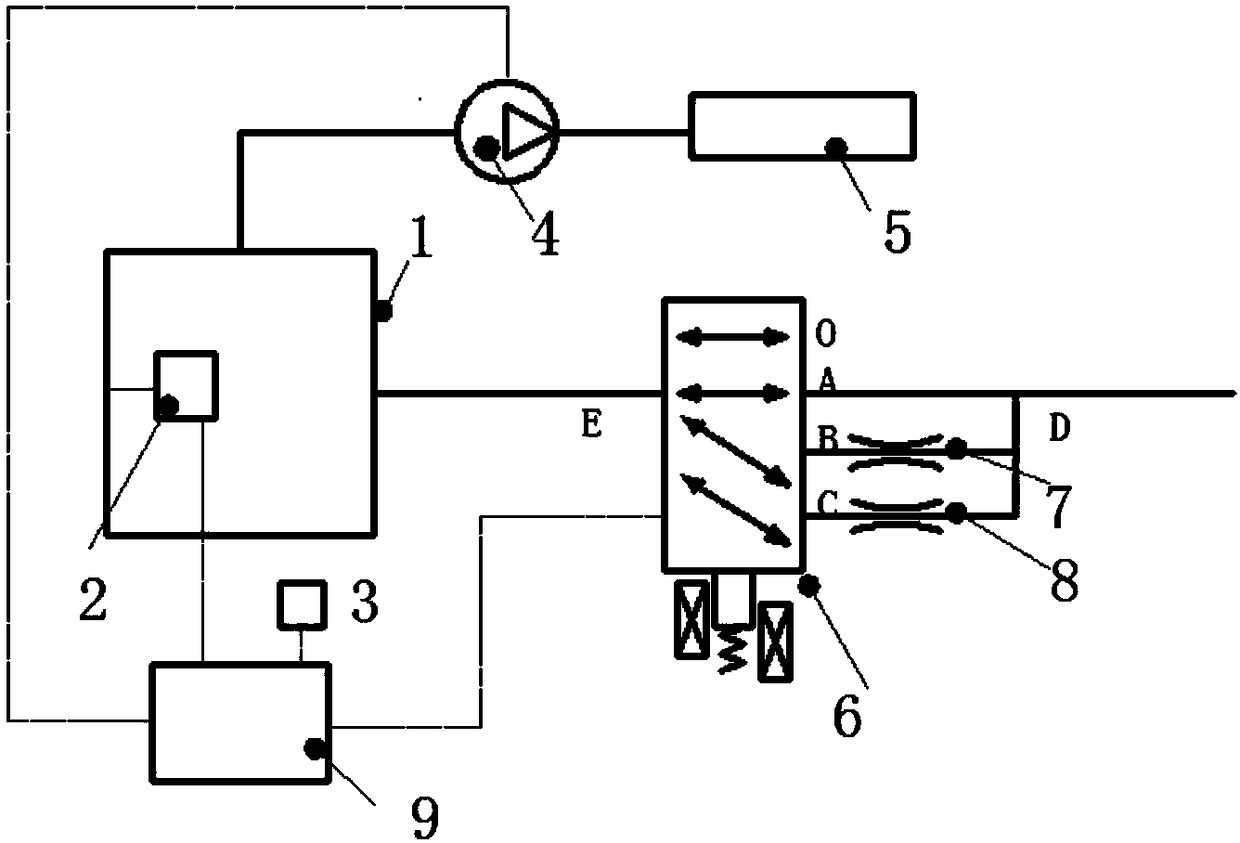

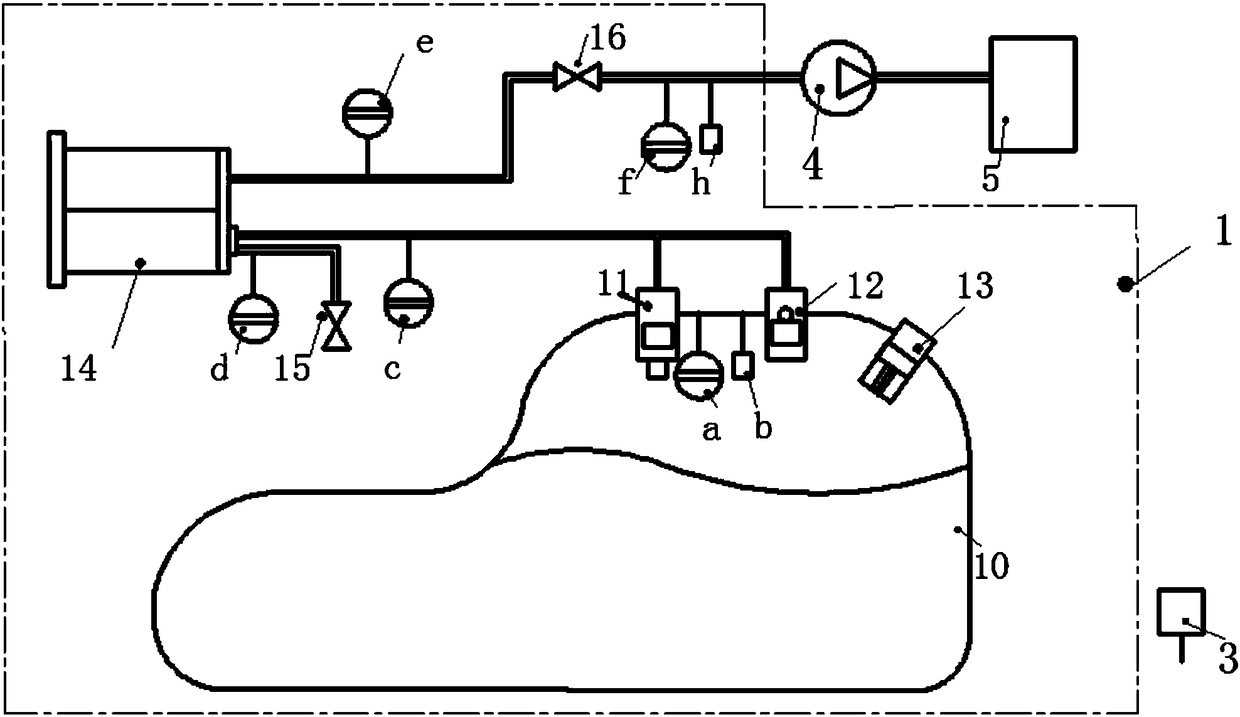

[0019] See attached figure 1 , the system used for monitoring the leakage of the fuel evaporation system includes a fuel evaporation system 1, sensors are arranged in each section of the fuel evaporation system 1, including a pressure and temperature sensor group 2 installed in the fuel evaporation system 1 and a sensor set installed outside the fuel evaporation system 1 The temperature sensor 3 and the vacuum pump 4 are located between the fuel evaporation system 1 and the intake manifold 5. The reversing valve 6 is installed on the pipe outside the fuel evaporation system 1. The reversing valve 6 is provided with four channels: fuel evaporation system leakage hole Channel A, channel B installed with 0.5mm reference hole 7, channel C installed with 1mm reference hole 8, and cut-off channel O, the reversing valve 6 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com