Rotating target material capable of withstanding high-power sputtering, and preparation method of rotating target material

A rotating target, high-power technology, applied in the field of sputtering targets, can solve the problems of high-power sputtering, contamination of coating chambers and products, low bonding efficiency, etc., to reduce target surface nodules and target The material is broken down and the target material is cracked, which is convenient for manual operation and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

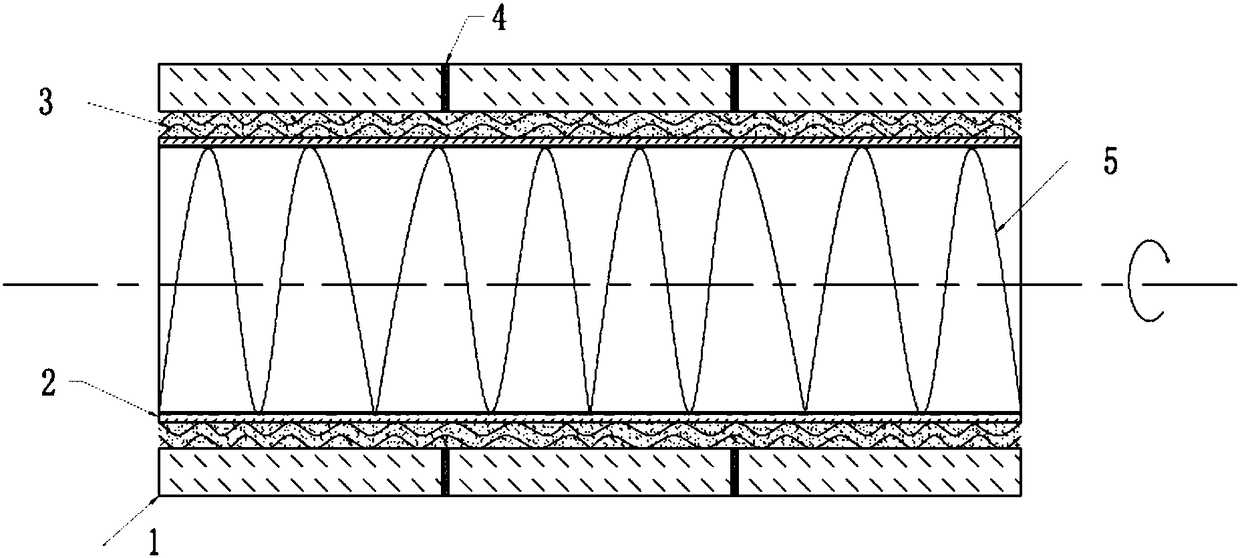

[0041] Such as figure 1 As shown, the Bang type magnetron sputtering rotating target of the present invention includes a stainless steel back tube 1 and 12 AZO ceramic targets 3 fixedly sleeved on the outer wall of the stainless steel back tube 1, wherein the two ends of the AZO target 3 are inverted C0.5 angle. The stainless steel back tube 1 is connected to the AZO ceramic target material 3 through a sandwich structure 2 composed of a bonding material and a metal mesh filled in the gap between the two, and the inner wall of the AZO ceramic target material 3 is connected to the outer wall of the stainless steel back tube 1 The gap is 0.35mm, and the target material 3 is separated from the target material 3 by a tetrafluoroethylene ring piece 4

[0042] Wherein, the metal mesh is a copper mesh.

[0043] Wherein, the bonding material is a graphene composite bonding material, which is composed of polymer resin and graphene in a mass ratio of 1.5:1.

[0044] Wherein, the polym...

Embodiment 2

[0053] Such as figure 1 As shown, the Bang type magnetron sputtering rotating target of the present invention includes a stainless steel back tube 1 and three sections of TZO ceramic target 3 fixedly sleeved on the outer wall of the stainless steel back tube 1, wherein the two ends of the TZO target 3 are inverted C0.5 angle. The stainless steel back tube 1 is connected to the TZO ceramic target material 3 through a sandwich structure 2 composed of a bonding material and a metal mesh filled in the gap between the two, and the inner wall of the TZO ceramic target material 3 is connected to the outer wall of the stainless steel back tube 1 The gap is 0.35mm, and the target material 3 is separated from the target material 3 by a tetrafluoroethylene ring piece 4 .

[0054] Wherein, the metal mesh is an aluminum mesh.

[0055] Wherein, the bonding material is a graphene composite bonding material, which is composed of polymer resin and graphene in a mass ratio of 1.5:1.

[0056]...

Embodiment 3

[0065] Such as figure 1 As shown, the Bang type magnetron sputtering rotating target of the present invention includes a stainless steel back tube 1 and five metal Ag targets 3 fixedly sleeved on the outer wall of the stainless steel back tube 1, wherein the two ends of the Ag target 3 are inverted C1 corner. The stainless steel back tube 1 and the Ag target material 3 are connected through a sandwich structure 2 composed of a bonding material and a metal mesh filled in the gap between the two, and the gap between the inner wall of the Ag target material 3 and the outer wall of the stainless steel back tube 1 is 0.35mm, and the target material 3 is separated from the target material 3 by a tetrafluoroethylene ring piece 4 .

[0066] Wherein, the metal mesh is an iron mesh.

[0067] Wherein, the bonding material is a graphene composite bonding material, which is composed of polymer resin and graphene in a mass ratio of 2:1.

[0068] Wherein, the polymer resin is room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com